Full Answer

How to repair rust and Weld body panels?

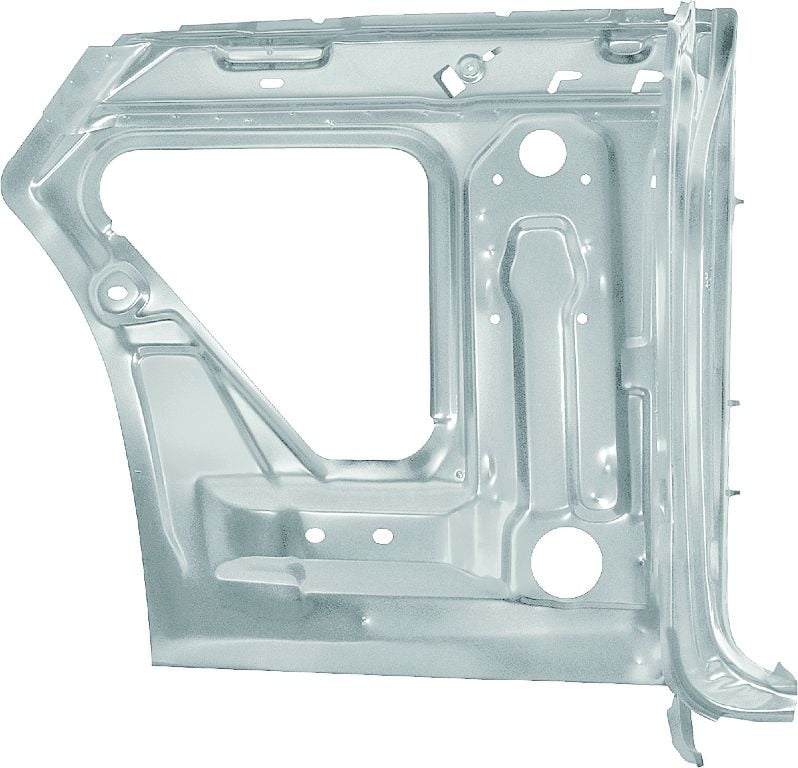

There are several factors to consider when determining whether to repair or replace a damaged panel:

- – Extent of damage

- – Availability of replacement panels

- – Cost of replacement panels

- – Quality of replacement panels

- – Difficulty to repair vs. replace

How do you repair rusted panels?

Tools Required for a Slip-On Rocker Panel Replacement

- A wire brush

- A pneumatic/electric drill

- Angle grinder

- A hammer or a pry bar

- Rivets/fasteners/glue

- Anti-rust agents

Can You glue on body panels?

“You can apply adhesive anywhere there is structural joining with a weld or rivet,” he says. Use it on the body-in-white. Use it on closure panels. And what is notable is that it can be used to join multiple materials: steel, aluminum, magnesium, composites, plastics, glass.

Can I use body filler on aluminum?

Aluminum auto body filler does not corrode and sticks well to galvanized aluminum and steel. To use this auto body filler, you must clean the surface of any wax or greasy buildup, mix filler with liquid hardener to room temperature, and stir it.

Can aluminum Corrosion be repaired?

All aluminum needs to corrode is water, oxygen, and time just like any other reactive metal no different than iron and steel. The best we can do for corroded aluminum is to remove the oxidation and seal it from moisture with a plastic coating.

How do you repair aluminum body panels?

1:0514:23Repairing Aluminum Body Panels With Collision Damage - YouTubeYouTubeStart of suggested clipEnd of suggested clipTo help out you know the technicians aren't how to actually repair. These these aluminum panels allMoreTo help out you know the technicians aren't how to actually repair. These these aluminum panels all right well let's get to it today I kind of want to make sure we cover a little bit of the basics.

Can I use body filler on aluminum?

Aluminum auto body filler does not corrode and sticks well to galvanized aluminum and steel. While it performs metal with metal repair, it still lets you work on the overhaul like any premium body filler.

How do you repair damaged aluminum?

4:366:09How To EASILY Repair Holes In Aluminum - YouTubeYouTubeStart of suggested clipEnd of suggested clipWhat you're going to do is as you heat up the aluminum. The brick the fire brick is going to beMoreWhat you're going to do is as you heat up the aluminum. The brick the fire brick is going to be right against the metal nice and tight you're going to take the filler rod.

What is the best body filler for aluminum?

The Ease of Bondo® Filler, With Extra Strength This simple 2-part filler is reinforced with aluminum — great for use on fiberglass, metal, aluminum and even wood or masonry. Metal Reinforced Filler includes a small tube of hardener.

What JB Weld is best for aluminum?

For a reliable aluminum epoxy that can handle medium- to heavy-duty jobs, the J-B Weld KwikWeld epoxy has a 5,020 PSI rating and withstands temperatures of over 500 degrees Fahrenheit, making it an ideal option for cars, RVs, and boats.

Can you use epoxy primer on aluminum?

Epoxy primers are used on virtually all substrates including aluminum, steel, stainless steel and more.

How do you prepare aluminum for body filler?

0:062:41PPG's Top Tips for Metal Surface Prep of Bare Aluminum - YouTubeYouTubeStart of suggested clipEnd of suggested clipBegin by cleaning the entire part using a regionally compliant solvent-based wax and grease remover.MoreBegin by cleaning the entire part using a regionally compliant solvent-based wax and grease remover. And a clean towel. Then dry the part thoroughly.

Will Bondo stick to aluminum siding?

Yes, you can use Bondo (or any other body filler) to fix your RV aluminium siding. Bondo is a two-part resin originally formulated for auto-body repairs, including damaged aluminium.

Can Ford aluminum body be repaired?

Minor damage on an aluminum panel can be easily repaired with backside access, but if the damage is on a body line or crown, the repair may not be possible.

How can I join aluminium without welding?

0:482:16How to "Weld" Aluminum Without a Welder - YouTubeYouTubeStart of suggested clipEnd of suggested clipYou'll know when it's hot enough when the rod starts to melt on. Contact rub the brazing rod alongMoreYou'll know when it's hot enough when the rod starts to melt on. Contact rub the brazing rod along the channel until it's filled in and finish it off with some more. Heat.

How do you weld aluminum body panels?

12:4616:33Welding Aluminum Body Panels | Boat-tail Speedster Pt. 26 - YouTubeYouTubeStart of suggested clipEnd of suggested clipBut what I did was I tack welded it in inch apart. Along the whole seam. And then when I went toMoreBut what I did was I tack welded it in inch apart. Along the whole seam. And then when I went to weld it I would weld an inch at a time and let it cool completely in between each inch of wealth.

How do you weld aluminum body panels?

12:4616:33Welding Aluminum Body Panels | Boat-tail Speedster Pt. 26 - YouTubeYouTubeStart of suggested clipEnd of suggested clipBut what I did was I tack welded it in inch apart. Along the whole seam. And then when I went toMoreBut what I did was I tack welded it in inch apart. Along the whole seam. And then when I went to weld it I would weld an inch at a time and let it cool completely in between each inch of wealth.

Can Ford aluminum body be repaired?

Minor damage on an aluminum panel can be easily repaired with backside access, but if the damage is on a body line or crown, the repair may not be possible.

How do you prepare aluminum for body filler?

0:062:41PPG's Top Tips for Metal Surface Prep of Bare Aluminum - YouTubeYouTubeStart of suggested clipEnd of suggested clipBegin by cleaning the entire part using a regionally compliant solvent-based wax and grease remover.MoreBegin by cleaning the entire part using a regionally compliant solvent-based wax and grease remover. And a clean towel. Then dry the part thoroughly.

How do you fill dents in aluminium?

On the bright side, aluminum dents and dings are easily repaired without the tools or skills of an experienced technician.Drill a Hole In It. Drill a small hole in the center of the dent. ... Insert a Sheet Metal Screw. ... Tug The Washer. ... Putty the Hole. ... Sand the Spot. ... Prime and Paint the Repair.

Working With Aluminum

Repairing aluminum body panels can be quite different than repairing steel.

Aluminum Repair Resources

When working on aluminum, it’s best to have the latest information. That’s where Toyota’s Technical Information System (TIS) comes in handy. Go on TIS and enter the specific information for the vehicle you’re repairing and look under the Collision Repair folder.

Aluminum and Automobiles

Aluminum and steel are two distinctly different metals. Here’s a chart to help you know some of their differences.*

Repair Procedures

First and foremost, be advised that various OEMs have different rules/repair procedures when working with aluminum. Just because you’re trained or certified with a particular OEM does not mean those same considerations can cross over to another automaker. While this can be frustrating, it’s important to note this current inter-industry reality.

Different Grades

Aluminum, like steel, has different grades and characteristics that determine strength and repairability. Aluminum is graded in seven different series, so knowing what series you’re working with is important when determining repair plans and procedures.

Corrosion

When working with aluminum, things to consider during repairs are galvanic corrosion and cross contamination. It’s critical to keep steel and aluminum parts separated during a repair to avoid any particulate contact between an exposed bare metal body panel in the surrounding area.

Glue Pulling

When repairing dents on an aluminum panel, my first choice of repair method is the use of glue-on pull tabs. If this doesn’t work, I suggest using paintless dent repair (PDR) theory and methods.

Separate Tools

Along with a designated space/area, aluminum dust extractors and separate welding equipment, you must also have a separate set of hand and power tools to avoid cross contamination, including but not limited to different gloves, sandpaper, saw blades, grinders and grinding discs.

Structural Realignment

The most important topic regarding aluminum currently is structural realignment. Should any aluminum structural part on an aluminum vehicle or mixed-material structure be pulled out on a frame machine? As a trained certified aluminum structural technician, my answer to that question is unanchored pulling only, using only the weight of the vehicle.

What happens when you scratch aluminum oxide?

Aluminum Corrosion. Scratching this oxide skin exposes bare metal, and the process begins again. It won’t eat the metal away though, except under two conditions. First, if chlorides or sulfides are around they’ll attack the aluminum oxide layer. Chlorides are compounds of chlorine.

Why does aluminum oxidize faster than steel?

Aluminum oxidation happens faster than that of steel, because aluminum has a really strong affinity for oxygen. Rather than flaking though, aluminum oxide just forms a hard, whitish-colored surface skin. When all the aluminum atoms have bonded with oxygen the oxidation process stops.

What is rusting metal?

Rusting is a specialized form of corrosion that only iron and steel go through. Rust is when the iron oxidizes and flakes off. It’s accelerated by moisture. Flaking exposes fresh metal beneath, which in turn oxidizes and flakes. Aluminum oxidation happens faster than that of steel, because aluminum has a really strong affinity for oxygen.

What is galvanic corrosion?

this is an electrical effect experienced when dissimilar metals are brought close together in a conducting liquid. For example, immerse brass and aluminum in seawater and electrons move from the aluminum to the brass. This can be a problem in boats where brass fittings are ...

What is the difference between rust and corrosion?

(Gold is one notable exception.) Corrosion starts with oxidation, where atoms of metal link up with oxygen, followed by a gradual , or not so gradual , breakdown. Rusting is a specialized form of corrosion that only iron and steel go through.

Which is better, aluminum or aluminum?

Spend too long in damp environments and you’ll find reddish brown flakes lifting off the surface. Aluminum would be better because its much lighter and doesn’t rust. Aluminum does corrode though, especially if exposed to seawater.

Is anodizing a good finish?

Anodizing is a kind of surface oxidation that can produce some very attractive finishes. However, it’s not usually practical for larger fabrications. If taking the coating approach, don’t forget that any damage needs immediate attention. Leave some aluminum exposed and you risk corrosion getting a toehold.