Welding Thread Repair Method

- Clean the area thoroughly using solvent to help minimize the possibility of contaminating the weld.

- Weld-up the existing hole. ...

- Drill the new hole so that its axis is perpendicular with the originating surface. ...

- Cut new threads in the hole by thread milling or using a tap.

- Drill thread. First you drill the damaged thread with a twist drill. ...

- Cut thread. Now you can cut the new thread with the single-cut tap. ...

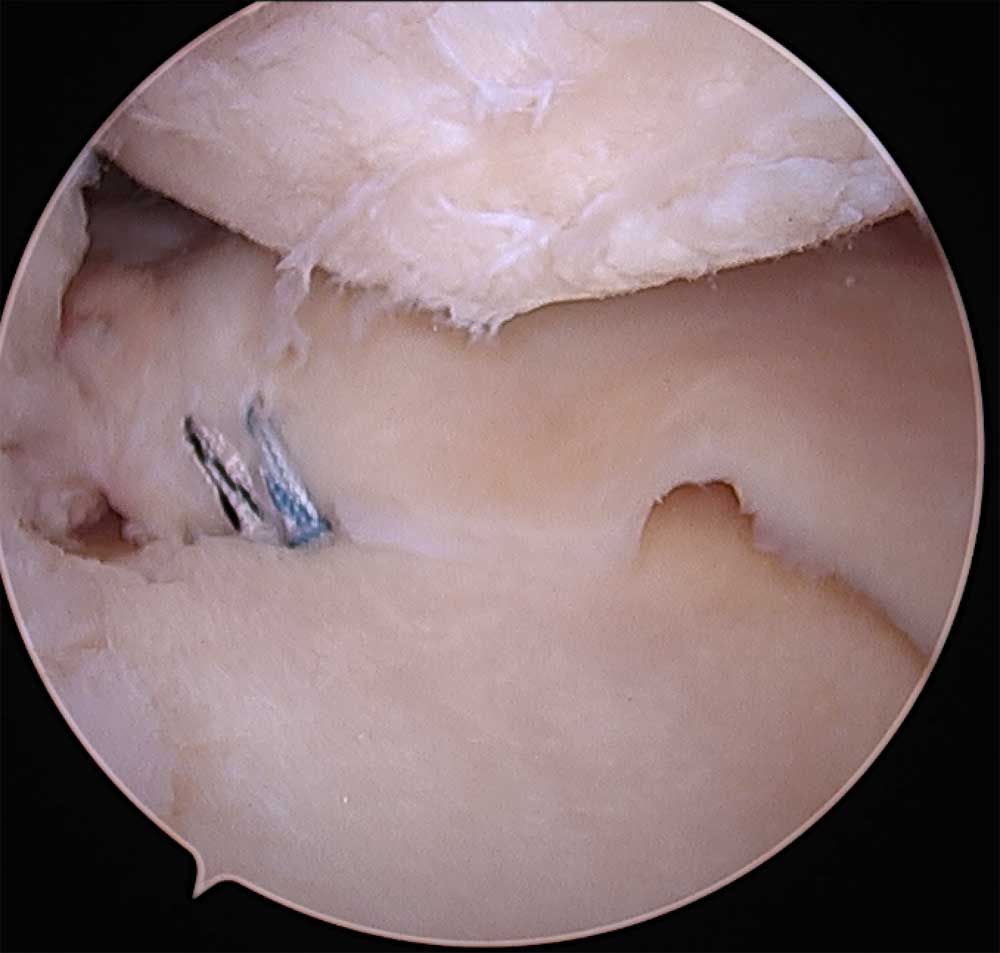

- Insert thread insert. Put the thread insert on the fitting-tool or directly into the hole (see second picture below). ...

- Break pin.

What tool is used to cut threads inside a hole?

+ How to tap a hole.

- Identify the thread and tap you require. This step sounds easy but it often gets done incorrectly especially when repairing a thread. ...

- Load the tap into the wrench. Typical tap wrenches have a square cut out for the rear of the tap. ...

- Lubricate the hole. ...

- Align the tap straight with the hole. ...

- Cut the thread. ...

- Remove the tap and flush with air or fluid. ...

How to easily fix screw holes in a drywall?

Instructions

- Inspect and Trim the Face Paper. If any of the face paper on drywall puckers outward, this needs to be trimmed before you cover the holes with joint compound.

- Load the Drywall Knife. ...

- Apply the First Pass. ...

- Apply a Second Coat. ...

- Lightly Sand (If Necessary) Once the second coat is fully dry, run your hand over the patched area. ...

How to get rid of loose threads?

- Sewing needle

- Scissors

- Thread (matched to the color of your fabric)

- Thimble (optional, for those who like a little extra protection)

How do you fix Dart holes in the walls?

Method 2 of 2: Patching with a New Piece of Drywall Download Article

- Cut the hole into a neat square or rectangle. Home Improvement Specialist Expert Interview. ...

- Create a patch out of drywall that is 2 in (5.1 cm) taller than the hole. ...

- Put a screw through the middle of the patch to make a handle. ...

- Apply construction adhesive to the bottom and top edges of the patch. ...

How do you fix a stripped thread hole?

2:168:36How To Fix a Stripped Out Bolt Hole - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo it's really easy to cross thread one in there and tear the threads up and then you go to cinch itMoreSo it's really easy to cross thread one in there and tear the threads up and then you go to cinch it down and you just pull the rest of the threads out.

How do you fix a threaded metal hole?

0:009:51FIX stripped bolt hole threads the POOR MANS WAY - YouTubeYouTubeStart of suggested clipEnd of suggested clipToday we're gonna see if we can repair strip threads with j-b weld. Let's find it out keep watching.MoreToday we're gonna see if we can repair strip threads with j-b weld. Let's find it out keep watching. So here we got a piece of cast aluminum that I have intentionally stripped out some threads.

How do you repair threads?

1:555:40Thread Repairs - YouTubeYouTubeStart of suggested clipEnd of suggested clipWhen we strip the threads out of the inside of a hole things can get a little more complicated.MoreWhen we strip the threads out of the inside of a hole things can get a little more complicated. Sometimes you can just drill the stripped hole out and thread it for a larger fastener.

Can you fix a threaded screw?

Damaged threads on a screw or bolt can often be fixed by running a die over it, and if a thread's damage is minimal, it may be possible to reform the threads by running a nut up and down them, though that runs the risk of the nut fusing to the thread (galling).

Will Loctite work on stripped threads?

Loctite® Form-A-Thread® It restores worn, stripped or damaged threads and eliminates future corrosion, galling, seizing, and rust, and allows up to 128 ft. lbs. of torque between -65°F to 300°F. It permanently repairs stripped threads and fasteners in five minutes (up to SAE Grade 5 English and 8.8 metric).

How do you fill screw holes in metal?

Epoxy or Tape Epoxy and tape are two common no-weld hole repair options. These do-it-yourself approaches are effective when repairing a small hole rather than a significant tear. Specialty epoxy and tape products are designed to patch steel and metal.

How do you fix a thread without a tap?

0:442:11Easily repair a cross threaded hole without a tap! - YouTubeYouTubeStart of suggested clipEnd of suggested clipSlide to the bolt will make our act as a cutter when it gives it a relief for the material to getMoreSlide to the bolt will make our act as a cutter when it gives it a relief for the material to get into the slide. Once you run that through the thread your bolts for reading with its.

What is thread repair?

Thread Repair Inserts are used to quickly and permanently restore tapped holes, which have been stripped or damaged due to wear, corrosion or over torque.

How do you make a new thread in a hole?

2:075:05HOW TO TAP NEW THREAD FOR A BOLT - YouTubeYouTubeStart of suggested clipEnd of suggested clipLine up your tap. Just like that and tighten them in place. Okay this is the most important andMoreLine up your tap. Just like that and tighten them in place. Okay this is the most important and trickiest bit is to get this nice and square so you want to try some level when starting up the hole.

What is thread repair insert?

Thread-repair inserts come in a variety of materials and in a myriad of designs from domestic and overseas manufacturers. Timed thread body inserts, wire coil inserts and keyed inserted make up the three major families of thread inserts you’ll likely encounter.

What size drill do I use for a M10x1.25?

First, you would drill the hole with a 10.25mm drill (a standard M10x1.25 thread would use a much smaller 8.75mm drill). Then you would use an M10x1.25-S.T.I. tap. This S.T.I. version of the tap will have a major diameter of up to 11.787mm, whereas a standard M10x1.25 tap is about 1.5mm less in diameter.

Can you have a thread failure in the same hole again?

Done right, you’ll never have a thread failure in the same hole again.

Is stripper thread more common than ever?

As a result, it’s no surprise that strippers are more common than ever before. Since most of the threads on today’s vehicles are made of materials with just one-third to one-half the hardness of grey cast iron, it’s no wonder that more threaded holes experience thread damage than ever before.

Can Keensert be threaded?

That’s a much bigger hole which can be beneficial in some application where severe corrosion is prevalent in the original threads. The Keensert would then be threaded into the drilled, tapped and cleaned hole with the Keensert installation tool. Thread locking compounds can be used due to its solid body design.

Is threading harder than fasteners?

While the materials where threads live have become softer, the materials used for fasteners have in many cases become harder. In fact, some of the super-alloys used in high-performance head studs and rod bolts have hardness levels approaching that of tap (every try to drill out a broken tap?). As a result, it’s no surprise that strippers are more common than ever before. Since most of the threads on today’s vehicles are made of materials with just one-third to one-half the hardness of grey cast iron, it’s no wonder that more threaded holes experience thread damage than ever before. It’s been said, “If a threaded hole in a softer metal uses a fastener that is installed and removed on a regular basis, a harder-material insert is a must.” Unfortunately, the cost and time involved with installing inserts at an OEM level means that it will never happen on a large scale. There may be a few key, high-stress locations in an engine block or suspension component, but 99 percent of all the threaded holes will not come from the factory reinforced with an insert.

How to repair a hole in a bolt?

Choose a thread tap that matches the original bolt's thread pattern. Dip the tap in a light oil; motor oil works great for this. Work the tap into the hole until hand-tight. Place a wrench on the square end of the thread tap and run the tap into the damaged hole a couple of times.

What is thread repair insert?

A thread-repair insert acts as a bushing between an over-sized hole and a properly sized bolt. A popular insert has an expanding coil design; others look like a standard bushing. A basic thread repair kit contains a thread tap, insert and an installation tool. Thread-insert installation requires a properly sized drill bit.

What happens when you tighten a bolt in a blind hole?

Trying to tighten a bolt in a debris packed blind hole often leads to stripped threads. Because a thru-hole, sometimes called a clearance hole, passes completely through the block, debris cannot build up. A tap creates female threads in a hole.

What happens when you put a blind hole in a bolt?

A blind hole stops before it passes through the block. Debris packed into the bottom of a blind hole can make a bolt bottom-out prematurely. This common error initially leads to loose fitting parts and leaking gaskets. Trying to tighten a bolt in a debris packed blind hole often leads to stripped threads.

How to tighten a bolt?

Press the bolt into the hole and twist clockwise. The bolt should turn easily. Once hand-tight, place the proper sized wrench or socket on the bolt's head and tighten as needed. When applicable, use a torque wrench and turn the bolt clockwise until it reaches the manufacturers recommended torque limit.

How to install a thread locker?

Place thread locker, if manufacturer recommended, on the appropriate surface. Screw the insert into the hole, stopping when the insert bottoms out. Remove the installation tool. Complete the repair and install a new bolt.

What happens when a bolt binds?

Once the bolt binds, the mating surfaces start to deform. Continuing to apply torque will strip the bolt-hole's threads. Use thread-locking material on bolts susceptible to vibration. After the thread-locking material dries, a semi-permanent bond forms, preventing the bolt from vibrating loose.

How do threaded parts work?

They are twisted by hand, and slowly work their way into hole being tapped. Threaded parts such as bolts, shafts, and other similar parts use dies to cut the threads. This is done in a similar manner as a tap, but the shaft of the part threads through the die as it cuts the threads.

What happens if threads don't match?

Some pitches overlap different sizes, so you have to use the chart to determine what size fastener you have. Thread size and pitch is critical to this type of repair. Using this style of pitch gauge, you can determine exactly what you have.

What is a taper in a blind hole?

The taper is there to guide the tap in the hole and to slowly cut the threads in fresh material. While this is great for through-holes, where the backside of the hole is open, these only get part of the job done when you are working with a blind hole, where the hole is closed. For that, you need a bottoming tap.

What is a taper tap?

The taper tap is the most common tap design. This is the style used for creating new threaded holes. The first 8 to 10 cutting flutes of the tap are not full, they gradually build up to the full thread size. The taper is there to guide the tap in the hole and to slowly cut the threads in fresh material.

Why do taps have tapered flutes?

The tapered flutes help ensure that the tap is centered and vertical. We ran the tap all the way through the part, so that the bottom threads were touched by the full flutes of the tap. The chips in the relief grooves of the tap are called swarf, they should be cleaned off before putting the tap away.

How many flutes does a plug tap have?

The plug tap is in the middle, it uses 3-5 gradual flutes. Each tap style serves a different purpose. From the left- taper, plug, and bottoming. If you are repairing damaged threads, either of these taps will usually work, unless it is a blind hole, in which you need to use a bottoming tap.

What happens when you strip a bolt?

When you strip one out or break a bolt inside the hole, the threads are damaged. In some cases you can re-tap the threads with good results, but if the fastener is under high load or critical, then you will likely have to go to the next size up. These holes use taps, which cut threads into the metal.

What to do when you have a tapped hole?

When creating a new, larger tapped hole isn't optimal or possible, use of a thread repair kit is recommended. Thread repair kits allow you to remove the damaged threads that are stuck in a hole and replace them with new threads of the same diameter.

Why does my thread get damaged?

Typically, thread damage is caused when a tap or fastener breaks in a hole, when a fastener is installed incorrectly , when incorrect bolt torque is used, or when thread fretting occurs as a result of extended or extreme vibration ...

What is a thread repair kit?

They may also be used to create strong threads in soft materials including aluminum. Thread repair kits consist of a tapping tool, an insertion tool, and thread inserts. A tap wrench and drill will also be necessary when using a thread repair kit. The drill bit is not always included in the kit. The most popular type of thread insert used in ...

What is the tension between the insert and the walls of the hole?

The tension between the insert and the walls of the hole helps to keep the insert in place and keep it from unthreading. The helix has a small return at one end that engages with the kit's included insertion tool, allowing the insert to be screwed into the hole.

What causes thread damage?

Thread damage can occur as the result of one or more of these factors... Use of incorrect bolt torque specifications. Cross-threading or improper installation of fastener. Use of incorrect fastener size or thread pitch. Thread galling caused by engagement with fasteners with a similar material hardness.

What is oversize thread repair?

Oversize Thread Repair Method Sometimes the most straight-forward repair method is to simply drill out the stripped thread and either tap or threadmill the hole for the next larger size.

How to insert a coated male fastener into a female thread?

Insert the coated male fastener into the female thread using a twisting motion. Center the fastener in the hole , and remove excess material. Do not apply torque to the fastener at this point. Following the instructions in the kit, allow the epoxy compound to cure before removing the fastener.

What is thread insert?

In many situations, thread inserts are ideal to repair stripped threads. Thread inserts are also commonly used in new part designs because of the many benefits that they offer.

What are the disadvantages of using a mix of thread sizes in a bolt hole pattern?

Disadvantages: The perception of using a mix of thread sizes in a bolt hole pattern is usually undesirable. A mix of thread sizes requires a non-standard selection of fasteners, different torque specifications, and is cosmetically obvious.

What are some factors that may require a custom thread insert design?

Some factors that may require a custom thread insert design include... Non-standard material of manufacture. Non-standard thread type and/or pitch. The dimensions of the required insert (wall thickness, diameter, or length) is not offered as a standard product.

What is a thread repair insert?

Thread repair inserts, allow for threads to be repaired, recreated, or reinforced to the original bolt size and pitch. Solid inserts which are often made of stainless steel or carbon steel, can not only be used to repair damaged threads but also to reinforce soft base metals like aluminum to be able to take a much higher torque.

Can you fix threads?

There are many not so ideal ways of fixing damaged threads by way of oversizing and cross threading; but what a lot of people don’t know is that there are many engineered solutions to properly fixing damaged threads. Even more problematic is that most people are only aware of coil based repair kits (like helicoil or permacoil).

Do self tapping inserts require a pretapped hole?

Self tapping (gardsert/seal-lock/ensat) Installation: The easiest method of all, these types of inserts do not require a pretapped hole, as they create their own threads as they are installed. They also do not require special installation tools and utilize a normal nut and bolt for installation.