Repairing a Small DC Electric Motor

- Clean It. If it needs it clean it with scotchbrite and soap to remove any corrosion and goo it doesn't matter that it gets wet you're going to ...

- Take It Apart. Place a small blunt blade between the drive gear and casing and leaver the gear off. ...

- Clean and Examine. ...

- Repairs. ...

- Reassembling. ...

- Other Motors 1. ...

- Larger Motor. ...

Full Answer

How do you fix an electric motor?

How do you fix a overheating electric motor? A great way to do this is to use an overload relay. The role of relay is to protect the motor from overloading and overheating. If this occurs, the relay then deactivates the motor until the issue can be resolved. Some overload relays can also be developed into microprocessor systems.

How do you troubleshoot an electric motor?

- Broken mounting holes or feet

- Darkened paint in the middle of the motor (indicating excessive heat)

- Evidence of dirt and other foreign matter having been pulled into the motor windings through openings in the housing

Who rebuilds electric motors?

Electric Motor Repair, Rewinds, & Parts. Eurton Electric specializes in electric motor repair & rewinding. Whether it’s an armature, field coil, motor, stator, or anything else that requires winding, we can repair it! Family owned and operated since 1933, Eurton Electric is proud to have the employee expertise to repair and rebuild what other ...

How to maintain electric motor?

Top Tips For Maintaining Electric Motors

- Develop a general maintenance and cleaning routine. Every company should have a cleaning routine in place if they don’t already. ...

- Check the motor’s lubrication. ...

- Regularly inspect the bearings. ...

- Reduce or eliminate vibrations. ...

- Inspect the rotor and stator. ...

- Record your findings. ...

Can you repair electric motors?

So long as the shell exists, a motor can be repaired and reconditioned. The key is to remember that eventually that motor will need a burnout and rewind before it is insulated again. Then, with proper maintenance and smart reconditioning, there is no limit to how many times you can have that motor repaired.

What causes an electric motor to stop working?

Low resistance is the most common cause of failure in electric motors. It is also often the most difficult to overcome. Under conditions such as overheating, corrosion or physical damage, degradation of the insulation of the internal windings of the motor may occur.

Is it worth repairing an electric motor?

If the extent of the damage to your motor is not too significant, then we would always advise going for electric motor repair. It is a much more cost-effective and environmentally friendly solution, especially if only certain parts of the motor need repairing.

How do you fix a small electric motor?

3:0325:41How to Repair a Small Electric Motor - YouTubeYouTubeStart of suggested clipEnd of suggested clipAlmost all electric motors are pretty much very similar there they operate based off of the same.MoreAlmost all electric motors are pretty much very similar there they operate based off of the same. Same system so as you take things apart you're gonna want to watch your sequence.

What is the most common cause of electric motor failure?

Winding insulation breakdown and bearing wear are the two most common causes of motor failure, but those conditions arise for many different reasons....Shaft imbalanceDirt accumulation.Missing balance weights.Manufacturing variations.Uneven mass in motor windings and other wear-related factors.

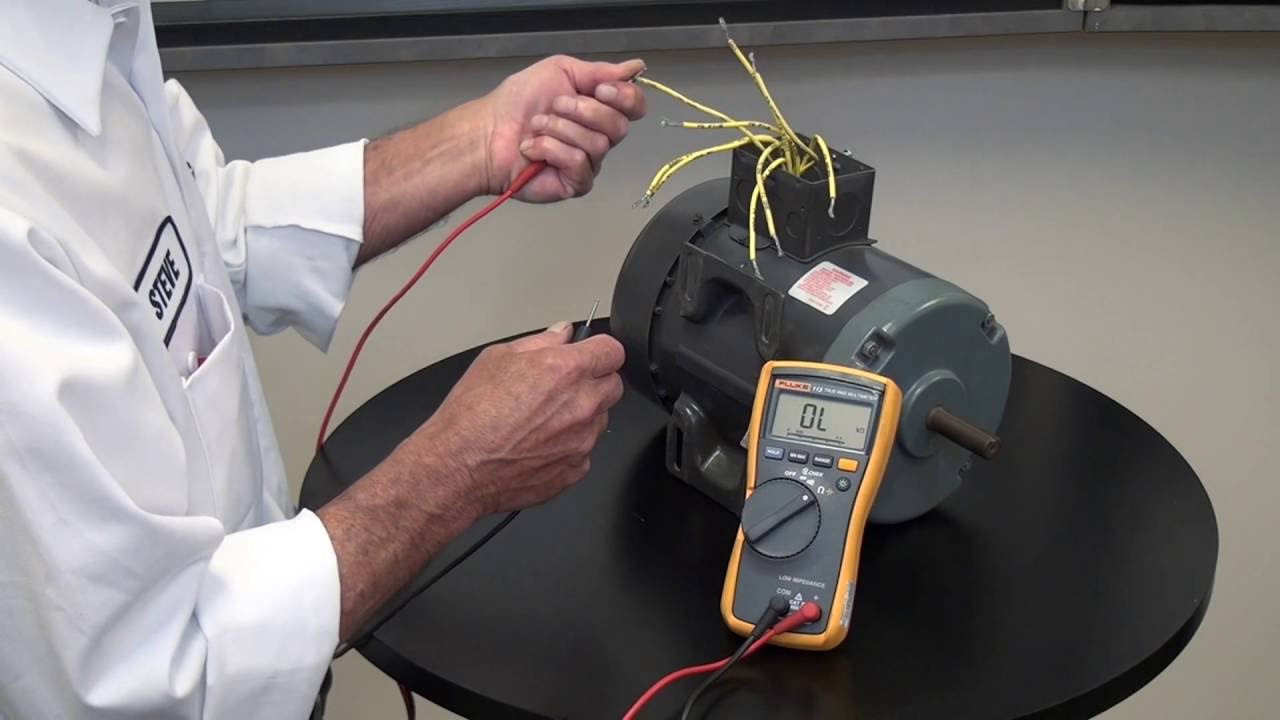

How do you diagnose a bad electric motor?

How To Check If an Electric Motor Is Going BadCheck the Bearings and Shaft. A motor's bearings are one of the most common components to go bad. ... Inspect the Motor Windings With a Multimeter. ... Test the Power With a Multimeter. ... Ensure the Fan Is in Good Shape and Secure.

How much does it cost to have an electric motor rebuild?

Motor shop “A” quotes come back as follows: $1000.00 for a recondition. $2000.00 for a rewind. $200.00 to repair a housing.

When should an electric motor be replaced?

It is a general rule that standard motors of 11kW or less should be replaced, as they are generally stock items available at short notice and are uneconomic to repair. However, testing/ dismantling to find the cause of failure is recommended.

Why do motors need to be rewound?

Rewinding an electric motor can improve insulation resistance and can improve the efficiency of your motor at the same time. Hiring a professional to rewind your electric motor can yield incredible results.

What does a capacitor do for an electric motor?

Motor capacitors store electrical energy for the motor to use. The higher the capacitance of the capacitor the more energy it can store. A damaged or burnt out capacitor may hold only a fraction of the energy needed for the motor if its capacitance is low.

How do you service a motor?

Simple checks and routine ac and dc motor maintenanceClean motor of any dust or oil.Check oil rings turn with shaft.Check oil level in bearings.Visually check for oil and grease from bearings.Technician to examine the starter switch, fuses and tighten loose connections.

How do you tell if a motor is burned out?

When a motor burns out, a short circuit occurs in the windings and the motor ceases to turn. You can test for a short circuit by checking the resistance of the windings with an ohmmeter; a reading of 0 ohms (Ω) indicates a short.

How long do electric motors last?

The answer to how long motors last will vary and is dependent upon many factors. Some manufacturers estimate 30,000 hours, while others state 40,000 hours. Some will say “it depends.” One thing is clear—a motor should last much longer with a conscientious motor systems maintenance plan than without one.

How to remove a motor from a winding?

Unplug the motor from its power source. Access the connections between the power cord and the motor windings. Remove the junction box cover plate, if there is one. (Make some photos showing the connections so you can make them correctly again, if you need to take them apart.) If there is no junction box on the motor, remove the end of the motor where the power cord connects to the windings.

How does a capacitor start an electric motor?

Capacitor start electric motors use a starting coil and a capacitor to create an advancing magnetic field in the stator (outer frame of the motor with its coils). This advancing magnetic field gives the rotor something to chase, causing the rotor to spin. (For example, put a bar magnet on top of a glass table. Bring another bar magnet up to it from under the table. Move the magnet under the table. The magnet above the table chases the magnet under the table in a crude form of an electric motor. The advancing magnetic field in the stator replaces the movement of your hand under the table.) That starting coil will be destroyed if it remains powered up in the circuit more than a very few seconds. Most motors use a centrifugal switch to disconnect the starting winding from the circuit as soon as the motor shaft builds most of its speed.

How to check for open circuit?

You have checked for shorts. Now check for opens. Follow the wires as best you can. The starting windings use a thinner wire than the running windings. Use the Ohmmeter to check for breaks in both windings. The resistance on each winding will be relatively low, but the starting winding will show a little higher resistance. If one of the windings shows an open circuit, look closely at where the wires attach to a terminal or to a heavier wire. Such junctions are the most common places for an open junction to happen. (I once repaired a "dead" Dremel tool. There was no indication of an open circuit in any of the armature coils. But, the field coil showed an open circuit between the two terminal pins. I looked closely and saw a break where the coil wire attached to one of the terminal pins. I scraped enamel from the wire as best I could and made a solder bridge to the terminal pin. It was not a perfect solder joint, but the Dremel worked again.) If you are not able to find the break in the coil circuit and repair it, the motor will need to be rewound.

How long does it take for an electrolytic capacitor to dry out?

It is not uncommon for an electrolytic capacitor to dry out and fail in audio equipment after 20 years or less. But, replacing a start capacitor without first checking for shorted or open windings, an open reset, and a faulty centrifugal switch will not make your motor run, if the capacitor is not really your problem.

What happens if a switch is worn?

If the switch is worn, the plastic spool on the motor shaft may not be exerting enough pressure on the plate that holds the contacts for them to close fully. See the second photo. I tested my switch contacts with the motor fully assembled. I inserted a screwdriver through an opening on the front of the motor and gently applied a little pressure toward the end of the shaft (away from the motor) to close the contacts while connected to an Ohmmeter.

How long is the start winding energized?

The graphic shows the circuit diagram for this type of motor. The start winding portion is energized for only a couple of seconds. Then the centrifugal switch locks out the components of the starting winding circuit. In the next steps tests will be done to eliminate probable causes.

Where is the capacitor on a motor?

Many motors have a domed cover on the outside of the motor, and the capacitor is under it . Motor capacitors are usually a cylinder with terminals on top. But, some capacitors in older motors may also be flat, like a short stack of 4 x 6 index cards.