How to Repair a Flat Ribbon Cable

- Cut the ribbon cable about 1/2-inch from the end that needs repair, making sure that the cut is clean and...

- Align the connector with the cable so that the conductor marked with a colored strip on the ribbon cable is...

- Crimp the connector onto the cable firmly and with even pressure. Inspect the connection for...

Full Answer

How to know if my ribbon cable is broken?

- A fluorescent tube back light, and an LCD filter, which filters the back light through different coloured dots as required to produce the image. ...

- An LED back light and a similar LCD filter as above

- Individual coloured LEDs for each colour in each pixel.

How to solder ribbon cable?

Soldering a ribbon cable can be somewhat tricky due to its thin individual wires. Turn the soldering iron on and set it at a temperature of 375 degrees Celsius (700 Fahrenheit). Place the connector where the ribbon cable is to be soldered on a flat and dry surface with soldering pins exposed and easily accessible.

Can You solder ribbon cable?

Soldering a ribbon cable can be somewhat tricky due to its thin individual wires. Turn the soldering iron on and set it at a temperature of 375 degrees Celsius (700 Fahrenheit). Place the connector where the ribbon cable is to be soldered on a flat and dry surface with soldering pins exposed and easily accessible.

How to repair a ribbon cable connection on consumer electronics?

How to Repair Broken or Torn Flex / Flexible Cables.

- Repairing Broken Flex Cable for Electronics Equipment. Repairing broken flexible cables, Image is oversized to show detail.

- Step 2: With Scissors cut straight the torn section completely to from two straight edges. Then follow the instructions below.

- Step 3: With Single Edge Razor Blade scrap the top side of one half of cable, expose bare copper. ...

How do you fix a ribbon cable?

1:3213:22Flexible flat cable FFC cable repair methods - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd then all you need to do is from the damaged end. Or if you can't find it damaged end or you'llMoreAnd then all you need to do is from the damaged end. Or if you can't find it damaged end or you'll get a thin piece of plastic glue it on the back at the end there to give it some stability.

Can I fix a torn ribbon cable?

In order for the ribbon to perform, each of the multiple wires inside must be fully connected along the entire length of the ribbon to the components. Easily repair a broken ribbon wire by recreating the wire connections with a metallic conductive substance.

Can you super glue ribbon cable?

The proper fix would be to replace the connector with a new one, but this requires a person with fairly good SMT skills and equipment. If you do try glue (e.g., "Superglue", or cyanoacrylate), be extremely careful to keep it away from the actual electrical contacts.

How do you reconnect a ribbon wire?

3:054:07Tutorial on How to properly connect the Flat Ribbon Cable to a 26 PIN ...YouTubeStart of suggested clipEnd of suggested clipThere both tabs are out. Now this comes very easily comes out very easily. Now again make sure theMoreThere both tabs are out. Now this comes very easily comes out very easily. Now again make sure the cable is inserted all the way in and the tabs are pushed in parallel.

How do you solder a broken flex cable?

Heat up the top foil until some of the solder paste is pull under the two layers. Then using a flat blade screw driver or razor blade hold the top layer down while sliding off the soldering iron and putting blade in it's place until solder is cooled 30 seconds.

How do you solder ribbon cable?

0:271:20Using Low Temperature Solder Paste to connect a Flat Flex CableYouTubeStart of suggested clipEnd of suggested clipThen we apply heat to the hot bed approximately 350 Fahrenheit or 10 degrees Celsius as the solderMoreThen we apply heat to the hot bed approximately 350 Fahrenheit or 10 degrees Celsius as the solder paste heats up it makes a perfect union and that's Carl's tip for a beautiful soldering.

Can you use Gorilla Glue on wires?

The Gorilla Glue Company works on most substances, including connecting wires. It is strong enough to withstand vibrations and high temperatures without losing its bond when you use it correctly.

Can I use glue instead of solder?

There is no good substitute for soldering. No glue made will conduct electricity or hold as well as solder.

Are ribbon cables replaceable?

Ribbon cables are not universal and you must purchase a replacement from the manufacturer of your TV, printer, or computer. Measure the width of the cable to determine the size you need and use the color or pattern on the cable itself to find a matching cable.

How do you splice ribbon cables?

1:053:58How To Repair Damaged Ribbon Cable (Andy's Garage: Episode - 21)YouTubeStart of suggested clipEnd of suggested clipBasically what you do is you lay the ribbon onto the track here and then you're going to go aheadMoreBasically what you do is you lay the ribbon onto the track here and then you're going to go ahead and crimp it in here to make the connection.

How do I fix the ribbon cable on my ps4?

1:292:12How to fix PS4 Controller Ribbon Cable - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd I reattached this little blue tip on the back to give it a firm backing to slide into this slotMoreAnd I reattached this little blue tip on the back to give it a firm backing to slide into this slot here and voila.

How do I know if my ribbon cable is damaged?

A lot of times in a computer you will have a screen that flickers off and on especially if you move the screen. You can pretty much bet that the ribbon cable is about ready to break. Ribbon cables don't wear out if they're not being flexed back and forth. But that's usually why there's a ribbon cable there.

How long does it take for ribbon wire to cure?

Adjust the temperature in the room where the ribbon wire is being repaired so it is no colder than 86 degrees Fahrenheit. Leave the epoxy to cure for 24 hours at this temperature.

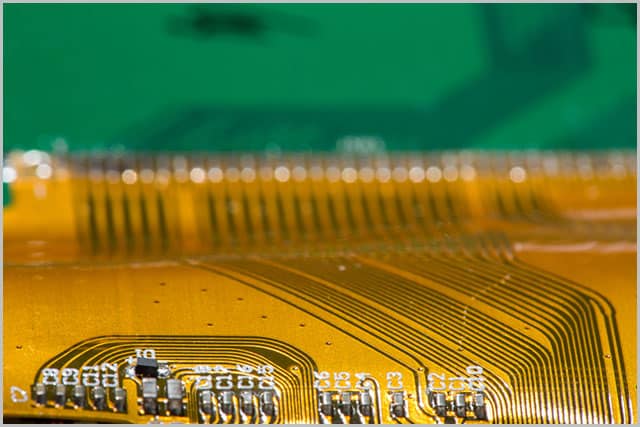

What is ribbon wire?

A ribbon wire or ribbon cable is a flat, wide strip of cable that contains multiple wires inside its insulation. If the wire becomes damaged by way of severing, the ribbon will not be able to achieve a proper connection. In order for the ribbon to perform, each of the multiple wires inside must be fully connected along the entire length ...

Step 1: Repairing Broken Flex Cable for Electronics Equipment

Images below contains all Steps and instruction to Repair Flexible Cables

Step 2

Step 2: With Scissors cut straight the torn section completely to from two straight edges.

Step 3

Step 3: With Single Edge Razor Blade scrap the top side of one half of cable, expose bare copper. Be careful not to remove copper as it may break off, Take your time! It is a slow process. Then turn over second half of cable to the back side the and scrap it to expose bare copper. About 1/8 to 3/16 inch is all that is necessary on each half.

Step 4

Step 4: With copper sides up spread a thin layer of solder paste across all exposed copper Do not worry about getting it on other parts of cable. Using a soldering iron heat the paste so it adheres to the copper part of cable. Do this to both sides.

Step 5

Step 5: Using Masking Tape, tape down securely the top exposed foil side first.They lay the copper side down half over the edge to the tape lining up as perfect as possible overlapping about 1/8 of an inch, apply masking tape as well to hold in place. Apply a small amount of solder paste at the junction of the two pieces.