Using Other Methods to Fix Loose Holes

- Plug holes with golf tees if the holes are big enough. Remove the loose screws and the hinge. Dip the tip of a golf...

- Fill holes with toothpicks or matches to provide added grip for screws. Unscrew the loose screws and remove the hinge...

- Put wood anchors into stripped holes so the screws fit tightly. Buy some plastic,...

How to fix a loose wood screw?

Steps Download Article

- Remove the screw.

- Insert a round or square tooth-pick all the way into the hole.

- Bend the tooth-pick to mark the required length (don't break it yet).

- Pull the tooth-pick out and now break it at the bend.

- Replace the tooth-pick in the hole with the pointed end facing out.

- Replace the screw and it should tighten up as if it was a new hole.

How to stop screws from loosening?

Method 1 Method 1 of 3: Installing New Screws Download Article

- Use longer screws if the old ones pull out from the holes. Shorter screws can’t dig into material very well since they don’t have a lot of threadings.

- Try screws with a thicker diameter when the holes are too wide. ...

- Slide a flat washer and spring washer on the screw to absorb vibrations. ...

How to remove a stripped or broken screw?

Method 2 Method 2 of 2: Taking out a Screw with a Stripped Head

- Use a different size screwdriver to see if it catches as an easy fix. ...

- Place a rubber band over the screw to increase the grip of the screwdriver. ...

- Pour chemicals on rusted screws to help release them. ...

- Glue the screwdriver or bit to the screw head for screws that won't catch. ...

How to fix stripped screw holes?

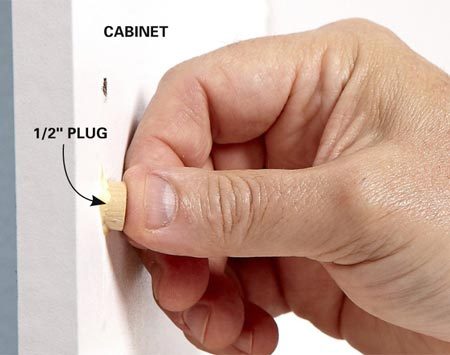

- Prepare the damaged hole

- Look for the right size of the Helicoil insert

- Drill out the old screw hole

- Thread it with a tap set

- Install the Helicoil insert

- Remove the tang

How do you make a screw tighter in a hole?

0:391:43How to tighten a screw when the pilot hole is too big. - YouTubeYouTubeStart of suggested clipEnd of suggested clipJust cut the edge.MoreJust cut the edge.

How do you fix a stripped screw hole in the wall?

The best way to reuse a stripped screw hole in drywall is to insert a snug-fitting drywall anchor, then drive a screw into the anchor. If the hole is too large for a drywall anchor to fit tightly, insert a toggle bolt to create a far more secure and durable way to hang items on drywall.

How do you fix an oversized screw hole?

First, fill the hole with any liquid glue that can be used on wood, such as Elmer's Wood Glue. Note that the glue is helpful, but not always necessary. Second, jam in several wood toothpicks or matchsticks until they snugly fill the hole.

How do you fix a drywall screw hole?

Tiny nail and screw holes are the easiest to fix. Use a putty knife to fill them with spackling or wall joint compound. Allow the area to dry, then sand lightly. Anything larger must be covered with a bridging material for strength before patching compound can be applied.

How do you fix a screw hole in drywall for reuse?

If the screw hole you wish to reuse was originally just a screw driven into drywall, you might be able to make it strong enough for reuse by adding a drywall anchor. Use a hammer to tap a plastic drywall anchor into the hole gently. If it fits snugly, it's the perfect solution.

Can I screw into wood filler?

Yes, you can drill and screw into epoxy-based wood fillers when dry. However, it is often essential to drill a hole into a wood filler before dragging a screw into it. Screwing directly into an epoxy can cause it to crack since epoxies are generally very dense.

How do you fix a big screw hole in wood?

0:446:22How to Fix Stripped Screw Holes - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd get some toothpicks for this hole right here three ought to do it just place them in the hole.MoreAnd get some toothpicks for this hole right here three ought to do it just place them in the hole. Like that break off the excess.

How do you make a metal screw tighter?

Tighten a loose set screw by wrapping sewing thread around the screw threads and then installing the screw back into the screw hole. Screws that join pieces of metal can become loose over time, especially if the joint is under any kind of constant movement or stress.

What do you do with a stripped screw head?

Use an Abrasive Powder Similar to the steel wool method, the more friction you can apply to the head of the screw, the better. You can sprinkle a small amount of abrasive cleaning powder or fine sand on the surface of the stripped screw, then apply the drill driver-bit to the screw and try to turn it out.

Can you screw into wood filler?

Yes, you can drill and screw into epoxy-based wood fillers when dry. However, it is often essential to drill a hole into a wood filler before dragging a screw into it. Screwing directly into an epoxy can cause it to crack since epoxies are generally very dense.

How many holes can an anchor repair?

A single anchor can repair three to four stripped holes and work with softwoods, hardwoods, plywood, MDF, particle board. It is so versatile that you won’t need to remove the door or hinge to repair stripped holes in your frame or cabinet. It can be driven with a simple screwdriver.

What is a wood screw used for?

which have interlocking joints. The wood screw is used as a replacement of less strong glues or simple nails as a part of the mechanical connection between the joints which is hard-wrought.

How to stop a drill from wandering?

We recommend you to use a doweling jig to prevent your drill from wandering. After that, you have to fill the hole with a piece of dowel and plenty of glue and tap it down into exact place. Now you can go ahead and reassemble the joint. Make sure you drilled a new pilot hole for the screw.

Can screws be threaded into particle board?

It’s also a very common problem when screws are threaded into composite materials like particle board which isn’t very strong stuff, to begin with. In those situations, we are going to show you three simple options or ways to fix or repair the loose screws that just won’t tighten up well.

Can particle board hold screws?

If you ever worked with p article board then you probably know that it doesn’t hold screws very well. The threads can crumble easily in this kind of soft material if you overdrive the screw.

Can you use loose screws on a passage door?

The first one is a pretty common example which is loose screws on the hinges of a passage door. This particular door happens to be made out of a material which doesn’t have a grain structure to it. So anyway it doesn’t hold screws very well besides this hinge screws are very short. Hinge screws are too short to hold very well which makes the effort of fixing loose screws less easy. But the door has a wide style in it which can definitely accept longer screws.

How to fix a hole in a golf tee?

Plug holes with golf tees if the holes are big enough. Remove the loose screws and the hinge. Dip the tip of a golf tee into carpenter’s glue, tap it into a loose hole using a hammer, then snap off the excess wood sticking out of the hole. Reattach the hinge by driving screws through its holes into the golf tees after the glue is dry.

How to unscrew a hinge plate?

Remove the loose screws and the hinge plate with a drill or screwdriver. Use a screwdriver or electric drill to unscrew the loose screws all the way. Set the screws aside and swing the hinge plate away so it’s not covering the loose holes.

How to make a dowel with carpenter's glue?

Coat a 1 in (2.5 cm) long, 3⁄8 in (0.95 cm) diameter dowel in carpenter’s glue. Squeeze a drop of carpenter’s glue out onto the side of the piece of wooden dowel. Use your fingers or a scrap piece of dowel to spread the carpenter’s glue up and down the sides.

What glue holds dowels in place?

The carpenter’s glue will hold the dowel in place inside a stripped hole.

How to hold wooden dowels steady?

If you use a handheld saw, clamp the wooden dowel to a workbench or put it in a vise to hold it steady while you cut the pieces.

How to cut a 3/8" dowel?

Measure and mark 1 in (2.5 cm) long sections along an entire piece of dowel. Use a hand saw or any type of power saw you have available to cut the pieces.

How to get rid of a hole in a wood dowel?

Tap the wooden dowel into 1 of the holes gently using a hammer. Push 1 end of the piece of wooden dowel into 1 of the stripped holes. Carefully tap it in with a hammer until it is flush with the surrounding wood.

How many times has wikihow been viewed?

To create this article, volunteer authors worked to edit and improve it over time. This article has been viewed 39,153 times.

What is wikihow wiki?

X. wikiHow is a “wiki,” similar to Wikipedia, which means that many of our articles are co-written by multiple authors. To create this article, volunteer authors worked to edit and improve it over time. This article has been viewed 39,153 times.

How to replace toothpick in a hole?

Replace the tooth-pick in the hole with the pointed end facing out.

How to mark the required length of a toothpick?

Bend the tooth-pick to mark the required length (don't break it yet).

How to replace a screw in a hole?

Remove the screw. Insert a round or square tooth-pick all the way into the hole. Bend the tooth-pick to mark the required length (don't break it yet). Pull the tooth-pick out and now break it at the bend. Replace the tooth-pick in the hole with the pointed end facing out.

What to use for a hole in a wood table?

If you have no tooth-pick, use a sliver of wood that fills less than half of the hole. In a pinch, soft plastic will do.

How to repair a hole in wood?

You simply need to make the hole smaller so the screw can grip the wood. It's very easy to repair a hole with a tooth-pick. You only need: a screwdriver and toothpicks.

Where do screws lose their hold?

The hinges on cabinet doors, entry doors, chest lids, and other such places receive lots of wear and tear. An entry door , for example, has hinges that are stressed thousands of times, and it is quite common for the screws holding these hinges to lose their hold with time.

Why do screws stop holding?

When screws stop holding within a wood joint, it is usually because the wood fibers around the screw threads have torn away for some reason. Screwed joints get their strength because of the way the threads wedge themselves into the wood fibers, and if wear-and-tear or sudden stress on the joint causes those wood fibers to tear free, ...

How long does it take for glue to cure?

Let the glue cure fully (about 24 hours), then drill a pilot hole in the center of the plug and drive the screw into the pilot hole. If the damaged area is badly broken, try gluing it back together before using the plug trick. Using Wood Screws in Your Woodworking Projects. Read More.

Why is wood tearing out?

Wood can also be torn out if a joint is suddenly put under greater pressure than the wood fibers can tolerate—such as when cabinet or drawer with screwed joints is dropped on a hard surface. Here are five different solutions you can try when screws loosen or tear free of the wood they are supposed to be holding.

Can you strip wood when you install it?

It is also possible to strip the wood if you drive a screw with too much force when you install it. If wood screws are overtightened, the threads can tear out the wood rather than wedge themselves between the fibers. Wood can also be torn out if a joint is suddenly put under greater pressure than the wood fibers can tolerate—such as ...

Can you cut filler strips from the same wood?

It's best to cut the filler strips from the same type of wood because it will look and behave the same as the original wood. If you use hardwood filler strip in a softwood piece, for example, the hardwood might split the softwood as it expands when the screw is driven in.

How to fill oversized screw holes?

7) Another method of filling oversized screw holes is by using golf tees. Tap the tee into the hole and mark where it needs to be cut to become flush with the edge of the surface. Remove the tee and cut slightly below the mark so that it will be flush or even slightly sunken.

How to make a pilot hole in toilet tissue?

Take two or three sheets of toilet tissue and mix with 20ml (approximately a tablespoon) of multi-purpose glue, the tissue will disintegrate within no time at all and easily mix together with the glue creating a white clay like filler. Push the filler into the screw hole and take a small nail or wood pin to make a pilot hole.

How to thread a ratchet?

If you’re using a ratcheting tap handle, slowly work the tap into the hole about a half of a turn, back it up a quarter turn, and then repeat until you’ve reached the bottom of the pilot hole. This ensures clean-cut threads and keeps shavings from interfering.

How to install helicoil in a tap?

Once the tap is inserted, install the Helicoil insert into the tap. Use the insert tool to put the Helicoil insert as far into the tap as you need it. Once you have the insert in far enough, remove the installation tool, leaving the Helicoil insert.

How to remove a tang from a helicoil?

Break off the tang of the Helicoil insert at the notched portion of the tang on the insert. Use an insert to break off the tang and tweezers or magnet to retrieve the tang that you broke off. For all Helicoil inserts, the tang must be removed.

Do You Need to Clean and Lubricate the Hole?

Yes, it is important to properly clean and oil/lubricate the hole when you’re drilling and tapping. This helps to ensure a nice, clean hole and keeps small metal shavings from interfering with the new threads. Also, the lubricant helps to provide a smooth, easier cut.

What do you need for a 1309 dowel jig kit?

Milescraft 1309 DowelJigKit. All you need for doweling in one kit. Includes dowels of three different sizes, a dowel jig, centers, drill bits, and wood glue. First, drill out the hole with a drill bit that is the exact diameter as or a pinch smaller than the wooden dowel you are planning to use.

How to fix a hole that is too big?

Finally, drill a small pilot hole into the fixed spot to guide the screw. Using a golf tee: If you have a spare golf tee lying around, it can be useful in fixing a hole that’s too large. First, tap the tee into the hole and mark where it needs to be cut to become flush with the edge, then remove it and cut it to fit.

How to fill a hole in a wood table?

First, fill the hole with any liquid glue that can be used on wood, such as Elmer’s Wood Glue. Note that the glue is helpful, but not always necessary. Second, jam in several wood toothpicks or matchsticks until they snugly fill the hole.

What is a rawl plug?

You’ve probably seen a rawl plug – it’s a generally plastic insert that is used to provide grips for screw being driven into concrete walls among other materials. You can also use it if you mistakenly drill too big of a hole into wood or other material.

How to make a shim out of pinewood?

Using a pinewood shim: For this method, you’ll need some pinewood and a sharp knife to trim it with. Trim the pinewood into a pointed shape, then coat it with wood glue and insert it into the hole. Wait for the glue to dry, then use a chisel or a sharp knife to cut the pine until flush with the wood.

What is the best way to widen a hole in a screw?

Depending on the specific situation, a toggle bolt might be the best choice. In case the hole needs to be expanded a bit to accommodate the larger screw or anchor, it can be widened slightly using an appropriately sized drill bit. If using a longer screw, make sure it’s not too long or it may pop out of the other side.

How to use steel wool to make screws tighter?

Using steel wool: A method that will only work for light loads. Tightly pack steel wool into the hole using a screwdriver or a similar tool. The compacted steel wool will provide the screw with a tighter grip. Using a pinewood shim: For this method, you’ll need some pinewood and a sharp knife to trim it with.