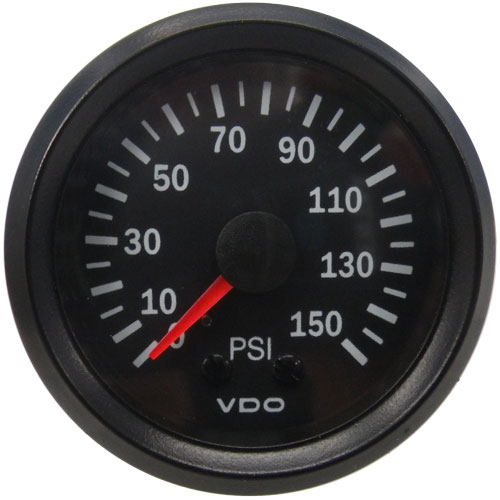

5 Techniques to Adjust or Repair a Pressure Gauge

- Opening a vent to release pressure build-up

- Opening the Glass (or plastic cover) then removing the needle.

- Rotating the screw located at the face of the scale.

- Adjusting the knob at the lower side of the pressure gauge

- Adjusting the screw located at the gauge needle pointer itself.

Full Answer

How do I get my pressure gauge repaired?

Send Us Your Pressure Gauges. Ship your gauge to us for repair. Step 1 - Old gauges are received for refurbishment. Step 2 - Gauge is completely disassembled and evaluated. Step 3 - Interior and exterior surfaces of the case and ring are cleaned and repainted at our paint station. Mounting threads are also cleaned.

What is the repair and refurbishment process for a gauge?

Gage-it's repair and refurbishment process insures that the refurbished gauge meets all of the standards of the original gauge. Gauges found by our inspection to be beyond economical repair will be returned, upon request, to our customer on a no charge basis. Our six-step process is detailed below: Before After Pressure Gauge Repair & Calibration

What is the highest pressure gauge on the market?

High Pressure Gauges NOSHOK 4" 40-400/402, 1/2" LM NOSHOK 4" 40-402, 9/16-18 UNF Liquid Filled Gages Ametek USG 4" 656, 1/4" LM Ametek USG 4" 1555, 1/4" LM Ashcroft 4" 8008A, 1/4" LM

What is the size of the noshok pressure gauge?

High Pressure Gauges NOSHOK 4" 40-400/402, 1/2" LM NOSHOK 4" 40-402, 9/16-18 UNF Liquid Filled Gages Ametek USG 4" 656, 1/4" LM

Can a pressure gauge be repaired?

At Gage-it we're experts in the repair and refurbishment of pressure gauges and related accessories. With over 45 years experience in the gauge repair industry, Gage-it can restore just about any gauge regardless of condition to its new or original condition.

What to do if pressure gauge is not working?

1:243:09How To Burp A Pressure Gauge - YouTubeYouTubeStart of suggested clipEnd of suggested clipEven vacuum or in this case a compound range was reached both vacuum. And pressure can. The smallMoreEven vacuum or in this case a compound range was reached both vacuum. And pressure can. The small buildup of pressure can push the very sensitive Bourdon tube in here. And move the needle off of 0.

How do you fix an air gauge?

2:033:13How To Fix A Pressure Gauge Pointing Off Of Zero - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd thumb put it at the base of the gauge take your flat head put it put it up against the screw.MoreAnd thumb put it at the base of the gauge take your flat head put it put it up against the screw. And then you turn it clockwise to move it the pointer clockwise counterclockwise.

Is my pressure gauge broken?

Pressure gauge problems are one of the easier well issues to diagnose. If the PSI gauge doesn't ever move, then it is most likely broken. Another warning sign is a pressure reading when the system has no water in it. The pressure gauge is a tool that allows us to see how the system is operating.

What causes a pressure gauge to fail?

Pressure gauge failure can be attributed to one or more of these eight reasons: mechanical vibration, pulsation, extreme temperature, pressure spikes, overpressure, corrosion, clogging, and mishandling/abuse. Pressure gauges are an integral part of an application's warning system.

How do you test a pressure gauge?

To perform the test:Isolate the pressure gauge from the process using valves, or by removing the gauge from the process.Connect the gauge to the calibrator or reference gauge. ... For hydraulic pressure gauges it's important prime the system. ... When generating pressure allow a few moments for the measurement to stabilize.More items...

How do you clean a pressure gauge?

Thermocouple Tube CleaningThe first step for effectively cleaning a digital pressure gauge thermocouple tube is to remove it from the attached cable. ... Using a funnel, pour roughly a tablespoon of solvent into the sensor's stem. ... The solvent needs time to work, so allow it to sit for about an hour.More items...

How do I fix the pressure gauge on my bike pump?

1:402:59Floor Pump Service | Gauge Replacement - YouTubeYouTubeStart of suggested clipEnd of suggested clipOnce you have your thread lock on the threads of your new gage. You can drop it in and start toMoreOnce you have your thread lock on the threads of your new gage. You can drop it in and start to tighten it into place.

How does a pressure gauge work?

They consist of a semicircular and flat tube of metal, fixed at one end and attached to a sensitive lever mechanism at the other. As pressure increases inside the tube, the force of the fluid attempts to straighten out the curved tube.

How long do pressure gauges last?

According to NFPA 25, Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems, gauges shall be replaced every 5 years or tested every 5 years by comparison with a calibrated gauge.

How do you take apart a tire pressure gauge?

0:387:21How to disassemble, repair and calibrate an air pressure gaugeYouTubeStart of suggested clipEnd of suggested clipSo as you can see the the little air gun has a threaded fitting that the gauge fits into you unscrewMoreSo as you can see the the little air gun has a threaded fitting that the gauge fits into you unscrew that with a let's say a 9/16 wrench.

How do you make a pressure gauge?

0:245:04How Pressure Gauges are Made - YouTubeYouTubeStart of suggested clipEnd of suggested clipEach piece becomes a pressure sensing tube known as a Bourdon tube. Then a worker cuts lengths ofMoreEach piece becomes a pressure sensing tube known as a Bourdon tube. Then a worker cuts lengths of brass that he machines into connectors.

How do I fix the pressure gauge on my bike pump?

1:402:59Floor Pump Service | Gauge Replacement - YouTubeYouTubeStart of suggested clipEnd of suggested clipOnce you have your thread lock on the threads of your new gage. You can drop it in and start toMoreOnce you have your thread lock on the threads of your new gage. You can drop it in and start to tighten it into place.

How long do pressure gauges last?

According to NFPA 25, Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems, gauges shall be replaced every 5 years or tested every 5 years by comparison with a calibrated gauge.

How does a pressure gauge work?

They consist of a semicircular and flat tube of metal, fixed at one end and attached to a sensitive lever mechanism at the other. As pressure increases inside the tube, the force of the fluid attempts to straighten out the curved tube.

How do you replace a water pressure gauge?

5:0111:34Replace and Adjust Pressure Switch and Pressure Gauge for Well WaterYouTubeStart of suggested clipEnd of suggested clipGo put it in. Alright let's go ahead and put it in the new pressure. Gauge. You go ahead and threadMoreGo put it in. Alright let's go ahead and put it in the new pressure. Gauge. You go ahead and thread on the pressure. Switch.

1. There are differences between diaphragm pressure gauges and standard pressure gauges in terms of pressure measurement principle and structure

The pressure measuring principle of the standard pressure gauge is to be calculated into the pressure measuring spring. The spring tube is under pressure, and it will produce elastic displacement and drive the connecting rod and the central gear deflection. The pointer is mounted on the main gear shaft to show the pressure measurement value.

2. Analysis of the causes of faults in the use of diaphragm pressure gauges

2.1 The diaphragm pressure gauge is distributed in the TEC boundary zone, and the failure rate

3. Diaphragm pressure gauge servicing

We have overhauled more than one diaphragm pressure gauge, and we found that most of the failures are caused by the loss of silicone oil in the spring tube. So it can be said that the spring tube filled with silicone oil solves the key problem of diaphragm pressure gauge maintenance. But to the spring tube filled with silicone oil is not easy.

4. Calibration of diaphragm pressure gauges

Our diaphragm pressure gauges are supplied from abroad with the equipment and have a standard 1/2 NPT thread to connect the pressure gauge head. In addition, each diaphragm pressure gauge is provided with a connection flange. Therefore, we want to calibrate the diaphragm pressure gauge.

5. Conclusion

The diaphragm pressure gauges are widely used in oil transmission stations for the primary measurement of operating pressure. Still, they also have the problem of being damaged and expensive to purchase new gauges.