Instructions.

- Shut off the electricity and drain the air tank. Unplug the air compressor’s power cord from the wall outlet. Pull the ring on the safety valve to ...

- Remove the compressor shroud.

- Disassemble the pump head.

- Remove the fan.

- Remove the piston and sleeve.

Can You rebuild an air conditioner compressor?

Whether you can rebuild a central air conditioner compressor motor is not a simple "yes" or "no" question. No, it cannot be rebuilt in the field when servicing a central air conditioning system. Defective motor compressors are replaced in the field with new or reconditioned units.

How to rebuild an injector pump?

How to Rebuild an Injector

- Obtain Rebuild Kit. The first step in the repair process is to obtain an injector rebuild kit. ...

- Take Injector Apart. Remove the O-rings at either end of the injector and soak it in carburetor cleaner overnight. ...

- Clean Injector While Applying Power. The injector is controlled by a solenoid which opens a valve. ...

- Rebuild Injector. ...

How to replace the oil in an air compressor?

- Like a car engine, the oil in the compressor will run easier if it’s warm. ...

- Open the fill port to allow air to flow more easily down into the sump.

- Position your drain catchment / funnel or whatever you’re using to help contain the oil, and carefully open the drain plug. ...

How do you preform air compressor maintenance?

To do this:

- Determine how many hours per day the compressor is used. Remember to only record the actual run time in hours, and to do this accurately, use a stopwatch to monitor ...

- Determine how much power (or wattage) the compressor is using while operating (this can be found on the compressor's nameplate). ...

- Determine the total kilowatt hours used. ...

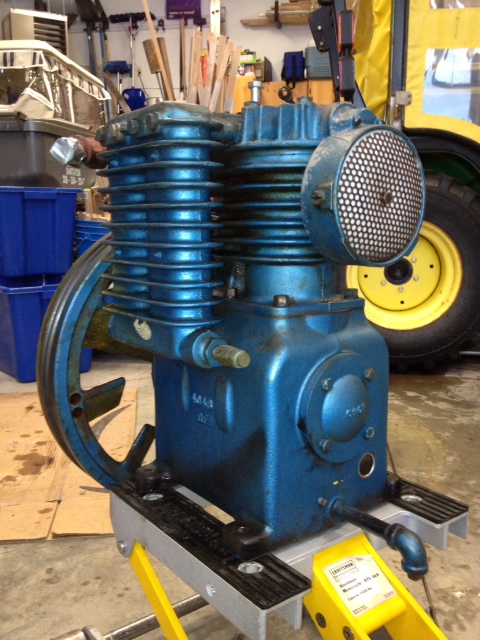

Can you rebuild air compressor pump?

Rebuilding the air compressor pump restores the pump's ability to efficiently compress air. If the tank won't build pressure because the pump seals or valve plate are worn, rebuild the pump using the manufacturer-approved air compressor parts. Most air compressor models use a kit for rebuilding the air compressor pump.

How do you know if your air compressor pump is bad?

To diagnose the problem, remove the hood, run the compressor for a few minutes, then shut it off and unplug the compressor. Feel around the motor parts for any sort of air draft. Chances are, the leak will originate from the tank valve, in which case you will need to remove and clean or possibly replace the valve.

What causes an air compressor not to work?

If your compressor is failing to work properly, it could simply be from a nearly empty oil tank. Power switch failure — When the compressor fails to power on, it could be due to a lack of contact between the pressure switch and inner circuitry. This can possibly be remedied with adjustments to the pressure switch.

How do you test an air compressor pump?

1:136:19Ingersoll Rand Reciprocating Air Compressor - YouTubeYouTubeStart of suggested clipEnd of suggested clipNext thing to try is a pump up test this will show you if the compressor has taken too much time toMoreNext thing to try is a pump up test this will show you if the compressor has taken too much time to build pressure to do a pump up test empty the air tank. Close off the service valve at discharge.

What is the most common cause of compressor failure?

Overheating is a common cause of compressor failure, and there are many factors at play. If direct sunlight falls on your outdoor unit and there is inadequate ventilation around it, it makes your unit's compressor overheated. High voltages can also damage the motor causing the compressor to overheat.

How do you fix an air compressor that won't build pressure?

What to Do When Your Air Compressor Won't Build PressureConduct a pump up test. ... Keep filters clean. ... Assess air demand and screen for leaks. ... Check all of your compressed air system valves. ... Evaluate belt condition. ... Inspect pump rings. ... Assess motor capacitors. ... Examine your air/oil separator.

Can an air compressor be repaired?

Air compressor repair can be simple. The air compressor unloader valve is what makes the “psssssst” sound when the motor shuts off after reaching operating pressure. It's actually venting the residual pressure from the compressor head so the motor doesn't have to work as hard on the next startup.

How do you reset an air compressor?

0:000:55How to reset/restart your air compressor when it won't startYouTubeStart of suggested clipEnd of suggested clipAnd maybe other brands as well is a it has a hidden thermal reset button that if the the motorMoreAnd maybe other brands as well is a it has a hidden thermal reset button that if the the motor overheats is going to pop out and will stop you turning it on because.

How do you fix a compressor problem?

Compressor will not operate.No electrical power. Turn on power. Push the reset button.Low oil level. Check oil level. Replace your oil if necessary.Pressure switch not making contact. See pressure switch adjustment.Pressure in the tank is below the cut-in pressure.

What are 3 common issues problems with a pneumatic air compressor?

Common Problems of Air CompressorCompressor Failure. An air compressor failing to start is one of the most basic problems you may encounter when operating the machine. ... Bogged Down Issues. ... Air Leaks. ... Pressure and Flow Problems. ... Uncharacteristic Noise and Vibrations. ... Oil Problems. ... Extremely Hot Emissions.

How do I know if my AC compressor clutch is bad?

A bad AC compressor clutch may cause it....The main symptoms of a bad or failing AC compressor clutch include:Higher Cabin Temperatures.Loud Noises.Clutch Stopped Moving.Inability to Turn Air On or Off.Leaking Refrigerant.

How can I test my car AC compressor?

0:468:14How-to Test for AC Compressor Clutch Function - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo what I'm going to do is this is a brand new AC compressor. And clutch and this is the example ofMoreSo what I'm going to do is this is a brand new AC compressor. And clutch and this is the example of what should happen if you run power to the power wire on your AC compressor. This is where the

What do I do if my AC isnt blowing cold air?

If air is coming out of the supply vents, but it isn't cold, there are a few things you can try:Check the Thermostat Fan Setting. ... Replace Your Filter. ... Inspect the Outside Unit. ... Check Your Thermostat. ... Check Your Air Filter. ... Make Sure There is Electricity Going to Your AC.

How to turn on a compressor?

We offer these tips regarding power and wiring that might affect your machine’s ability to turn on: 1 Always plug your compressor directly into an outlet, never a power strip. 2 Use three-prong extension cords that are less than 25 feet long to reduce resistance. They should also be at least 10 gauge. 3 Check to see if the compressor has tripped your circuit breaker. Repeated circuit breaker issues could be a problem with the air compressor wiring, an electrical circuit of insufficient amperage, or your electrical panel. If other machinery making the same electrical demands doesn’t trip your breaker, the problem is probably with the compressor. 4 Check to see that rodents or wear and tear haven’t frayed any wiring. 5 Make sure the contact is good between the power switch and internal circuitry. Sometimes switches need tightening due to vibration, and old switches may need replacement.

What happens when an air compressor goes bad?

When something goes wrong with your air compressor, it can result in lost work time and profitability. Here’s a look at the most common air compressor problems and some fixes you can try yourself to get up and running again.

What are the problems with antler pumps?

Less common problems. While the six problems listed above are the ones we see most frequently at Antler Pumps, there are other issues you may observe. Here are a few more air compressor problems and some things to try on your own to fix them: Oil in reservoir has a milky appearance: air intake needs to be less humid to reduce air in the oil. ...

Why does my air compressor have a repeating circuit breaker?

Repeated circuit breaker issues could be a problem with the air compressor wiring, an electrical circuit of insufficient amperage, or your electrical panel. If other machinery making the same electrical demands doesn’t trip your breaker, the problem is probably with the compressor. Check to see that rodents or wear and tear haven’t frayed any ...

Why won't my air compressor stop running?

If you have a compressor that won’t stop running, it’s likely due to one of two causes. The pressure relief valve may be faulty. This makes the tank too highly pressurized and dangerous to use. Disconnect the air compressor from its power source and have it professionally serviced.

What to do if your gauge drops?

If the gauge drops, you have an air leak. Disconnect the hose after performing the steps above . If the gauge stops dropping, you know the hose is the leaky element. Just like checking for a leak with a vehicle tire, you can apply liquid soap around connections and couplings to see if bubbles appear.

Air compressor stalling? Save money and fix it yourself

A faulty air compressor unloader valve can cause the compressor to stall out, but replacement valves are readily available and the fix is easy and inexpensive.

Replacing the unloader valve

Slap two open end wrenches on the compression fitting and loosen the nut on the air line. Pull it out of the fitting.

Required Tools for this Compressor Repair Project

Have the necessary tools for this DIY project lined up before you start—you’ll save time and frustration.

Required Materials for this Compressor Repair Project

Avoid last-minute shopping trips by having all your materials ready ahead of time. Here’s a list.

1. Disconnect The Air Compressor From The Power Source

The very first thing you will have to do is to disconnect the air compressor from the power source. This can be done by either unplugging it or turning off the breaker that is supplying power to it.

2. Remove The Pump Cover

The pump cover is located on the top of the pump. There are usually several screws that hold it in place. Remove them with a screwdriver to take off the cover.

3. Disconnect The Hoses From The Pump

Next, disconnect all of the hoses that are connected to the pump by unscrewing them. If you have airlines running through your walls or ceilings, make sure to turn off all of those valves as well.

4. Locate The Screws That Hold The Pump Together and Remove Them

Now, locate all of the screws that hold the pump together. There are usually several on each side. Remove them with a screwdriver to take the pump apart.

5. Take The Pump Apart and Clean All The Parts

Once you have removed all of the screws, take the pump apart. Be careful not to lose any of the small parts. Clean all of the parts with a brush or a rag until they are free of dirt and oil.

6. Replace Any Broken Parts, Including Seals, Bearings, Or Shafts

If any of the parts are broken, replace them now. This might be seals, bearings, or shafts. Make sure that all of the parts are clean and free from debris before replacing them.

7. Reassemble The Pump With New Pparts If Necessary

If any of the parts needed to be replaced, now is the time to reassemble everything. Make sure all of the screws are tightened so that they won’t come loose while operating the air compressor. If there were bearings or shafts that needed to be replaced, gather those as well as begin putting them back together.