How To Re-Solder A Copper Pipe Joint Without Removing It

- Drain The Water. Be sure to completely shut off the water at the main valve in your home. ...

- Dry And Sand. You will want to dry the outside of the elbow thoroughly. ...

- Apply Flux. Apply soldering flux around the entire joint. This is essential because it helps to prepare the copper for soldering.

- Heating To Replace The Old Solder. This next step is the fun part, and it involves your soldering torch. ...

- Wait. You must let the pipe cool for at least five minutes. Do not attempt to push this any faster than that.

- See If It Worked. Finally, you can turn the water back on. Let’s hope that your solder worked and that you stopped the leak!

- The Trick. Replace the elbow with a tee with a threaded fitting soldered on one end. The open end can allow moisture to escape.

Is soldering bad for You?

Therefore, solder that contains lead is considered to be toxic. In addition, using flux containing rosin (also called colophony) produces solder fumes that, if inhaled, can result in occupational asthma or make existing asthmatic conditions worsen. The fumes can also cause eye and upper respiratory tract irritation. Click to see full answer.

How to solder for beginners?

Tips for successful and safe soldering for beginners

- Soldering is a high-temperature task. ...

- Use pliers to hold parts of the soldering to avoid burning. ...

- Unless you are purchasing a soldering iron for plumbing, always think fine tips when buying soldering irons to work on PCBs.

- As a beginner, it is always advisable to try out and refine your soldering skills on an old board before working on a good one.

What is the proper way to solder?

- Use the lowest wattage soldering iron possible so you do not overheat the pcb or components.

- clean the pcb and component leads

- Use proper flux (not acid flux)

- use proper solder

- heat the joint first

- ** Touch the solder to the heated joint - NOT to the soldering iron

- let the solder flow into the joint

How to properly solder?

With proper soldering of wires, the following operations must be performed:

- Cut the wires to the required length.

- Remove the plastic (woven) insulation with a knife or special tool to the specified length.

- Sand the bare ends with an emery cloth (knife).

- Tape the ends with flux Alpha lead free solder wire.

Can you solder over old solder?

Just heat the joint up with your torch, once the solder starts to melt use Channel locks to pull the fittings apart. Once the joint is apart, wipe as much old solder off as you can with a rag. Now you can start over. Clean, Flux, solder.

Can you remelt solder?

Try putting some fresh solder on the tip of the iron and see if that helps. Your new ground can be connected anywhere on the back of the pot. You could even just clip the old wire and put the new one next to it if you're unable to get all of that solder off.

How do you fix a pinhole in a solder joint?

0:442:03Can You Temporarily PATCH a Pinhole With Solder? | GOT2LEARNYouTubeStart of suggested clipEnd of suggested clipJust enough so your starter will melt. The trick here is to use your torch to heat the pipe up atMoreJust enough so your starter will melt. The trick here is to use your torch to heat the pipe up at the right temperature to do this keep it closed in the beginning.

Can you Resolder leaking joint?

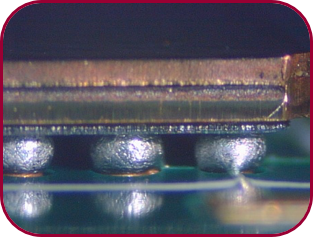

Dry the outside of the elbow and sand (120-grit paper or cloth) around the leaking joint to remove all surface corrosion. Apply soldering flux around the whole joint and apply heat with a torch until the old solder melts. Add new solder until a shiny ring of solder shows all around the joint.

Can solder be reused?

0:594:47( Electronics ) Can you reuse old solder? - YouTubeYouTubeStart of suggested clipEnd of suggested clipIf you're going to be reusing solder flux is a must usually when you buy new solder and it comes inMoreIf you're going to be reusing solder flux is a must usually when you buy new solder and it comes in a reel.

How do you fix a pinhole leak?

2:354:53How to fix a pinhole leak in copper pipe. - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd try and line that rubber up with the center of the rubber. So the rubber in the pinhole. BothMoreAnd try and line that rubber up with the center of the rubber. So the rubber in the pinhole. Both centered and then I'm simply just gonna tighten that hose clamp up with my nut driver.

How do you temporarily fix a pinhole leak in a copper pipe?

1:217:03How to Fix an EMERGENCY LEAK: Two Methods - YouTubeYouTubeStart of suggested clipEnd of suggested clipOff we're going to take our rubber gasket. Place it over the pinhole. Leak. Put the hose clamp on itMoreOff we're going to take our rubber gasket. Place it over the pinhole. Leak. Put the hose clamp on it. And then we're going to finish tightening it the rest of the.

Can you solder with water in the line?

Don't try to solder pipes with water in them. When you're repairing or tying in to existing copper pipes, it's common to find a small amount of water in them even after you close the valve and drain the pipes. Soldering a joint in pipes that contain even tiny amounts of water is nearly impossible.

How do you melt stubborn solder?

0:556:49How to Desolder Through-Hole Parts, Why Some Joints are DifficultYouTubeStart of suggested clipEnd of suggested clipContact. Now hold the wick over the joint and gently press the iron on top of it. Continue holdingMoreContact. Now hold the wick over the joint and gently press the iron on top of it. Continue holding the wick on the joint for several seconds to make sure all the solder is removed.

Does flux remove solder?

Its purpose is to remove oxides and impurities from the board. Using flux improves the solidity of the soldering joints. The main downside to the use of flux is that it leaves residues on the boards. It is essential to remove these residues after soldering.

Can you desolder with a soldering iron?

Soldering iron is the simplest and easiest method to desolder components. You do not need any other tools apart from the soldering iron and a pair of fliers. Here is what you have to do, Heat the solder using the soldering iron until it starts to melt.

Do I need flux to desolder?

You will need to add your own flux as you desolder. Unfluxed wick has a part number that starts with 1830 through 1833.

What is excess solder?

What It Is:#N#Excess solder that unintentionally links two or more connections together is called a “bridge”. This defect is very likely to cause erratic functionality and physical damage to the assembly.

What is the N# during the surface mount reflow phase of assembly?

What It Is:#N#During the surface mount reflow phase of assembly, the solder may fail to flow onto both sides of a surface-mount chip. This defect leaves one side of the chip suspended above the solder pad rather than connected to it.

Can you save circuit boards?

Faulty circuitry can’t always be avoided, but it can often be rescued. By knowing which solder joints your trusty soldering iron can handle, you may just be able to save the board right away. And, knowing when to send the struggle to the professionals may just save you the entire board altogether.

What does it mean when a solder joint is broken?

A broken solder joint is where the solder connecting the component pin or leg to the copper track on the circuit boards becomes damaged. Bad contact with the copper track of course means a poor connection (intermittent problems) or no contact at all (device stops working altogether).

What is a cracked solder joint called?

A cracked, fractured or broken solder joint is sometimes (erroneously) called a ‘cold’ or ‘dry’ joint (but both those terms relate to problems with soldered joints from the start). Calling it a ‘broken solder joint’ works for me, and is a better description for this very common electronic failure problem.

Why does solder crack?

Broken solder joints are often caused by…. Excess heat, where the pins/legs and the solder surrounding them expand and contract at different rates in use eventually causing cracking and erosion of the solder. Fatigue, where the connection between the component pin/leg and the copper track cracks due to repeated movement or flexing.

Can you solder without flux?

First, always use a proper when soldering (and not one designed for copper plumbing pipework). This magical paste will chemically clean the joint making the solder ‘stick’ much better. In fact, soldering without flux is virtually impossible (trust me on this, I know!).

How much solder should I use for a pipe joint?

Not so much with larger piping, but with 1/2" it is easy to do it. You should only use about 1/2" to 3/4" of solder to make a joint on that size; don't add more or you could just fill the pipe.

Why won't my solder work?

Since you have leaking joints, heating them up and adding more solder will not work because the new solder won’t get sucked into the joint due to a lack of flux. Sorry to say, each bad joint will have to be removed. I would use a MAPP gas torch, as it burns hotter than propane, which will get the job done quicker.

Do you need a gas torch for copper pipe?

Don't need a MAP gas torch. Propane is plenty hot for normal sized copper piping (up to 3" or so). Wiping a rag on the fitting isn't needed, all that does is smear the solder that's hanging on the outside of the fitting around. Looks better, but it doesn't do anything else. Don't use too much flux.

Should you apply flux to joints?

You should not be applying flux to joints you are not working on, take each joint one at a time. If the joints are all close to each other, try doing the joints out of order. Solder one joint, then move to a joint further away, then back to a joint near the first, etc.