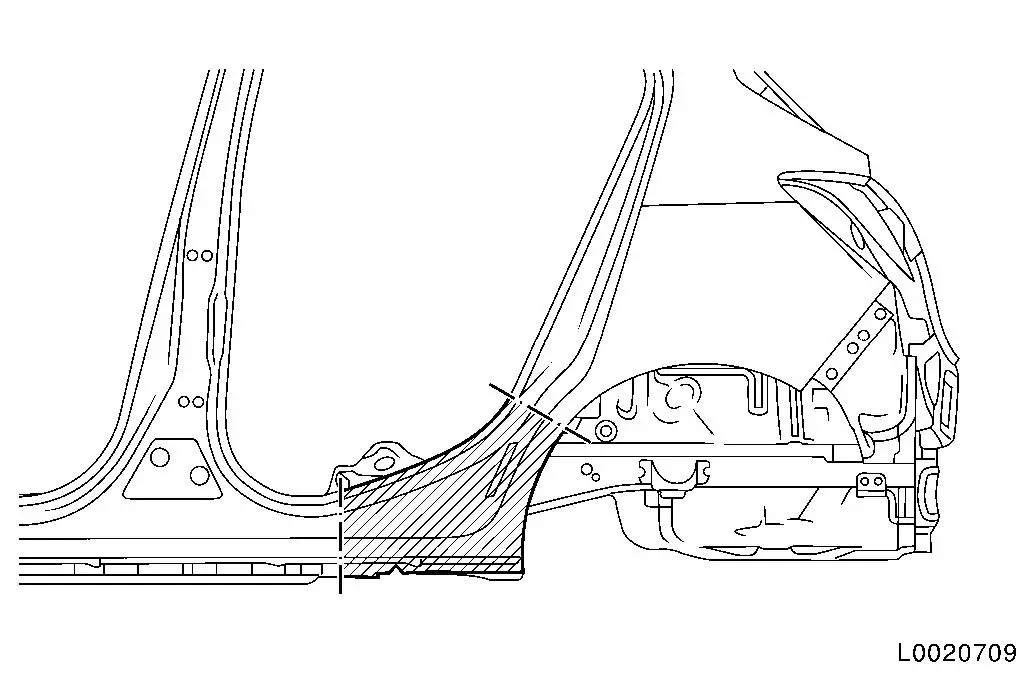

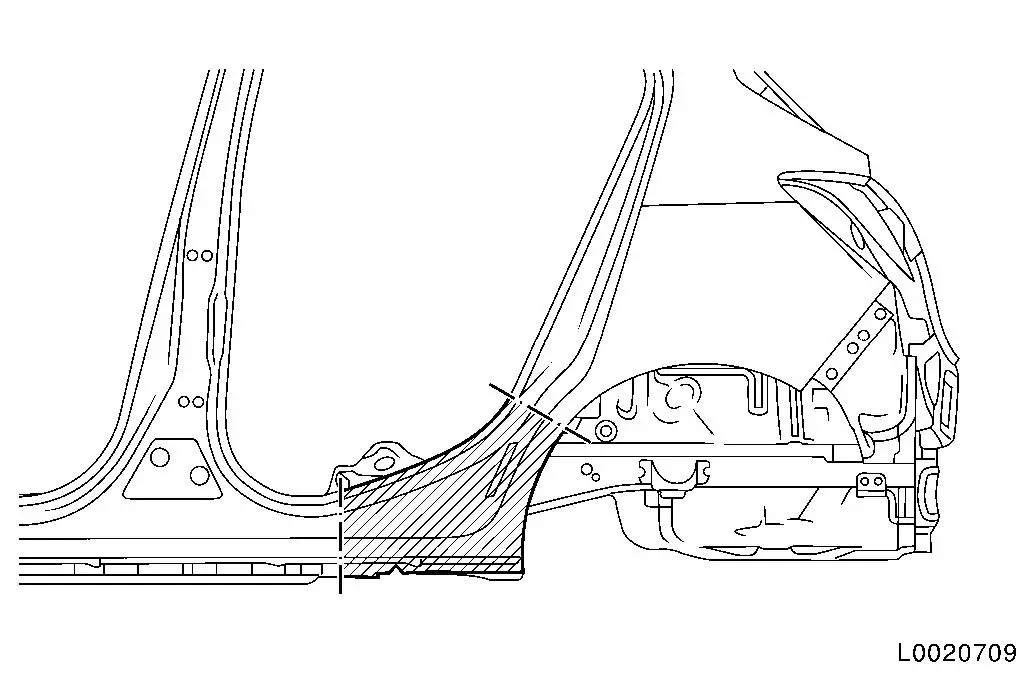

- Use your grinder and cutoff wheel to cut both at the same time

- Ensure the two panels are not touching all the way around, as they’ll expand and warp once heat from the weld is applied

- Use clamps to hold the panels in place and help maintain the gap and panel alignment

When should I replace my wheel arch panels?

The sooner you replace the outer wheel arch panel, the more likely you are to prevent the further spread of rust. As rust eats away at the inside of your panel, the paint will bubble and flake on the outside of your wheel arches. Installing wheel arch panels as soon as you notice any rust can help stop any further damage and save you money.

What to do if your wheel arches are rusting?

As rust eats away at the inside of your panel, the paint will bubble and flake on the outside of your wheel arches. Installing wheel arch panels as soon as you notice any rust can help stop any further damage and save you money. How to Repair Rusted Out Wheel Arches

What happens when you put wheel arch panels on a car?

As rust eats away at the inside of your panel, the paint will bubble and flake on the outside of your wheel arches. Installing wheel arch panels as soon as you notice any rust can help stop any further damage and save you money.

What is Dorman OE fix wheel arch repair panel?

This Dorman OE FIX wheel arch repair panel welds in place to directly replace the section of the fender that often rusts out first. It is precisely reverse-engineered to ensure original equipment quality, fit and durability.

Can you replace a wheel arch panel?

Repairing Your Wheel Arches If you only need to replace the outer skin — or wheel arch — it's a basic cut and weld process that you're looking at. If, on the other hand, you need to replace the inner wheelhouse too, the repair process is going to get a bit more involved.

How do you weld a wheel arch repair panel?

0:3812:44How to Weld in wheel arch rust repair panel (99-07 Ford f250) part 2 ...YouTubeStart of suggested clipEnd of suggested clipI usually just take a tool press it up against there you'll have to get in there some way you canMoreI usually just take a tool press it up against there you'll have to get in there some way you can always use your hands magnets clamps whatever I use it all whatever it takes to get it.

How do you glue a patch panel?

3:2711:40Glue On Automotive Door Bottoms with Panel Adhesive - No Welding!YouTubeStart of suggested clipEnd of suggested clipEarlier in the video i stated we were gonna use 3m structural adhesive or panel adhesive.MoreEarlier in the video i stated we were gonna use 3m structural adhesive or panel adhesive.

How do you fix a badly rusted wheel arch?

10:4122:59How to Repair a Rusted Wheel Arch - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo now they are hitting it with some weld through primer to seal up that metal that bare metal they'MoreSo now they are hitting it with some weld through primer to seal up that metal that bare metal they're going to hit the back of the that panel they're going to weld in with the same primer.

How do you weld a wheel well?

6:0921:36How to Repair a Rust Hole on a Wheel Well Arch - YouTubeYouTubeStart of suggested clipEnd of suggested clipI actually welded a couple pieces I got a bunch of square scrap pieces of sheet metal that is theMoreI actually welded a couple pieces I got a bunch of square scrap pieces of sheet metal that is the thickness of automotive sheet metal and I just snapped them together real quick to make a long piece.

What do wheel arch liners do?

Wheel Arch Liners can take over the function of an air curtain. In combination with Speed Lips and bumpers/air deflectors they become aerodynamically effective. It is also possible to use additional absorbers and special material combinations. This reduces noise in the interior and during pass-by even more effectively.

How do you apply panel bonding adhesive?

0:123:073M Tech Tips: Applying Panel Bond Adhesives - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd grind a bare metal. I need to make sure that I spread this the adhesive out to cover all thatMoreAnd grind a bare metal. I need to make sure that I spread this the adhesive out to cover all that bare metal before I put the panels together a plastic body filler spreader.

Is Panel bond stronger than Weld?

Welding Versus Body Panel Adhesive Metals also undergo less distortion and are at a lower risk of damage, making the bond strong and durable. What is this? On the other hand, body panel adhesive is gluing together automotive body parts of different or similar materials using an adhesive bond material.

What do you use to glue on rocker panels?

0:0517:28How to Glue On Car/Truck Rocker Panels - No Welding! - YouTubeYouTubeStart of suggested clipEnd of suggested clipIn the previous videos above we removed the spot welds separated the rusted rocker and fixed up theMoreIn the previous videos above we removed the spot welds separated the rusted rocker and fixed up the inner panel today we're going to glue the new one into place with sem impact resistant structural

Is rust worth repairing?

In the majority of these situations where important equipment necessary for the automobile's functioning is impacted, repairing rust is not worth it due to the danger of driving a vehicle with weakened structures.

Is a rusty wheel arch an MOT failure?

A car WILL pass an MOT with tape over rusty wheel arches. To fail an MOT the rust needs to be deemed as "structural". A wheel arch is not structural. Nor does it pose a threat to pedestrians.

Can rust around wheel wells be fixed?

Luckily, wheel well rust repair is on the cheaper side of things. The most economical choice, of course, is to fix the problem yourself. If you don't already have the required materials, they will cost around $60 to purchase.

How to prevent heat damage to car interior?

2) To prevent heat damage to the car’s interior, remove the seats, peel back the carpets from the area around the inner fender, and buy yourself a candy bar with the change you found under the seat. Jack up and support the corner of the car, and remove the wheel.

Can you use Moss panels to repair sheet metal?

Using these pre-shaped panels is infinitely preferable to trying to repair rusted sheet metal from sheet-stock , so, even if the job requires the services of a professional body shop, Moss repair panels cut costs and make for a much better job.

Does Moss Motors sell rust repair panels?

As most of our readers know, Moss Motors sells a wide range of Rust Repair Panels. We are often asked how easy it is for the amateur to install them. Provided you have the right equipment, a reasonable level of mechanical aptitude and a car that is not totally rusted out, the procedure is quite straightforward. Using these pre-shaped panels is infinitely preferable to trying to repair rusted sheet metal from sheet-stock, so, even if the job requires the services of a professional body shop, Moss repair panels cut costs and make for a much better job.

Is it better to cut a fender with a disc grinder or a welding torch?

Be sure to allow for the W of the fender that has to cover the lip of the repair panel! Cutting with a disc grinder is much better than using your welding torch, because the heat will warp the fender. Care is important when cutting; one wrong cut and you’ve got another repair job!

How to make your car not twist when removed?

Start by having your vehicle on a solid surface, like a concrete slab, and then put jack stands under each corner of the frame.

Can you put a slip on panel over an existing panel?

If you’re buying a slip-on panel to go over top of an existing panel, you will still need the grinding discs to help remove as much existing rust as possible prior to installing the new panel. Most slip-on panels can either be welded, riveted, or secured via an automotive adhesive.

Can you repair rust on a car?

Repairing rust on your vehicle’s body, from rocker panels to wheel arches, can be a fairly straight forward job if you plan appropriately. You’ll obviously want high quality replacement panels to start with, but that aside, here are a few simple tips to help you plan for, and complete, a successful sheetmetal replacement job.