Shaft Repair

- Prepare the shaft by undercutting the worn area according to the following guide: shaft diameter 1/2" to 1"-1/16...

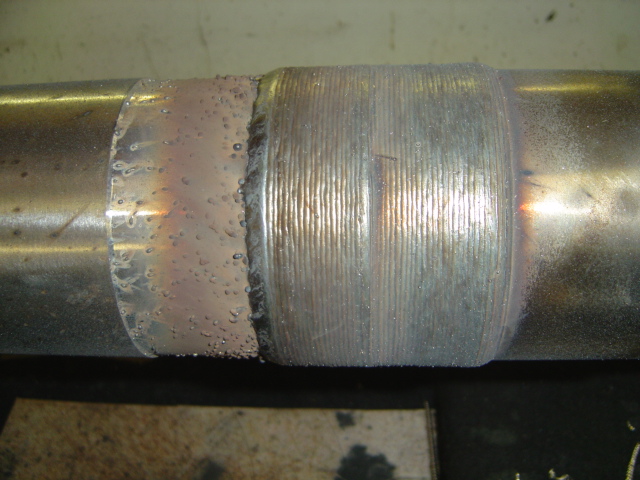

- Cut a thread pattern into the shaft, shallow on small diameter shafts, deeper for larger diameters (Fig.2).

- 3)Clean thoroughly with Metal Prep II™ Degreaser. Apply a very thin layer of ML400 Machinable Repair™ to the threaded...

Full Answer

Why do bearings wear away from the shaft?

Surely the metal is being worn away because of movement between the bearing and shaft. I have seen it happen when bearings were not properly fastened to the shaft--for example, set screws were not torqued properly. Vibration and temperature changes can put stress on these mating surfaces, and on the bearings.

What is the best way to repair a worn shaft?

Restoring dimensions in a worn shaft is an easier task. Although overlaying with fused powder or copper alloys can be done with an oxyacetylene flame, without melting the shaft material, the process still softens the steel. Plasma thermal spray is the preferred method, because the shaft material is heated minimally.

What happens if you don’t replace your shafts?

Additionally, oversized keyways, a crucial component that connects the rotating equipment to the shaft, may cause shaft dysfunction. Worn and damaged shafts can shut down the entire machine. Therefore, worn shafts may hamper or halt production and result in revenue loss.

How do you fix a broken bearing housing?

If the bearing housing is damaged already, you can patch it up by putting punch marks using a center punch around the housing. The punch marks will create raised dents all around the bearing housing that will fit with the bearing a bit tighter. A Loctite retaining compound can also be added to fill up the gaps.

Can a worn shaft be repaired?

Conventional Shaft Repair Methods Worn and damaged shafts are conventionally repaired using a hot process (welding/machining or hot metal spray/machining). If not carefully controlled, these conventional methods will cause residual damage to the shaft. They also require the disassembly of the machine.

How do you fix a bearing on a shaft?

2:063:42How to Remove and Install a Bearing with Timken Shaft ... - YouTubeYouTubeStart of suggested clipEnd of suggested clipTechnology works just like the conventional set screw clamped bearing. So maintenance people don'tMoreTechnology works just like the conventional set screw clamped bearing. So maintenance people don't need to learn a new process. Just tighten the two set screws to get all the clamping force you. Need.

How do you fix a worn spline?

0:389:27Using Loctite 660 to repair a stripped splined shaft - YouTubeYouTubeStart of suggested clipEnd of suggested clipObviously have been worn down and they were filled with some kind of a gray epoxy jb weld orMoreObviously have been worn down and they were filled with some kind of a gray epoxy jb weld or something like that. And if you look inside the handle if you can see in there.

How do you fix something to the shaft?

0:121:23How to attach something to a smooth stepper motor shaft - YouTubeYouTubeStart of suggested clipEnd of suggested clipThe side there is a single hole for securing the hub to the shaft with a small screw in an allenMoreThe side there is a single hole for securing the hub to the shaft with a small screw in an allen wrench. When. You are putting the screw in you should be careful not to force it in misaligned.

How do you install a bearing on a shaft without a press?

2:323:23Pressing a bearing without a press - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo again we'll just put the bearing in there as straight as possible we'll line up the socket onMoreSo again we'll just put the bearing in there as straight as possible we'll line up the socket on there as straight as possible. And then give it a couple good. Thumps.

How do you press a bearing without a press?

11:4218:21PRESS IN Wheel Bearings- LIKE A PRO WITHOUT A PRESS! - YouTubeYouTubeStart of suggested clipEnd of suggested clipWith that race so because it's gonna come flush we want to make sure we use the flat side. So itMoreWith that race so because it's gonna come flush we want to make sure we use the flat side. So it doesn't close if we use this cone. Side it you won't be able to press the bearing in fully.

Can splines be repaired?

One of the best features of Metalink™ polymers is their incredible compression strength. This allows repairs of spline shafts and keyways. Stripped spline shafts can be returned to service using Machinable Repair™ Compound by following this guideline.

What is a driveshaft spline?

Splines are ridges or teeth on a drive shaft that matches with grooves in a mating piece and transfer torque to it, maintaining the angular correspondence between them. For instance, a gear mounted on a shaft might use a male spline on the shaft that matches the female spline on the gear.

How do you spray weld a shaft?

2:5351:05SNS 300: Spray Welding a Blower Shaft - YouTubeYouTubeStart of suggested clipEnd of suggested clipWhat we'll do is just turn it down to just above the diameter of the threads. And it will machine aMoreWhat we'll do is just turn it down to just above the diameter of the threads. And it will machine a heavy sleeve and shrink a sleeve on there and then turn it back to size.

How do you weld a shaft?

0:0013:37Tig Welding Stainless Steel Shafts - YouTubeYouTubeStart of suggested clipEnd of suggested clipJust enough to put about a 1/8 radius in there where the Machinists can come back and machine a niceMoreJust enough to put about a 1/8 radius in there where the Machinists can come back and machine a nice radius in that corner. Very simple repair nothing to that one pass.

How do you fix a pulley shaft?

Some good ways rotating machine elements should be fixed to shafts:An epoxy or chemical bond like loctite 648. ... Set screw, obvious, low torque to medium torque. ... Press fit/heat fit - generally these are best when you want your pulley to idle, so you press a bearing on.More items...•

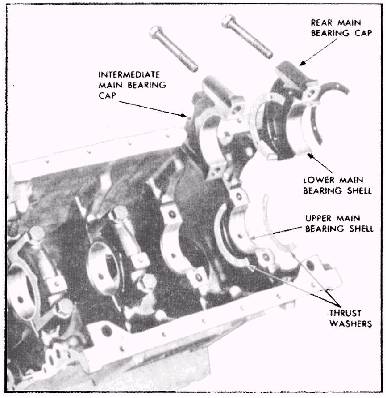

1. Electric motor bearing failure can wear out or damage shaft journals

Bearing Journal is the part of the shaft where the bearing is in contact or located.

2. Electric motor bearing failure can cause housing to wear out or damaged

Bearing housing is a part of the electric motor end shield that houses the bearing. It has a sliding fit or also called clearance fit which means the housing diameter is slightly bigger than the bearing outer race or OD of the bearing.

How bearing housings are repaired

Bearing housings are repaired by machining. This is done by installing a sleeve then by machining it down to the proper size. For example, you have an end shield that has a bearing size of 6209.

3. Bearing failure can cause the rotor to rub the stator causing damages

Bearings allow the rotor to spin inside the stator. Without the bearing that is not possible.

4. Motor with collapsed bearing makes it unrepairable

Neglect and inexistent motor maintenance result in bearing collapse. This happens when a portion or all of the bearing balls comes off from inside the bearing.

How to make a spherical shaft?

1) Prepare the shaft by undercutting the worn area according to the following guide: shaft diameter 1/2" to 1"-1/16 undercut; 1" to 3"-1/8" undercut (Fig.1). Dove-tail or square cut the ends. If the shaft is already worn to the recommended depth, go to step two. 2) Cut a thread pattern into the shaft, shallow on small diameter shafts, ...

Can a metalink shaft be repaired?

Shafts that are damaged due to metal to metal friction may be repaired using a Metalink Machinable Repair™ Compound, as long as the entire contact surface is not worn away or it is being used for a bearing race fit.

What causes a shaft to wear?

Contact between a rotating shaft and a seal causes shaft wear on crankshafts, transmission and driveshafts. Dirt or other abrasive particles can collect under the seal lip and eventually cause a groove in the shaft surface. Grooves from shaft wear can allow oil to leak out, which can result in bearing damage and failure.

How to install a Kwik Sleeve?

Installation. 1. Thoroughly clean the surface where the seal contacts the shaft. Carefully use a fine file, emery cloth or honing stone as appropriate to remove any debris, nicks or burrs. 2.

What is a Timken Kwik Sleeve?

If you can catch your fingernail in a shaft groove or seal wear track, a Timken Kwik-Sleeve can be installed to prevent leakage. It’s a precision-engineered sleeve made of stainless steel and then hard chromed for extended life. Because of its thin-wall design, a Kwik-Sleeve can be used without changing the size of the seal ...

Can you use a Kwik seal without changing the size?

Because of its thin-wall design, a Kwik- Sleeve can be used without changing the size of the seal and its finish is ideal for lip-sealing applications. No expensive preparation or machining is required before mounting. Each Kwik-Sleeve comes with a removable installation flange and its own installation tool.

Can a Timken Kwik Sleeve refinish a shaft?

Grooves from shaft wear can allow oil to leak out, which can result in bearing damage and failure. Kwik-Sleeve from Timken is a fast, economical and effective way to refinish a seal-worn shaft, according to the company. If you can catch your fingernail in a shaft groove or seal wear track, a Timken Kwik-Sleeve can be installed to prevent leakage.

What happens if a shaft is broken in two pieces?

If the shaft is broken in two or more pieces because of fatigue cracking across most of the section, not much can be done to restore it to a useful part, except possibly in exceptional cases by special means (see example in a later paragraph). But before you throw a broken shaft in the scrap bin, investigate the failure.

Why are shafts important?

Shafts are important, highly stressed mechanical elements used to transmit rotary motion from a driver unit to a driven part. Like any other component, a shaft can fail by one of a series of failure modes.

What is a shaft made of?

Shafts commonly are made of hard steel. Welding procedures can affect repairs in many ways. High-alloy steel is prone to cracking when welded, unless special procedures, such as preheating, are put in place.