Stained Glass Repair (Solder Surgery)

- Remove Solder From Affected Area. Once you have identified that some of the copper foil tape has been damaged to the point it will need repair, begin by ...

- Cut a “Band-Aid” Copper Strip to Size. After removing solder from the affected area and its surrounding edges, measure the spot or line up a piece of copper ...

- Soak Copper Strip in Alcohol. ...

Full Answer

What to do if your stained glass copper foil oxidise?

Stained Glass Copper Foil Tips for Oxidised Stained Glass Copper Foil Fix problems of oxidation. A mix of vinegar and salt is an etchant! If it is not neutralized, it will continue to work forever. The metal (in this case copper) will pulverize and have holes. You should always neutralize etchants.

How to repair a broken copper foil panel?

Things You'll Need

- Replacement glass

- Paper

- Pencil

- Safety glasses

- Glass cutter

- Needlenose pliers

- Cardboard box

- Old newspaper

- Flux

- Solder

What is Tiffany copper foil method?

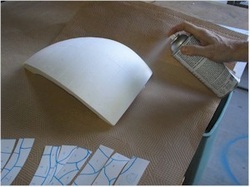

Technique 2: Machine Foiling Stained Glass

- Apply foil to each piece by pressing the edge of the glass onto the roller and roll all sides of the glass until all sides have been foiled.

- Use the fid to press the foil firmly onto the glass edges.

- Continue the process until all pieces are wrapped in the foil and you have firmly pressed the foil on the glass using a fid tool.

How to cut glass, tips for the stained glass hobbyist?

- If you are using a comfort grip/pencil grip cutter, hold it like you would hold a pencil or hold it like a pistol if you're using a pistol grip cutter. ...

- If you are using glass other than window glass, determine which side of your glass is the front. ...

- Cut slow and steady. ...

How do you fix foil on stained glass?

0:127:14How to Repair a Copper Foil Stained Glass Panel - YouTubeYouTubeStart of suggested clipEnd of suggested clipAfter you get it mostly melted off then you're gonna push the foil back off of your piece and youMoreAfter you get it mostly melted off then you're gonna push the foil back off of your piece and you just do that with your hot iron. And do that all the way around on both sides.

How do you reinforce copper foil stained glass?

6:0614:173 ways to Reinforce Stained Glass Panel using copper V141 - YouTubeYouTubeStart of suggested clipEnd of suggested clipUsing the tip of my soldering iron I pushed the copper strip over the edge which bends it holdingMoreUsing the tip of my soldering iron I pushed the copper strip over the edge which bends it holding the strip in place with needle nose pliers. I saw to the copper against the edge of the foil.

What is the best solder for copper foil stained glass?

The 60:40 solder is best suited for copper-foiled work because it stays liquid for a long time when cooling and can produce smoother and shinier beads. The 50:50 solder is a compromise if you cannot buy 40:60 solder. It is not as good as 60:40 solder for copper-foiled work because it does not stay liquid for as long.

How do you fix a broken piece of stained glass?

10:3116:38How to Repair and Replace Cracked or Broken Stained Glass - YouTubeYouTubeStart of suggested clipEnd of suggested clipYou glue this onto your glass. Cut it grind it but before you foil it make sure that you put it backMoreYou glue this onto your glass. Cut it grind it but before you foil it make sure that you put it back in your window because on edge pieces like this notoriously.

Can copper foiled stained glass go outside?

When you copper foil stained glass it's best to start foiling away from the outside edge as this makes for stronger adhesion. This is because the foil isn't joined on the outside edge where is is more likely to come loose.

How do you make stained glass sturdy?

Metal Rods They are drilled and fixed into the window frame and copper ties soldered on the stained glass are twisted around it. Alternatively Flat Rebar are flat metal rods which are soldered on to the face of the came in place on the inside of the panel to keep the entire work from flexing.

Can you solder copper foil?

11:3612:58Tips on Soldering Copper Foil - YouTubeYouTubeStart of suggested clipEnd of suggested clipWe step forward and put another little drop down and that drop melts back into the previous one andMoreWe step forward and put another little drop down and that drop melts back into the previous one and seems up we put just enough solder on. So it will beat up and hang over the edges of the foil.

Can I use electrical solder for stained glass?

We often get asked why the solder at the hardware store cannot be used in stained glass. The solder stained glass stores sell is different than common solder you might find in your garage or at the hardware store. Normally that solder is rosin core or acid core solder. If you use these you will end up with a scum mess.

Do you need flux to solder stained glass?

Solder will not stick to glass alone, so each piece of glass must be wrapped in copper foil. 3. Solder needs a flux to flow smoothly and bond to other metals (i.e., copper foil or lead came).

Can you glue broken stained glass?

Remove the damaged piece and replace it (some soldering skill is required). Glue the cracked glass together using a variety of adhesives. Cover the crack with adhesive tape to match the lead came.

How do you reinforce glass?

Window Protection Film: 5 Solutions to Reinforce Glass Windows &...3M™ Scotchshield™ Safety & Security Window Films. ... 3M™ Impact Protection Attachment Systems. ... DefenseLite™ Forced Entry Glazing Solution. ... BulletShield™ Ballistic Panel. ... 3M™ Anti-Graffiti Films.

What is Restrip for stained glass?

Reinforce Your Stained Glass Project Like a Pro Re-Strip is a rigid ribbon like strip of 10 mm thick copper that is used between glass pieces as hidden structural reinforcement. To use, insert into lead came channel or solder between foiled panels.

How do you use copper foil?

2:328:16Copper Foiling Glass Pieces for Stained Glass - YouTubeYouTubeStart of suggested clipEnd of suggested clipI usually start right as I'm about to do one whole entire side so I've got a little bit of somethingMoreI usually start right as I'm about to do one whole entire side so I've got a little bit of something to hold on to I hold the piece on its edges as opposed to the sides.

How do you use Morton's strong line?

The Strong Line is placed in lead channel during assembly. The panel must then be cemented to add strength and prevent the Strong Line from twisting in the channel. Strip is placed between foiled glass pieces before soldering. Once soldered on both sides of the panel the steel strip cannot be seen.

How to repair copper foil?

I will show you my favorite (and easiest) way first. You'll need an aluminum soda or beer can. Cut the top off, then make a cut from top to bottom, and cut off the bottom.

How to fix broken copper foil?

When you are repairing copper foil that can't be done using aluninum strips, remove as much solder as possible around the broken piece. Then you will score the broken piece of glass, many times, in all directions (horizontal, vertical and diagonal). Turn the panel over and hold it over something to catch the broken glass as it flies out. A large waste basket or a box will work.

How to get foil off a soldering iron?

Grab the foil with your pliers and pull the foil off as you go ahead of it with your soldering iron. Most times the foil comes off in one piece, but there are times when you get it off little by little. Once the foil is off, run your soldering iron around the opening to clean up any remaining solder.

How to fix a split in solder?

The split will still be visible. You're going to have to fix it before you start soldering. Make sure the area around the split is clean. To be sure, go over the split with alcohol. Take a short piece of foil and wrap it, front to back, over the area where the split is.

Can you cut aluminum foil with scissors?

Ordinary scissors cut the aluminum very well, but don't use your best scissors, as the aluminum will dull them. These aluminum strips are handy for repairing copper foil, so I always have a few of them stored with my foiling tools. Plug in your soldering iron.

Can you use aluminum strips to repair copper foil?

However, there will be times when you can not get the aluminum strip between the glass. It just won't go through. In that case, you will have to use my other method to repair copper foil.

Can you fix copper foil?

When you are repairing copper foil, it's important to make sure the glass is squeaky clean before you start to apply the foil. If there is any oily residue left on it, the foil won't stick to the glass. Replace the foil, and solder the piece back in place.

What happens if you don't centre copper foil?

If you don’t centre the copper foil properly on the edge of the glass, you get a very thin strip of foil on one side and a a very thick strip on the other. This is particularly annoying with transparent glass because you can see the other side of the foil. [00:33]

How to fix a curved glass?

to fix it, use the exact same principle as with the circle above but because it’s a much tighter curve, make smaller increments with the craft knife. move your fingers around a tiny little bit at a time. you can also move the glass rather than the blade for these tiny adjustments.

Does solder stick to stained glass?

This IS a little bit fiddly to do but because the solder only sticks to the foil, the more accurate and the neater your stained glass foiling is, the better your soldering lines and your end result will be.

How to solder copper foil?

Try the following on your oxidised stained glass copper foil and see the magic for yourself: 1 mix a quarter cup of white vinegar and a quarter teaspoon of table salt until the salt dissolves 2 dip the pieces of foiled glass into the mixture and swirl it around for about 30 seconds 3 rinse the pieces with water and dry them 4 that’s it! They are now ready to solder together

How to make oxidized glass foil?

Try the following on your oxidised stained glass copper foil and see the magic for yourself: mix a quarter cup of white vinegar and a quarter teaspoon of table salt until the salt dissolves. dip the pieces of foiled glass into the mixture and swirl it around for about 30 seconds.

How to clean flux after soldering?

Dawn) with one of those green pan scrubbers until it froths up. Dry thoroughly with a paper or lint-free towel. Or you can use Kwik Clean to clean off the flux.

Why does copper foil not stick to stained glass?

Why does the copper foil not stick when applying it to stained glass? There are generally 4 reasons that this will happen: The glass is dusty or oily which prevents proper adhesion of the foil. Your fingers are all over the foil when applying it. The foil might be old or it’s just a bad batch.

Do you need to scrub glass?

Some say that you need to scrub the glass with all sorts of cleaning products. Others say to use them in a certain order to ensure proper adhesion of the foil.

How to make a glass holder with copper foil?

Start by peeling back a section of the paper to expose the adhesive on the copper foil. Hold the foil strip in your dominant hand and the glass piece in the other. Now you can start by attaching the copper foil making sure the glass is centered onto the foil.

How to clean glassware?

To wash the pieces, fill a small basin with water with a couple tablespoons of ammonia then dip the pieces in the solution. After a quick dunk, dry them thoroughly with a clean lint-free towel. Be sure to clean all edges and surfaces of each piece. Be sure to dry the glass completely before moving on.

What is the difference between copper foil and lead came?

The major difference between the two methods is found in the assembly. The copper foil technique is perfect for beginners as it is easier to get started with and will work with most stained glass projects. Lead came requires fitting the glass pieces into lead channels called cames, which is then soldered at the joints and cemented.

How does a foiling machine work?

The machine will simultaneously pull the backing off of the foil, center the glass onto the foil, and fold the sides down the edges as you slide the glass edges along the roller.

Can you clean solder joints?

Now that you have completed all of your soldering you can clean your piece and put the finishing touches on it. It is important to wash the glass and newly soldered joints really well if you intend on applying a patina to the solder.

Do you need gaps in solder joints?

Ideally, you do not want any gaps and if there are they should be minimal. Gaps can compromise the strength of the solder joint as well as use more solder than necessary since you will have to fill the gap with solder to connect the two pieces. Another method is to use something like a reinforcement strip.

Can you assemble stained glass?

After you have made all of the cuts for your pattern it is a good idea to assemble st ained glass pieces into the pattern you have chosen to ensure a good fit between each piece. If any of the edges between pieces aren’t fitting together nicely or there is too much space between the pieces you will need to correct this.