How to Fix Broken Plastic

- Method 1 Repairing Small Pieces with Glue. Buy a tube of high-strength plastic glue. If you’re attempting to fix a...

- Method 2 Fusing Plastics with a Soldering Iron. Glue the broken piece back into place. Start by reconnecting the...

- Method 3 Solvent Welding Plastics with Acetone. Fill a glass container with acetone. Set out a drinking glass,...

What is the best way to repair broken plastic?

To fix broken plastic, start by getting some super glue or high-strength plastic glue. Then, apply some of the glue to the broken edges of the plastic. Next, press the broken edges of the plastic together and apply constant pressure for 30 seconds. You can also tape or clamp the pieces together so they stay in place while the glue dries.

How do you fix broken plastic parts?

Method 2 Method 2 of 3: Fusing Plastics with a Soldering Iron

- Glue the broken piece back into place. Start by reconnecting the separated surfaces and anchoring them with a powerful plastic adhesive.

- Heat up your soldering iron. Switch on the soldering iron and set it to the lowest temperature setting.

- Use the soldering iron to melt the edges of the plastic. ...

- Patch large holes with scrap plastic. ...

How can a person repair cracked plastic?

Method 2 Method 2 of 4: Using Hot Water

- Reconnect small cracks in plastic using hot water. Plastics often do not need extreme heat to become malleable enough to repair a crack.

- Fill a container of hot water and a container of cold water. Fill a bowl or container with enough hot water to submerge the cracked piece of plastic.

- Place the cracked plastic in the hot water. ...

How to fix a cracked retainer at home?

Over time the composite may:

- Get thinner after repeated abrasions from chewing and brushing

- Become debonded from the teeth due to a large impact (like getting hit in the mouth with a basketball)

- Fracture after one bites into a hard object directly on the retainer (like biting on ice)

Can you fix broken plastic parts?

If you have two separate pieces of plastic that need to be joined or if you have a crack, then you'll need to do some plastic welding. The basic idea is to apply heat to the edges being joined in order to melt the plastic until it is liquid enough to blend the edges together.

Can broken plastic be melted back together?

When the plastic casing of an object gets cracked or broken into pieces, most people just buy a new one; however, plastic is remarkably malleable and is quite easy to melt and reattach with a soldering iron.

How can I fix plastic permanently?

For best results, clean the plastic trim with isopropyl alcohol so there is no residue, only bare plastic. Use a microfiber applicator or foam applicator to apply Solution Finish Trim Restorer onto the plastic. Wipe off excess product with a clean towel and allow the plastic to dry for 6 hours.

What is the strongest glue for plastic?

The strongest glue to use on plastic is usually a two-part epoxy, like JB Weld PlasticWeld in a syringe. It adheres very quickly and strongly to most types of plastic, so you can form a fast, strong bond.

How do you bond two pieces of plastic together?

There are three types of glue you can use on plastic: polystyrene cement, super glue and epoxy glue. Polystyrene cement melts the plastic slightly, effectively gluing the pieces together into one. It's great for things like pipes or model kits, but if not used correctly, it can damage surfaces.

How to repair plastic parts?

Another highly effective repair method, plastic welding involves using a soldering iron to repair plastic parts together. Like plastic cement, plastic welding involves melting broken plastic parts together in order to put them back. Alternatively, plastic scrap can also be used to be melted along with the plastic parts. Plastic welding utilizes a soldering iron that is set at a low-temperature setting to melt the parts.

What is the best way to repair plastic?

Perhaps the most common method of repairing plastic parts and products, glue and cement are also used when it comes to assembling various parts. Using glue is the most straightforward approach, as you would only need to apply glue to the broken area, and reattach the part accordingly.

How to use plastic patch on boat?

Commonly used in boats like kayaks, along with plastic barrels or tubs, plastic patches act somewhat like a bandage that can cover a surface that has holes or cracks. Using plastic patches requires one to heat the patches in order to soften them up for application. Once applied, it only needs time to cool down to stick on the broken surface, and the repair is done. It is worth noting that this method uses heating materials that can be dangerous if not used properly and that the same kind of plastic must be used to ensure that the patch would stick more effectively.

What is ABS plastic?

Some of them are easier to repair than others. Many plastic parts are made from a plastic called ABS. It is a hard, somewhat brittle plastic and is easily broken. Small pieces with clean breaks can often be super-glued much like reattaching a handle to a tea cup.

How to make a face with glue?

It has a limit to how much glue it can apply at once, so get the most you can out by getting it fully hot. Start by applying glue along the edges. Next, apply glue across the face. It will self-level pretty well at this stage. I filmed a short video of the process here.

Can plastic be used to make things?

It is a very useful plastic on its own and can be used to make all kinds of things. Don't be afraid to experiment. In this instructable, I will demonstrate how to not only repair a broken piece of plastic, but even to do some rudimentary molding to fabricate plastic parts.

Is hot melt glue a plastic?

For larger pieces or for more extensive repair, hot melt adhesive can be used. Hot melt adhesive or simply hot glue is really a plastic. It is very sticky when molten and is called an adhesive for that reason. It is specially formulated for adhesion. Nevertheless, it is still just another kind of plastic.

How to join plastic pieces together?

Gather materials. Get together all the plastic pieces you want to join. You’ll also need and your adhesive, of course, tissue paper, something to protect your work area, and sandpaper (for bonding smooth surfaces). Stay safe. Work in a well-ventilated, protected area.

How to remove uncured adhesive?

If you need to clean up larger quantities of uncured adhesive, moisten it and let it cure before carefully scraping it off. You can cut away cured adhesive with a sharp blade and remove it with acetone or boiling water.

What adhesives can be used to bond plastic?

Some products are better suited for large projects, while others can bond only certain kinds of plastic. Some adhesives, such as Loctite Plastic s Bonding System, are formulated to bond difficult materials like polyethylene, polypropylene, and Teflon.

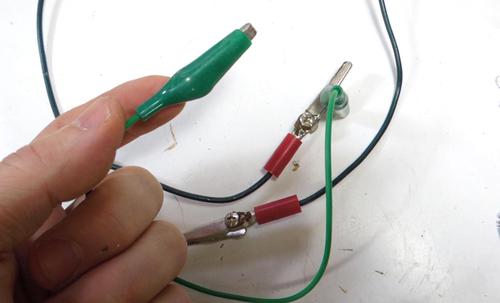

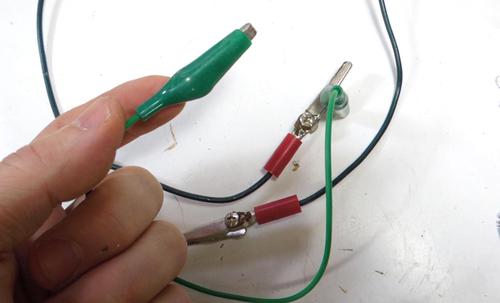

How to melt plastic in a joint?

This is how I do it: insert the iron in the joint with its flat tip line crossing the joint. push it forward a little bit, to form a small plastic mass along the joint.

What do you need to seal plastic?

If your plastic is thin, missing a piece, needs to be sealed for liquid, or under tension, you may also need: Disposable plastic strips. Staple or wire. Instant glue, soldering arms or other way to keep parts in place that you are welding.

How to make solder stronger?

Adding metal. As I've written: add a metal part can make the soldering stronger. I've already used it in buckets (people are never careful with them) and many other fixings. You need to put the metal, let's say a staple, crossing the soldering line and press it with the iron until it enters the plastic by melting it.

Can plastic break easily?

I'll explain better in further steps. Note: some plastic are already in a decomposition state, they break quite easily, almost crumbling by itself.

Can you put plastic over solder?

You can put a plastic strip over the piece to be fixed and weld them together with the iron coming from above the strip until it melts. You need to feel when the plastic below starts to melt. If it doesn't melt at all, then the soldering will be bad and the parts tend to separate after sometime.