How to Lightly Restore an Anvil

- Degrease Anvil. If your anvil isn't covered in grease, you might be able to skip this step. ...

- Rinse Off Degreaser. Use water to rinse off degreaser. ...

- Wire Wheel to Remove Surface Rust. ...

- Use Evaporust Gel to Convert Remaining Rust. ...

How to restore an old anvil?

Such as:

- You can spend a lot of time and money and make your anvil worse off than it was originally

- Making the face more brittle and prone to cracking in welded areas

- Heating the face of the anvil can ruin its temper in all areas in contact with the weld bead

- Edges of your anvil won’t be able to hold up to heavy use and will start to chip out or deform

How much should I pay for an anvil?

To sum it up, the answer to how much an anvil will cost is, as with most purchases, a relative thing. A standard guideline of cost is $7-$9 per pound for a new anvil or $2-$4 per pound for a used one, but quality and durability are just as important as weight.

How to secure an anvil to a stump?

Square the top and bottom:

- Cut log of sufficient diameter to length somewhere around 2 inches longer than desired. How much extra length depends on the straightness of the cut.

- Determine the side of the base that is the most square and place it on the floor. ...

- Make a sled for the router out of quality 1/4 inch plywood with some side supports of 3/4 inch by approx. ...

What to use instead of Anvil?

Instead of an anvil, you can use any large, solid block of steel, which you can transform into a makeshift anvil at home. Some of the best options include railway tracks, scrap metal, or heads of sledgehammers. This article will also give a brief outline of how to use these anvil substitutes and how to create them.

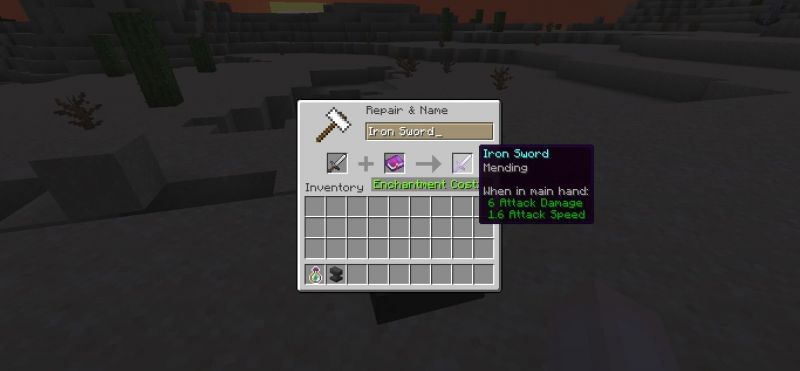

How do you repair a damaged anvil in Minecraft?

You cannot repair an Anvil. The Anvil will break if it's done. You can just build another one and place it on the old place of the Anvil. You just can repair Items at the Anvil.

Can you repair a cracked anvil?

Fixing A Cracked Anvil If you want to fix a cracked anvil, the basic steps you'll need to take are to sand it down, grind down the cracks a bit, and weld it. You want to grind all the surfaces you're going to weld to expose good, clean material. Make sure to get into any fractured chips or folds.

Can I resurface an anvil?

7:5213:03How to Repair An Anvil: Resurface An Anvil for Optimal Anvil RestorationYouTubeStart of suggested clipEnd of suggested clipAnd it helps to take and actually have a sanding disc that you can actually go across the entireMoreAnd it helps to take and actually have a sanding disc that you can actually go across the entire surface of the anvil to take and get it nice and clean. And you don't want this to be a mere finish.

How do you weld an anvil repair?

1:2310:12Blacksmithing For Beginners - Welding and Resurfacing an AnvilYouTubeStart of suggested clipEnd of suggested clipIf you start welding on a cold. And Vil the heat from the weld is going to get sucked into the bodyMoreIf you start welding on a cold. And Vil the heat from the weld is going to get sucked into the body of the anvil. And the welds are going to cool too quickly and they're going to become brittle.

How do you restore rusty anvil?

4:456:07My Anvil Rusted! Now What? - YouTubeYouTubeStart of suggested clipEnd of suggested clipUse it use the anvil throw a little oil on it wipe it down with some rags eventually you won't evenMoreUse it use the anvil throw a little oil on it wipe it down with some rags eventually you won't even notice the rust anymore the rust will just kind of pop off.

How do you stop an anvil from rusting?

Here are a few tips you can use to stop an anvil from rusting:Regularly use the anvil.Apply maintenance wax to your anvil.Add oil to the surface of your anvil.Clean and cover your anvil after use.

Can an anvil be welded?

Repairs to the horn of cast iron anvils is usually done by welding with the NI rod and grinding.

What type of metal is an anvil made of?

anvil, iron block on which metal is placed to be shaped, originally by hand with a hammer. The blacksmith's anvil is usually of wrought iron, but sometimes of cast iron, with a smooth working surface of hardened steel. A projecting conical beak, or horn, at one end is used for hammering curved pieces of metal.

How do you dress an anvil?

2:5710:35Dressing up a new anvil for my son. - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd i got me a 60 grit flap disc right though now we done came out sad look at the before we can getMoreAnd i got me a 60 grit flap disc right though now we done came out sad look at the before we can get started on them i need to say some safety things all right please use you some eye protection.

How to repair an anvil?

The most common ways to repair or restore an anvil are by either grinding down the surface, welding any missing areas, or both. However, if you’re a brand new blacksmith then trying to repair your first anvil can often do much more harm than good. If your anvil only has minor damage, try working around it. If an anvil you’re considering buying has ...

Why do anvils need to be repaired?

Chips, cracks, grooves, pitting, and dents can make an old anvil look really worn and damaged.

What is the face of a blacksmith's anvil?

The main areas where new blacksmiths might be worried about damage on their anvil is the face (the flat top surface where most of your blacksmithing work is done), and the horn (where most bending work is done.) Blacksmiths might also worry about rust or patina on their anvils and want to remove it as well.

What happens if you hit an anvil with a hammer?

Be especially careful on the very tip of your anvil’s horn. These small areas are prone to bending, breaking, or mushrooming if they’re repeatedly struck with heavy hammer blows. The edges of your anvil are also especially weak areas. All anvils will suffer some kind of edge damage over time.

How hot should an anvil be before welding?

Before you weld your anvil, you want to heat it up to between 350 and 450 degrees first. You can use a Tempil Stick to verify the temperature. Lifting a full-sized anvil can be hard, so you can use a more portable tool like a propane-fired weed burner to heat your anvil up. You can also use a wood fire.

How to fix rust on an anvil?

And hot steel will quickly start to remove rust from your anvil. Sometimes the best way to fix small damage or imperfections in your anvil is just to start using it. The constant pounding and heat will really start to make everything pretty flat and uniform before long.

How to stop anvil from spreading?

If your anvil just has a small crack that you want to prevent from spreading any further, that’s possible too. You can drill a hole at each end of the crack and that should stop it from getting any worse. Use a good build-up rod for welding. Avoid hard surfacing electrodes.

Can you repair an anvil?

You can just build another one and place it on the old place of the Anvil. You just can repair Items at the Anvil. This is the thing you see in the release logs called "Anvil repairing has been rebalanced" as it was way too expensive in older versions. You cannot repair an Anvil, even using another one.

Can you repair an anvil in Minecraft?

You cannot repair an anvil, so you have to make another one every time one anvil breaks. It is impossible to repair an anvil in the newest versions of Minecraft. You will need to make another one like in the picture below. The amount of time an anvil will last varies but on average it will be 25 uses.

Step 1: Cleaning Up Original Surface

If you have a cheap anvil that's made of cast iron or a soft material that you've already put to use and the face is pitted from the hammer striking it try to get it as flat as possible.

Step 2: Prepping the Plate

Now that you have your tool steel plate or whatever type of plate your going to use, you have to do a couple of things before you weld it on.

Step 3: Cutting Out the Hardy Hole

First thing you do is you drill holes where your going to cut the hardy hole slot out so that you don't have to cut as much. Then you cut the hole out.

Step 4: Drilling Holes in the Plate

This is optional but I did this to make the plate not have a hollow spot under the plate. So drill holes in random spots on the plate.

Step 5: Welding the Plate On

Now clamp the plate on and make sure it's where you want it. Then weld all the way around the plate twice for extra strength. Then fill in the holes with the welder a little above flush. Then grind the top smooth.

Step 6: Flatting the Top

Now get a sanding wheel on a grinder and sand the top lightly till it's flat and smooth. As you can see I drilled a hole all the way through and made the pritel hole.

Step 7: Rounding the Horn

Now get a grinding wheel and take of as much as you want so that you think it's round enough. Then get a sanding wheel on a grinder and smooth the horn.