- Cut two fiberglass patches 6 inches (15 cm) larger than the hole. ...

- Mix even amounts of each part of the epoxy in a bucket. ...

- Spread a thin layer of epoxy on one side of the hole with a putty knife. Cover the entire area surrounding the hole with a layer of epoxy.

- Press one of the fiberglass patches onto the epoxy, so that the hole is in the center. ...

- Paint another layer of the epoxy over the fiberglass. This time as you apply the epoxy, spread it over the part of the mesh that covers the hole.

- Let the epoxy dry for 24 hours. Let the epoxy set on one side of the plastic before transporting the plastic or moving on.

- Repeat the process on the other side of the hole. ...

- Sand the epoxy until it is smooth. Once both sides of the epoxy are set and dry, you can use sandpaper to smooth any dry epoxy, so it is ...

How to clean plexiglass quickly and easily?

Tips for Cleaning Plexiglass and Acrylic

- Easy Cleaning Process. Before you begin cleaning your acrylic or plexiglass panel of fingerprints, dust, and dirt, clear the surrounding area of any objects that may obstruct your working space.

- Sanitizing Acrylic and Plexiglass Panels to Protect Against COVID-19. ...

- Advanced Cleaning & Repairing Plexiglass. ...

- If All Else Fails... ...

How to fix broken plexiglass?

- Disposable plastic strips

- Staple or wire

- Instant glue, soldering arms or other way to keep parts in place that you are welding

What glue is best for plexiglass?

You have to follow step by step:

- Select a strong workspace

- Clean the Plexiglas

- Put the acrylic glass in place to glue

- Apply the glue to the joint

- Let the bond stay for firm adhesion

- Sand joints smooth

- Check joints to make sure they are watertight

How to cut plexiglass without chipping?

- Leave the protective film on its surface while cutting, as long as possible.

- You may need to smoothen the edges. Because cutting may produce very rough edges.

- Score deeply to prevent it from breaking on unexpected position.

- Use the right blade if cutting plexiglass with a power saw (e.g. miter saw ). ...

- Keep the blade cool. ...

How do you fix a hole in plexiglass?

6:057:59Arcade Repair Tips - Drilling Holes In Plexiglass - YouTubeYouTubeStart of suggested clipEnd of suggested clipThat you do not start off with the bigger bit that is probably about the size of the screw you needMoreThat you do not start off with the bigger bit that is probably about the size of the screw you need start off with a small pilot hole. So you can actually start here.

Can you melt holes in plexiglass?

Using a normal battery or electric drill, run the drill in REVERSE at the highest speed possible with a normal drill bit. Apply firm pressure as you push the bit through the acrylic. This will melt the plastic rather than chip it. It takes a little longer, but will give you perfect holes without cracking.

How do you fill acrylic holes?

A makeshift cement from super glue and baking soda can fill small holes in a pinch. Larger holes in plastic can be filled with melted plastic or epoxy.

How do you put a hole in plexiglass without cracking them?

1:395:42How To Drill Acrylic And Other Brittle Plastics - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd this helps even with ordinary drill bits is to use dish soap as a lubricant.MoreAnd this helps even with ordinary drill bits is to use dish soap as a lubricant.

What is the difference between acrylic and plexiglass?

The biggest difference between Plexiglas® and some traditional acrylic is the way they are manufactured. Acrylic can be manufactured one of two ways: extruded or cell cast. Plexiglas®, however, is manufactured in cell cast only. That is the biggest benefit to purchasing Plexiglas® over other brands of acrylic sheeting.

Is acrylic a plexiglass?

We can give a short answer to this: there is absolutely no difference. This is because acrylic is the usual abbreviation for polymethyl methacrylate, and Plexiglas® is one of the many brand names of this plastic. Over time this brand name has become generic as 'plexiglass'.

Can you use a drill bit on plexiglass?

0:233:11How to easily drill plexiglass, lexan and acrylic sheets - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd all you really have to do is clamp the plexi vilette's and down to a backrub or a piece of scrapMoreAnd all you really have to do is clamp the plexi vilette's and down to a backrub or a piece of scrap wood. Slow down the drill. And use very little pressure.

How do you fix a small hole in a plastic bumper?

Answer provided bySand the area around the hole to ensure a smooth surface.Affix a piece of repair adhesive to the inside of the bumper.Apply adhesives to the exterior of the bumper, following the manufacturer's instructions.When dry, sand smooth and paint over the area.

How do you spackle holes?

0:453:04How to fill and spackle holes in drywall. Fixing a hole in sheet rock ...YouTubeStart of suggested clipEnd of suggested clipInto your exterior spackle. And press it in so it fills up that hole. Take our whines back and.MoreInto your exterior spackle. And press it in so it fills up that hole. Take our whines back and. Right. Once that holds level in smooth.

What type of bit should be used to drill holes in plexiglass?

Spade drill bit and Forstner drill bit 400 characters): Spade drill bits and Forstner drill bits, normally used for drilling wood, are also suitable for drilling acrylic sheets. When using bits of this kind, take care that the bits do not transport shavings out of the drill hole.

Can you drill acrylic plastic?

You can drill acrylic with a normal steel drill or an HSS drill. It is important that the drill is not brand new, as the sharp cutting angle can cause the drill to bite into the sheet, causing it to tear.

Can I use a soldering iron to make holes in plastic?

Even a cheap soldering iron will reach temperatures in excess of what is needed to heat plastic. In a well ventilated area, turn on the soldering iron and allow it to heat up. Then with only a light pressure, press the tip of the iron at the desired location, and it will melt a drain hole through the plastic.

What type of bit should be used to drill holes in plexiglass?

Spade drill bit and Forstner drill bit 400 characters): Spade drill bits and Forstner drill bits, normally used for drilling wood, are also suitable for drilling acrylic sheets. When using bits of this kind, take care that the bits do not transport shavings out of the drill hole.

Does acrylic crack when drilled?

Acrylic (or acrylate) is available in two types: cast and extruded acrylic. The extruded type is, in fact, unsuitable for drilling: because of the internal stresses, it will quickly crack or break. Drilling it is not impossible, but great caution is required.

How do you make a hole in plastic without cracking it?

0:091:12Without Splitting it. Putting holes in plastic container. - YouTubeYouTubeStart of suggested clipEnd of suggested clipThe best way to prevent splitting or cracking is to push a hot rod or pipe through the plastic byMoreThe best way to prevent splitting or cracking is to push a hot rod or pipe through the plastic by melting.

How do you drill a 2 inch hole in plexiglass?

0:053:13HOW TO: Drill Acrylic - YouTubeYouTubeStart of suggested clipEnd of suggested clipI'm going to be using a hole saw to drill the hole what this will do is drill a large hole directlyMoreI'm going to be using a hole saw to drill the hole what this will do is drill a large hole directly in the acrylic.

Step by Step Guide to Drill Holes in Plexiglass

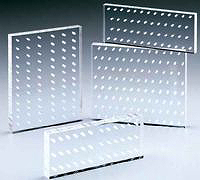

Plexiglass is a worthy alternative to glass that is also known as acrylic, thermoplastic, and Lucite. This shatter-resistant polymer is frequently used in construction projects that demand lightweight yet durable plastic. But the plexiglass is a brittle material that can scratch and creak easily, thus requiring adequate care.

Types of Drill Bits for Plexiglass

Plastic Drill Bits: The plastic drill bit is mainly used to create a hole in the plastic. This drill bit is designed with ground flukes with a 0-degree rake and 90-degree points. It can also shave plexiglass away layer by layer. Plastic drill bits come in a range of diameters and are available in both local stores and online.

FAQs on How to Drill Holes in Plexiglass

Using a rotary tool’s cutting disk, you can easily create slots on the edges of plexiglass. But you have to pay more attention while cutting the slot in the edge as the cutting disk can kick back and bind up during the operation.

Why is the left part of the crack more visible after gluing?

The LEFT most part of the crack is more visible after gluing because I had to score the acrylic in order to start a crack in it for the demonstration .

How long does it take for Johnacrylic glue to dry?

johnacrylic. One thing I forgot to mention is to allow the glue to dry for a couple hours. It sets up quick but needs time to build up strength. Do not move or even touch the piece you are gluing during this time.

How to fill tiny holes in plastic?

Start by attaching a piece of scrap cardboard to the backside of the hole to keep material from dripping through. Add some super glue over the hole and then sprinkle a pinch of baking soda on top of the glue.

How to put fiberglass in epoxy?

Press one of the fiberglass patches onto the epoxy, so that the hole is in the center. Use your hands to push the fiberglass the hole is in the middle of the patch. The excess fiberglass on each side ensures there is enough to cover the hole and will add a smooth transition between the plastic and epoxy.

How to make super glue thicker?

Sprinkle a pinch of baking soda on top of the glue and press firmly. Press the baking soda into the super glue with your finger or a flat edge, so the two substances bond together. Super glue is thin, but when combined with a powder like baking soda, it thickens and makes more of a cement-like substance.

How to make a pool with super glue?

Make a small pool at the bottom of the hole with a few drops of super glue. The backing will give the glue a flush edge at the bottom of the hole. Super glue dries quickly, so you will have to work fast before it sets. Wear plastic gloves to avoid getting super glue stuck on your hands.

How long does epoxy cure on fiberglass?

Paint another layer of the epoxy over the fiberglass and let it cure for another 24 hours.

How long does it take for plastic to solidify?

Let the plastic cool for five minutes before filing it. It only takes a few minutes for the plastic to solidify. Once it is cool to the touch, use a file or sandpaper to smooth out plastic and make it flush. If you want to get rid of any file markings, hold the plastic welder just above the area to smooth it out.

How long does epoxy take to dry?

Let the epoxy dry for 24 hours. Let the epoxy set on one side of the plastic before transporting the plastic or moving on. As it dries, it will harden and form a solid layer. It takes at least 24 hours for the epoxy to initially cure, though it may take longer in humid climates.

How to join plastic pieces together?

Gather materials. Get together all the plastic pieces you want to join. You’ll also need and your adhesive, of course, tissue paper, something to protect your work area, and sandpaper (for bonding smooth surfaces). Stay safe. Work in a well-ventilated, protected area.

How to remove uncured adhesive?

If you need to clean up larger quantities of uncured adhesive, moisten it and let it cure before carefully scraping it off. You can cut away cured adhesive with a sharp blade and remove it with acetone or boiling water.

What adhesives can be used to bond plastic?

Some products are better suited for large projects, while others can bond only certain kinds of plastic. Some adhesives, such as Loctite Plastic s Bonding System, are formulated to bond difficult materials like polyethylene, polypropylene, and Teflon.