Here’s a quick summary of the rebuild:

- Affix the jaw plates of the vice with he 4 Allen head bolts (restoring original orientation)

- Bolt in the toothed runner into the main body of the vice and apply a healthy amount of red grease

- Insert the threaded bar (after a greasing) into the sliding jaw side of the vice and slide the spring and washer onto...

How do I restore my classic vise?

I have always enjoyed restoring a vise and with some careful preparation you can achieve a better than new finish on your classic vise. The first step is to take apart the vise into it's component. Remove the jaws, main screw and swivel base if so equipped. If you run into any stripped bolts, watch the video below...

How to fix a broken vice?

Dismantle, clean and prepare the vice (or other tool that you're repairing). Anything goes at this stage, use wire brush, sandpaper, file. I did most of this with an angle grinder fitted with a wire brush. I will say at this point that I have many "vices" but one I have had for many years, is vices. so this is not my first.

Do you need to break down your vise completely?

At this point, regardless of what type of vise you’re working on, you should have it broken down completely and ready for a better evaluation of what you’re working with. Sometimes you’ll need to do a little bit of cleaning to have a good plan, but most things are pretty obvious at this point.

How do you remove a vise from its base?

With the dynamic jaw removed I’ll start on the main body of the vise. It it has a swivel base, I’ll remove that next. With some models all you have to do is loosen one or two swivel locks until they separate from the bolts underneath but some brands also have a large center bolt (shoulder bolt for us terminology geeks) that needs to be removed.

How do you fix a vice?

0:452:11How to Fix a Vice on a Workbench | Woodworking - YouTubeYouTubeStart of suggested clipEnd of suggested clipDrill again if necessary insert the bolt all the way in slowly. Place the vise where it is to beMoreDrill again if necessary insert the bolt all the way in slowly. Place the vise where it is to be fixed. Insert the bolts one by. One. You will need two nuts and washers to tighten the bolt.

Can you weld a broken vise?

0:1712:02Repairing a Broken Vise - YouTubeYouTubeStart of suggested clipEnd of suggested clipThere you could weld it how it is now but if you want to have some better strength you want to doubtMoreThere you could weld it how it is now but if you want to have some better strength you want to doubt for that out that way there's no fancier crack just splitting up into your world.

How do you reassemble a bench vise?

2:2610:35CRAFTSMAN Vise Disassembly & Repair - YouTubeYouTubeStart of suggested clipEnd of suggested clipThis inside there you can see it goes in like that there's a groove then it fits in do down. There.MoreThis inside there you can see it goes in like that there's a groove then it fits in do down. There. You can also use it a little WD on some places on this thing too.

How do you clean an old rusty vice?

Use a wire brush and a sanding sponge to remove flaking paint, rust, and caked-on dirt. Vacuum off debris created by wire brushing. The last step is to soak a shop cloth with denatured alcohol and wipe everything clean. The cleaned parts are ready for masking tape.

How do you repair a cast iron vice?

0:001:20Stick Welding A Cast iron Vise Repaired with 77 Electrode from ...YouTubeStart of suggested clipEnd of suggested clipBit i slightly warmed up the weld area with a map oxy. Torch. Final cleaning with a fine wire wheelMoreBit i slightly warmed up the weld area with a map oxy. Torch. Final cleaning with a fine wire wheel then slowly laid down the root pass a half inch at a time peening with a punch between passes.

Is cast iron hard to weld?

It is less malleable in comparison to steel or wrought iron. The heating and cooling cycles during welding cause expansion and contraction in the metal, inducing tensile stress. Cast irons do not stretch or deform when heated or stressed—instead, they crack—making them extremely difficult to weld.

How do you assemble a vice?

0:064:21Let's Assemble A Vise | Tech Tip - YouTubeYouTubeStart of suggested clipEnd of suggested clipSimply choose a mate connector at the centre of the shaft. And another at the center of the hole inMoreSimply choose a mate connector at the centre of the shaft. And another at the center of the hole in the base.

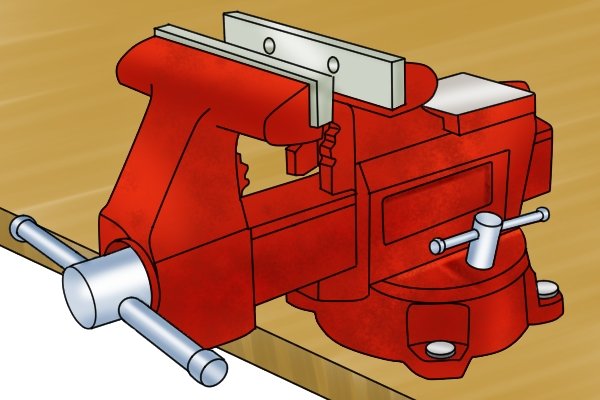

What are the parts of bench vice?

Different Parts of a Bench Vise and Their FunctionsThe Base. The base of the vise is the part that holds everything together. ... The Jaw. This is where everything stays. ... The Slide. This part moves when the handle is turned, applying pressure to the object. ... Main Screw. ... Handle. ... The Anvil. ... Serrated Jaws. ... Pipe Jaws.

What is the best grease for a vice?

Top 10 grease for vise: Comparison Table#Product1Lucas Oil Red"N" Tacky Grease, 1 Pound Tub, 16 Ounces (LUC10574)2Codirom Chainsaw Tool Set Chainsaw Sharpener Tools Set Chainsaw File 5/32 3/16 7/32 Chainsaw...3Felled Chainsaw Sharpening Kit in Hard Carrying Case - File Set, Guide, Depth Gauge, Stump Filing...7 more rows•Jul 8, 2022

How do you restore a metal vice?

1:497:28How to Restore a Bench Vise // DIY - YouTubeYouTubeStart of suggested clipEnd of suggested clipInstead. I went from sixty grit sandpaper all the way up to 220 grit you could see how quickly thisMoreInstead. I went from sixty grit sandpaper all the way up to 220 grit you could see how quickly this sander eats through the rest and in no time at all the piste looks good as new.

How do you restore steel?

0:201:30How to Remove Rust & Restore Surfaces to Bare Metal - YouTubeYouTubeStart of suggested clipEnd of suggested clipDrop your rusted tools or parts into the solution. And let them soak. Check back every few hoursMoreDrop your rusted tools or parts into the solution. And let them soak. Check back every few hours until all the rust is dissolved. And your hand tools back to bare metal.

How do you restore antique metal?

1 - Make a paste from 3:1 parts salt and lemon juice. 2 - Apply the salt-lemon paste with a paper towel. 3 - Scrub rust away with a scrub pad using firm pressure and small circular motions. 4 - ipe the rust and excess rust-removal paste away with a damp paper towel.

How to repair a broken vise?

The first step in repairing is cleaning and prepping the components of the vise, which are broken prior to welding. Next, take the vise apart completely if required and carefully document it as you dismantle it to make it easier to put back together. Taking a few photos or notes is a great idea, or even bagging individual parts and labeling them.

How to clean a vise after welding?

One of the easiest ways to clean up your vise after welding is by grinding back the weld carefully with a grinder before sanding it. Leave as much as the weld there as possible, but if the component needs to be smooth, then carefully sand it back until it’s flush.

What is vise made of?

Vises are usually made from cast iron and can be welded with high ductile filler like Nickel alloys. The vise needs to be preheated to around 200 degrees before welding to avoid cracking. A repaired vise has a reduced ability to withstand mechanical stress. Therefore a replacement is generally more economically.

How to prevent a cast iron weld from cracking?

Try to weld in small one-inch sections or runs rather than trying to weld the entire piece in one continuous long weld bead. Peening or tapping the weld with enough force to leave a slight indentation can also help to prevent the weld cracking. Start peening from the weld crater backward towards the start of the weld.

What type of iron is used in vises?

Almost all vises are made using a type of cast iron known as ductile cast ir on. While it is one of the most challenging types of cast iron to weld and most time-consuming, it’s not impossible if you take the proper steps and follow procedures as closely as possible.

What is the role of a vise?

You need to remember that the role of any vise is to apply pressure to something and hold it in place securely while you’re working on it. Carefully think about some of the different jobs that you have done with your vise and what the consequences of that vise breaking during a similar job would be.

Can you repair a cast iron vise?

If you follow all of the steps outlined above, you have a good chance of successfully being able to weld or repair your cast iron vise. However, if you try to skip steps or rush the process, there is a good chance that the finished component of your vise will crack as it cools down or after it’s cold. It can also lead to your weld being internally weak and the repaired item breaking again once it is put into use.

What happens when you turn a vice over?

Upon turning the vice over it was very obvious that the center bolt had backed out. Over time after turning the vice back and forth on the vice the center bolt can loosen up and eventually fall out. A loose center bolt can also cause slop and wobble in both the swivel and jaw tightening since it is pretty much the main internal part of the vice.

What happens if you don't put spacer back in?

MAKE SURE you put the spacer back in for the bolt. If you don’t the base will be tight to the vice and you won’t be able to swivel it.

Step 2: Two Fixes

So to fix this kind of problem you have two options one is to weld this and second is to make the jaw completely out of scratch and in my case I try both of them. I think if I am able to save it just by simple welding then this instructable is never going to happen but that didn't work for me.

Step 13: Admire the Work

If you like and also have some suggestions than definitely leave your comments down below.

Where are the pins on a vise?

The nut is also held in place by two 1/4″ dowel rods that are commonly called “pins” and can be seen on the side of the vise near the back. Depending upon the vintage of the vise there can be slight differences.

Why take jaws off of a vise?

On vises that have removable jaws I normally take those off first because you sometimes have to lean on the screws/bolts pretty hard, and it’s easier when you have the extra mass of the vise to resist the torque.

How to cut a pin in half?

You may have to use a torch, or sawzall with a small blade to cut the pin in half. If you’re lucky, the pin holes line up from one side to the other. If that’s the case, you can use a punch and hammer to drive one pin through to the point it makes contact with the pin on the other side, and drives it out.

How to remove a Wilton nut?

The first thing you’ll need to do is use a dowel or steel rod that will fit through the nut, from front to back, and use that to knock the dust cover out of the end.

What to do if pin holes don't line up?

If the pin holes don’t line up, or you’re not sure, it’s a good idea to pick another method of getting the pins out. Some folks use an allen wrench that just fits inside the nut. They make sure the short end is in the pin hole, and then they tap on the long end with a hammer.

Why don't pins protrude into the center of a nut?

The pins don’t protrude into the center of the nut because that’s where the spindle will be when the vise is closed. Removing the pins is sort of it’s own subject, and might get you using “colorful” language, but it’s not impossible. There are a couple of things to know about removing the pins before you get started.

What is the collar on a Parker vise?

More commonly, vises have an internal collar with a set screw, or a heavy clip on the inside of the slide that needs to be loosened before you can remove the spindle.

How to clean a paint job?

Clean all parts with solvent, (turps, thinners etc.) to remove any dust, grease or oil and take a good long look at your job. If you're happy with your base then proceed, if not, now is the time to improve the finish.

Can old tools be brought back to life?

With a little tweaking (well sometimes a lot...) an old tool can be brought back to life and be useful for another lifetime. The quality is often superior even if they are a little slower or take up a little more room...

How to get dirt off a vise?

I prefer to put on gloves and start soaking all the parts with penetrating oil. The penetration oil will break down grease and dirt and leave a nice sheen to your vise parts. I am currently using PB Blaster but WD-40 or Liquid Wrench will do just fine. The idea is to get the dirt and grime off the vise while providing some lubrication and thin film to prevent future rust. Use a rag or even fine scotchbrite pads to get tough stuff off.

How long to soak a vise?

Simple Green or Purple Power seem to be the most popular water-based solvents used. Get a 5 gallon bucket and soak for 24-48 hours. No hard work and it's supposed to remove paint and grime pretty well. Con is the cost as Simple Green can be $10/gallon but it can be reused several time. This method does not alter the base metal and paint may need to be scuffed for good adhesion.

What paint should I use on a Wilton vise?

I have found the best paint to use on Wilton vises is Verde Green from Rustoleum

How to prevent wire from getting in your eyeball?

Always wear safety glasses and a full face shield to prevent slivers of wire from making a home in your eyeball! Also be aware that sharp corners can grab the wire wheel and throw parts or grab the drill out of your hands. For large vises wire wheeling may be your only viable option.

Do vises need pictures?

While vises are fairly simple in design, take pictures if you believe you will be confused upon reassembly. It's also a good idea to have a small container handy for small parts to keep them from getting lost.

Can you restore a paint vise?

The answer lies with the end use in mind. If you are a collector and 50% or more of the original paint is present, my opinion is to not restore it. If there are 5 layers of paint or the original paint was removed to repaint, then a restoration is a good idea. If you are not a collector and simply want a vise to throw on your bench and use then the decision is easier. Either restore it or don't, totally a personal decision as you won't ruin the value either way.

Can you use a paint stripper on multiple layers?

Paint Stripper: If you are dealing with multiple layers of paint, a chemical paint stripper may be needed. There are some nasty chemicals out there that work great buy require caution when applying. Wear gloved and follow all safety instructions when dealing with these chemical paint strippers. It will not leave a good mechanical surface for primer/paint to stick but may save you time over using a wire wheel when you have a lot of paint to remove.