Steps

- Draw a circle around the damaged area.

- Drill a pilot hole in the circle so a bigger Unibit can easily drill into the aluminum.

- Using a preferred method cut out the aluminum within the circle drawn around the damage. Debur the newly cut hole.

- Cut out a circular patch from a sheet of aluminum that is the same thickness and the original aircraft skin.

How do you fix a hole in an aluminum airplane?

Drill a pilot hole in the circle so a bigger Unibit can easily drill into the aluminum. Using a preferred method cut out the aluminum within the circle drawn around the damage. Debur the newly cut hole. Cut out a circular patch from a sheet of aluminum that is the same thickness and the original aircraft skin.

How to fix an airplane patch that has a dope?

After removing the dope, cut your patch out of new fabric after carefully measuring the dope-free area. Use pinking shears and make sure the patch is of the same weight fabric that is on the airplane and that it has the required overlap. To prevent future frustration, cut the patch from very smooth fabric because it’s difficult to remove wrinkles.

How to get rid of holes in the aircraft skin?

Remove the patch from the aircraft skin and deburr all the holes both on the patch and on the aircraft skin.

What does it take to replace aircraft fabric?

Replacement of aircraft fabric is a big job because it never is just a plain recover job-there may be repairs required along with the preparation involved, such as completely disassembling the fuselage frame and sand blasting the fuselage, inspecting for damage and rust, and applying dope proof primer.

How do you repair fabric on a plane?

32:5247:17How to Inspect and Repair All Aircraft Fabric Systems - Stewart SystemsYouTubeStart of suggested clipEnd of suggested clipIf you've got a small patch you can just wet glue it you can put wet glue right on it lay the patchMoreIf you've got a small patch you can just wet glue it you can put wet glue right on it lay the patch right down in it put more glue overtop wipe off the excess. And you're done it's in here.

Can you repaint aircraft fabric?

You can do anything you want with the paint scheme. Some of what said is true but you can make it look brand new if that's what you want. Remember paint adds weight. With any luck it's polytone or dope.

How much does it cost to recover a fabric airplane?

Yes, that's correct, the price charged by most professionals to cover an airplane will range between $8,000-$12,000. If you cover your airplane with fabric according to the instruction manual (this is important) the fabric and coatings will have a service life of about 15-20 years.

How do you fix Polyfiber?

2:333:44Aerothane Repair on Poly Fiber Fabric - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd we'll push the fabric down into the wet bed a poly tack so that it goes up and saturates.MoreAnd we'll push the fabric down into the wet bed a poly tack so that it goes up and saturates. Through the weave giving us good adhesion of that patch onto the surface over the hole.

What kind of paint is used on aircraft?

There are two main types of paint used on airplanes, enamel and epoxy. Here are the main differences: Epoxy is a polyurethane paint that adheres well to airplane surfaces.

How do you paint fabric wings?

1:1911:33Imitation of fabric on wings - The Great War - YouTubeYouTubeStart of suggested clipEnd of suggested clipTypes. You now it only remains to mix the darker tone of a fabric color and paint it over variousMoreTypes. You now it only remains to mix the darker tone of a fabric color and paint it over various areas do not paint the whole ring with this color you must only spray it along the masking tape.

What is aircraft fabric made of?

Early aircraft used organic materials such as cotton and cellulose nitrate dope; modern fabric-covered designs usually use synthetic materials such as Dacron and butyrate dope for adhesive.

Can I recover my own airplane?

Yes, you can literally build an airplane from scratch if you have the original data plate and a few parts. Obviously, this is the most difficult restoration. It is essentially the same as building an airplane except with more FAA restrictions. Purchase a basket case.

What is Ceconite?

Ceconite is the name of a family of aircraft fabric covering products, all based upon a very special polyester fabric that has become a major industry standard. In a nutshell... It's stronger than Grade A cotton or linen. It's far more durable than either.

How do you repair Ceconite?

To prevent future frustration, cut the patch from very smooth fabric because it's difficult to remove wrinkles. With your patch cut, glue it in place using Ceconite Super Seam fabric cement. The patch's pinked edges give it a greater gluing surface compared to a straight cut.

How do you apply Poly Tak?

Apply the Poly-Tak directly to the model airframe and lay the cloth over the Poly-Tak while it is wet. Work the glue up through the cloth. If the Poly-Tak begins to thicken from evaporation, just thin it with MEK. Don't worry too much about getting the cloth tight when gluing, it can shrink 10 to 12% at 350 degrees F.

How many fabric thicknesses will be found in a French fell seam?

How many fabric thicknesses will be found in a French-fell seam? In a French-fell, machine-sewed seam used to join aircraft fabric, the edges of the fabric are folded over each other so the threads of the double row of stitches passes through four thicknesses of fabric.

What color is the inside of a fuselage?

The color of the inside of the fabric (inside the fuselage) is pinkish gray and will be stamped with square stamps that say either Stits or Poly-Fiber. The paint is not wet-look, high gloss, but rather has a satin finish. when the paint is rubbed with toulene or MEK, it comes off easily.

Do you need to know what fabric is installed on an airplane?

FABRIC REPAIRS: YOU MUST KNOW WHAT'S INSTALLED. Before you repair fabric or touch up damaged paint, you must know what fabric cover ing system is installed on your airplane. If the logbooks are no help, you can easily determine what you have.

Can you touch up paint on an airplane?

TOUCH-UP PAINT Aircraft paint is not interchangeable. If you need to touch up your topcoat paint, make sure you can identify what it is. Once you know the system, ask us for a color card for that system, then hold the card up to your airplane and find the closest matching color.

Is grade A cotton fabric interchangeable?

Grade A cotton is no longer available and your airplane probably has one of the newer polyester fabric systems: Ceconite and Randolph dope, Stits Poly fiber, or either system topcoated with polyurethane paints.These systems are NOT interchangeable.

How to repair fabric?

The method of fabric repair depends on the size of the damaged area. You can repair small areas with a patch, but large tears or rips require sewing the fabric. The Ceconite manual gives the proper fabric repair methods, and it refers to FAA Advisory Circular 43-13-1B, Acceptable Methods, Techniques, and Practices-Aircraft Inspection and Repair, for repairs involving major damage. Major damage is any area more than 16 inches long. It calls areas less than 16 inches casual damage, and you can repair it two ways, with a doped-in patch or a sewn-in patch.

What type of thread do you use for a repair on an aircraft?

You must use Ceconite hand-sewing thread for the repair. Using a 3-inch or 6-inch curved needle will save you time and frustration.

How to remove butyrate from fabric?

Using a clean rag to soak the damaged area with butyrate thinner is another way to remove the butyrate layers. After the thinner has done its work, you can remove the dope with a putty knife or dull blade. Before you soak the dope, carefully mask the area around the damage to keep from removing any more dope than necessary. Using this method is risky because it’s easy to damage the fabric, and you need to take care to not cut the good fabric with the dull blade.

How to sand nitrate dope?

First you’ll sand through the color coats and then through the silver coats. Both of these should be pigmented butyrate dope-one with a color pigment and the other with a silver pigment. Ascertaining when you’ve reached the nitrate dope layers is difficult, so keep sanding until you are just about to bare fabric.

How to remove polyurethane paint?

So, what should you do? Remove the polyurethane paint by peeling it off with a putty knife or by blasting air from an air gun. Sanding is also an option. You can sand down through the paint layers to the underlying coats and then repair the fabric as previously discussed.

What stitch to use for a small tear?

AC 43-13-1B gives the type of stitch you should use. If the damage is a small tear, you’ll be able to sew it closed with a baseball stitch. If you cannot sew the damaged fabric closed, you’ll need to sew in a new section of fabric.

How to cut a dope patch?

After removing the dope, cut your patch out of new fabric after carefully measuring the dope-free area. Use pinking shears and make sure the patch is of the same weight fabric that is on the airplane and that it has the required overlap. To prevent future frustration, cut the patch from very smooth fabric because it’s difficult to remove wrinkles.

How much overlap is needed for polyurethane patch?

It requires only a two-inch fabric overlap and scuffing into the top coat before cementing and refinishing. Other STC repair instructions may not allow this repair

What is the purpose of inspecting a damaged area?

Always inspect a damaged area to ensure the damage is confined to the fabric and does not involve the structure below. A technician who needs to make a fabric repair must first identify which approved data was used to install the covering that needs to be repaired.

How wide is tape needed for AC 43.13-1?

Repair size may also dictate the amount of fabric-to-fabric overlap required when patching and whether finishing tapes are required over the patch. Many STC repair procedures do not require finishing tapes. Some repairs in AC 43.13-1 require the use of tape up to six inches wide .

What is a large section panel repair?

Large section panel repairs use the same proprietary adhesives and techniques and are only found in the instructions for the process used to install the fabric covering. A common technique for replacing any large damaged area is to replace all of the fabric between two adjacent structural members (e.g., two ribs, two longerons, between the forward and rear spars). Note that this is a major repair and carries with it the requirement to file an FAA Form 337.

Can you repair polyester fabric without sewing?

While many cotton fabric repairs involve sewing, nearly all repairs of polyester fabric are made without sewing. It is possible to apply the sewing repair techniques outlined in AC 43.13-1 to polyester fabric, but they were developed primarily for cotton and linen fabrics. STC instructions for repairs to polyester fabric are for cemented repairs which most technicians prefer as they are generally considered easier than sewn repairs. There is no compromise to the strength of the fabric with either method.

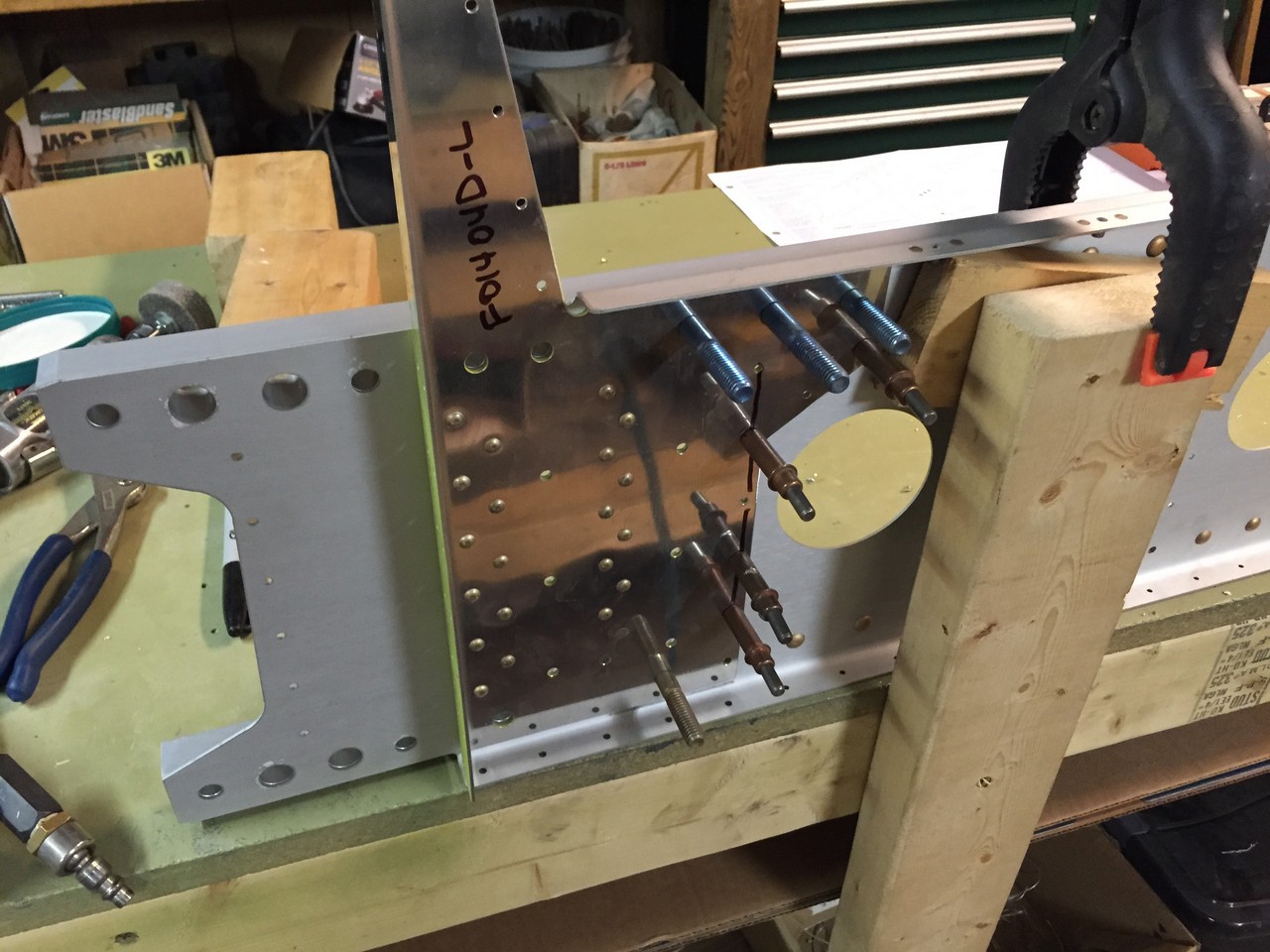

How to repair a lightening hole?

As discussed earlier, lightening holes are cut in rib sections, fuselage frames, and other structural parts to reduce the weight of the part. The holes are flanged to make the web stiffer. Cracks can develop around flanged lightening holes, and these cracks need to be repaired with a repair plate. The damaged area (crack) needs to be stop drilled or the damage must be removed. The repair plate is made of the same material and thickness as the damaged part. Rivets are the same as in surrounding structure and the minimum edge distance is 2 times the diameter and spacing is between four to six times the diameter. Figure 4 illustrates a typical lightening hole repair.

How to repair a panel?

The procedures for making all three types of panel repairs are similar. Trim out the damaged portion to the allowances mentioned in the preceding paragraphs. For relief of stresses at the corners of the trim-out, round them to a minimum radius of ½-inch. Lay out the new rivet row with a transverse pitch of approximately five rivet diameters and stagger the rivets with those put in by the manufacturer. Cut the patch plate from material of the same thickness as the original or the next greater thickness, allowing an edge distance of 21⁄2 rivet diameters. At the corners, strike arcs having the radius equal to the edge distance.

What is stringer repair?

Stringer repair. Extrusions and preformed materials are commonly used to repair angles and insertions or fillers. If repair angles and fillers must be formed from flat sheet stock, use the brake. It may be necessary to use bend allowance and sight lines when making the layout and bends for these formed parts.

What angle to use for stringer repair?

In most cases, a stringer repair requires the use of insert and splice angle . When locating the splice angle on the stringer during repair, be sure to consult the applicable structural repair manual for the repair piece’s position.

What happens to the skin of an aircraft when it is pressurized?

The skin of aircraft that are pressurized during flight is highly stressed . The pressurization cycles apply loads to the skin, and the repairs to this type of structure requires more rivets than a repair to a nonpressurized skin. [Figure 5]

How to install a patch plate?

Chamfer the edges of the patch plate for a 45° angle and form the plate to fit the contour of the original structure. Turn the edges downward slightly so that the edges fit closely. Place the patch plate in its correct position, drill one rivet hole, and temporarily fasten the plate in place with a fastener. Using a hole finder, locate the position of a second hole, drill it, and insert a second fastener. Then, from the back side and through the original holes, locate and drill the remaining holes. Remove the burrs from the rivet holes and apply corrosion protective material to the contacting surfaces before riveting the patch into place.

What is panel in aircraft?

In aircraft construction, a panel is any single sheet of metal covering. A panel section is the part of a panel between adjacent stringers and bulk heads. Where a section of skin is damaged to such an extent that it is impossible to install a standard skin repair, a special type of repair is necessary.

How to secure a patch to an aircraft?

Secure the patch on the aircraft skin and drill pilot holes in the patch. Use the holes previously drilled in the skin as a guide. With the patch still secured to the aircraft skin, expand the holes to the proper diameter. Use clecos to make sure the patch does not move while drilling.

How to make a patch for an airplane?

Cut out a circular patch from a sheet of aluminum that is the same thickness and the original aircraft skin. The diameter will depend on the number of rows of rivets you're planning on installing. Debur the outer edge of the patch. ...

How long does it take to repair a dent in an aircraft?

The time required varies but typically take 1-3 hours depending on skill level and the severity of the damage. The reader should be familiar working with sheet metal and riveting.

Where to center patch on aircraft?

Center the patch over the hole in the aircraft skin and mark its outline.

How to make sure a patch does not move?

With the patch still secured to the aircraft skin, expand the holes to the proper diameter. Use clecos to make sure the patch does not move while drilling. Remove the patch from the aircraft skin and deburr all the holes both on the patch and on the aircraft skin.

What happens when you paint a patch on fabric?

When you paint a stripe of glue onto your painted fabric, the glue dissolves the paint. Then when you quickly try to put the patch on, wiping your finger over the glue stripe, it is almost impossible not to smear the glue and dissolved paint around the edges of the patch.

What happens if you don't use a brush to force polybrush through fibers?

Dan is right. If they didn't use a brush to force the PolyBrush through the fibers, then it will not adhere properly.

Can a heat gun burn thread?

The heat gun will set fire to loose thread. Better to use an iron.

Can you blow out a wing on a heat gun?

It is hard to stop a fabric fire by blowing, but I got it blown out and had to make a larger patch.

What could cause a sag in the fabric of an airplane?

Wrinkles or sags in the fabric most likely point to structural damage. For example, a dent in the metal leading edge of a wing would cause a sag or wrinkle in the fabric that would be visible from the outside.

What material was used to cover airplanes?

The standard material used in the early days was cotton or linen.

How is fabric attached to a wing?

After the fabric is installed and secured to the frame, it’s permanently attached to the wing ribs with a special lacing cord using a designated knot.

What is polyester cloth used for?

Polyester cloth specific to aviation applications is almost exclusively used in the recovering (or initial covering) of an aircraft today . Fiberglass cloth has been used as well, and other synthetic materials have been experimented with and/or are in development.

How to apply dope to fabric?

A plasticized liquid lacquer (i.e., dope) is applied to the fabric in several applications initially by brush and then by spray gun to form an airtight and waterproof bond that also tightens and stiffens the fabric materials.

How to tell if a paint job is failing?

Check for cracked and missing paint or dope that would allow sunlight to directly access the fabric. Look for ringworm in the fabric; this indicates that the paint job is failing and will cause the cloth to deteriorate in a short time if exposed to direct sunlight.

Why are synthetic materials used in fire?

Synthetic materials and associated application processes not only reduce the amount of labor required, but also provide longer life, resistance to rot and fungus, and are safer in the case of fire (during material application, and while in flight).