Use an epoxy compound suitable for engine block repair. With the stitches in place, apply the epoxy into the crack as far as you can put it and then fill the crack completely. Cover over the surface and smooth the epoxy for a neater join.

How to repair cast iron with JB Weld?

How do you fix broken iron pieces?

- Sand the broken surfaces to remove approximately 1/4 inch of paint from both ends of the break. …

- Remove grease and dirt from the surface of the wrought iron with a clean rag dipped in mineral spirits.

- Apply the epoxy to the surface of the wrought iron and put the two pieces together.

How to repair cast iron with putty?

What You Need

- Wire brush

- Hammer

- Cold chisel

- Putty knife

- Repair paste or plumber's epoxy

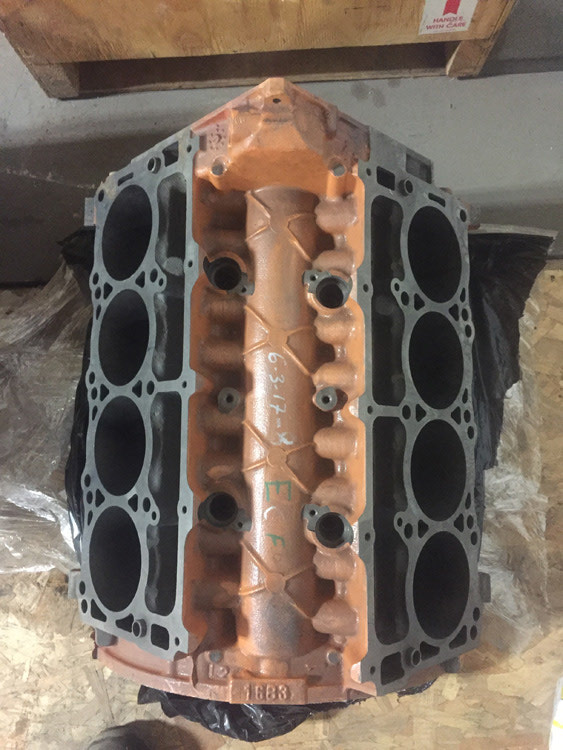

How do you repair a cracked engine block?

How to Repair a Cracked Engine Block

- Identify the crack with your three-part penetrating dye system. First, spray or paint your penetrating dye over the suspected crack and the surrounding area, then wait 5 minutes.

- Identify the three types of stitching pins in your kit. ...

- Drill a hole through the block (size recommended by the pin manufacturer) just before the crack starts.

How to fix a cracked engine block?

Symptoms Of A Cracked Engine Block

- — Overheating. When your engine block cracks, it can prevent the coolant in your car’s cooling system from circulating correctly.

- — Oil Leaks. Do you notice tiny drops of oil under your car when you park it in the driveway? ...

- — Coolant & Engine Oil Mixing. ...

- — Smoke From Under The Hood. ...

- — Poor Performance. ...

Is cast iron brittle?

Is a block worth scrap?

About this website

Can I weld a cast iron engine block?

TIG welding cast iron requires significant preheating of the area with a torch to avoid shocking the material and possibly worsening the crack. A preheat and inter-pass temperature of 500 degrees F is the minimum recommended during welding, but keep it under 1,000 degrees F.

Can a cracked engine block be fixed?

Cracked engine blocks can be repaired, but usually require replacement, either with a rebuilt engine, a new engine, or a salvage engine. While there are a number of problems that can result in a cracked engine block, most involve excess heat, which is usually caused by an issue with coolant.

Can you repair a hole in an engine block?

Depending on the size of the hole and the extent of any other damage, fixing the hole and cracking in your engine block may be possible through welding, inserting repair plugs, or other methods.

Is it possible to weld a cracked engine block?

Therefore, there are various methods of repairing cracked engine blocks: from welding and brazing, to cold metal stitching. Belzona offers a solution that does not require hot work or specialist tools.

What is the best way to fix a cracked motor block?

0:252:51Repairing Cracked Engine Blocks Without Disassembly - YouTubeYouTubeStart of suggested clipEnd of suggested clipYou can be back on the road in 20 minutes can w fiber lock is the most advanced product forMoreYou can be back on the road in 20 minutes can w fiber lock is the most advanced product for repairing crack head gaskets and engine blocks.

Can you JB weld a cracked engine block?

0:281:55Cracked Block Boat Engine Repaired With JB Weld!! TWO Year Update!YouTubeStart of suggested clipEnd of suggested clipSo i decided to get some jb weld and fix it and what i did to prep it was i got a dremel. And iMoreSo i decided to get some jb weld and fix it and what i did to prep it was i got a dremel. And i sanded that area down the crack i sanded inside it and outside it as much as i could.

How do you fix cast iron without welding?

There are several ideal methods that you could use to repair cast iron that does not require welding. Such techniques include brazing, the use of epoxy putty, and the use of cold metal stitching. What is this? It is recommended that you use ideal methods when repairing your cast iron pieces.

How do you repair cracked cast iron?

0:5810:53Tech Tips: Repairing a Crack in Cast Iron - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo when we're working on anything of a cast iron with a very high carbon content we have to startMoreSo when we're working on anything of a cast iron with a very high carbon content we have to start really following rules of welding. And not just striking an arc on the material. I have an oxy propane

Can you braze an engine block?

Cast iron is used for water pipes, machine tool castings, transmission housing, engine blocks, pistons, stove castings, etc. The metal can be brazed or bronze welded, gas and arc welded, hardened, or machined.

What do you use to weld a engine block?

4:2218:14Welding and Cast Iron Block Repair - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd you weld on cast iron with it well there's an inter-weld zone where weld metal meets base metal.MoreAnd you weld on cast iron with it well there's an inter-weld zone where weld metal meets base metal.

Can you TIG weld a cast iron engine block?

0:184:33Welding A Diesel Cast Iron Engine Block with Muggy Weld 77 Arc ...YouTubeStart of suggested clipEnd of suggested clipUsing the filler rod as a buffer between the steel and the cast iron the 77 s high elongation canMoreUsing the filler rod as a buffer between the steel and the cast iron the 77 s high elongation can stretch while heating and cooling the steel plate will be tack welded in place.

How do you braze cast iron blocks?

0:502:52How To Braze Cast Iron - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo the key to brazing is you want to get this cast iron red-hot. And then add your rod with the fluxMoreSo the key to brazing is you want to get this cast iron red-hot. And then add your rod with the flux slowly. And ideally you would like the metal to actually melt the rod not the torch.

Is cast iron brittle?

Cast iron is a fickle mistress. It's quite strong, but also quite porous and brittle. With carbon content typically in the 2 to 6 percent range, that's roughly 10 times as much as most steels. The high carbon content of cast iron causes flakes of graphite to form, which does not respond well to uneven heating.

Is a block worth scrap?

In most cases that means the block is DOA, and it's worth its weight in scrap only. Sometimes there is hope, though. It all depends on where the crack is, what caused it, and how extensive the damage. It is just metal after all, and metal can be welded.

Clean Repair Area

Thoroughly clean the repair area. Remove all dirt, grease and other contaminants.

Terminate Cracks

To terminate the cracks, drill 3/16″ (48 mm) holes at their ends to prevent further propagation.

Remove Residue

Using Belzona 9111 (Cleaner/Degreaser) remove all residue to keep the repair area free of contaminants.

Roughen Surface

Roughen the surface, and degrease the application area with Belzona 9111.

Mix Belzona 1111

Measure Belzona 1111: 3 parts Base to 1 part Solidifer by volume, and mix thoroughly.

Prepare Reinforcement

Wet out a suitable length of Belzona 9341 (Reinforcement Tape) with the mixed product.

Apply Belzona 1111

Apply a thin film of mixed product onto the prepared area, pushing the product well into the roughened profile.

How to fix a broken engine block?

Step 1 - Prepare the Block. The engine will very likely have to be removed, so be prepared to do this. It is not an easy job and it takes quite a serious amount of dismantling of parts and components to get the block out. You might also require a hoist. If the engine block is already removed you can proceed to fix it.

What happens if your engine block is cracked?

A cracked engine block might seem like an absolute disaster for your car. As the engine block is one of the most vital components of your vehicle, a damaged block can create numerous problems and consequences. If you see signs that your engine block is cracked, you have some options, so don’t worry that all is lost.

How to clean a crack in a cylinder?

The crack needs to be completely clean before you proceed any further. Use the wire brush to clean the crack and ensure there is no residue grit, grime, or dirt in and around the crack. If the crack is too wide to use the brush then just wipe it clean with a damp cloth and use a tag-rag. Even the most minute pieces of grit or dust can cause issues with the cylinders, so do not let any get inside the crack.

Is cast iron brittle?

Cast iron is a fickle mistress. It's quite strong, but also quite porous and brittle. With carbon content typically in the 2 to 6 percent range, that's roughly 10 times as much as most steels. The high carbon content of cast iron causes flakes of graphite to form, which does not respond well to uneven heating.

Is a block worth scrap?

In most cases that means the block is DOA, and it's worth its weight in scrap only. Sometimes there is hope, though. It all depends on where the crack is, what caused it, and how extensive the damage. It is just metal after all, and metal can be welded.