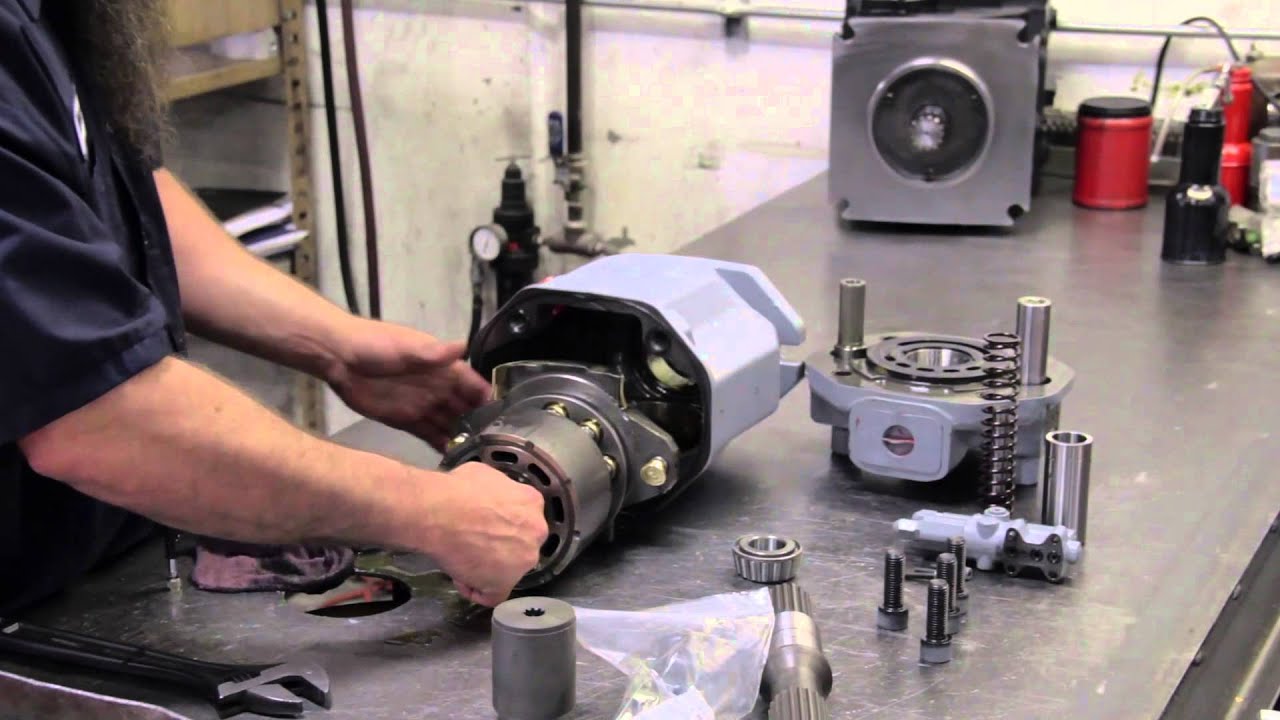

The repair process typically proceeds as follows:

- Complete corrosion removal and cleaning of the affected part or item. Choose a corrosion removal process that will not cause further damage to the item for repair. ...

- Determine and apply the most suitable repair process. ...

- Final surface treatment or protective coating.

- Inspection and testing.

How to remove corrosion at home?

soaking in lemon or lime juice (to remove traces of corrosion more effectively, you can sprinkle the metal surface with table salt, rinse with lemon or lime juice, and leave for a long time; afterwards, as is the case with vinegar, rub the rust off with crumpled foil);

How do you clean corrosion?

Will dirty battery terminals symptoms?

- Your car’s interior lighting dims.

- Your engine is slow to crank.

- Your engine fails to start.

- You hear a clicking noise when you turn the key, but the engine won’t start.

- Your car has lost electricity.

- Your engine stalls if you don’t get your car moving.

How to clean off corrosion?

- Spread the paste over the rust-stained area and leave it to harden. When it does, use a metal tool to scrape it off.

- If the stain has not been fully removed, use the same method and apply the paste again.

- Go over it as much as you can to get it off.

What removes corrosion from metal?

These films can be obtained by the following methods:

- nitrogenation – saturating the metallic surface with nitrogen;

- oxidation – creating durable oxide films (for example, Al2O₃, BeO);

- phosphatizing – creating a phosphate protective film (such as Fe₃ (PO₄)₂).

How do you treat corrosion?

5 Different Types of Corrosion Prevention MethodsBARRIER COATINGS. One of the easiest and cheapest ways to prevent corrosion is to use barrier coatings like paint, plastic, or powder. ... HOT-DIP GALVANIZATION. ... ALLOYED STEEL (STAINLESS) ... CATHODIC PROTECTION. ... EONCOAT – A NEW WAY TO PROTECT ASSETS FROM CORROSION.

How do you fix corrosion on steel?

Epoxy – For smaller steel sections, an effective and handy approach to repairing steel is by using epoxy specialized in reconnecting and reinforcing broken and cracked steel sections. The procedure is done by creating the epoxy mixture, which then leads to the application of the epoxy into the damaged section.

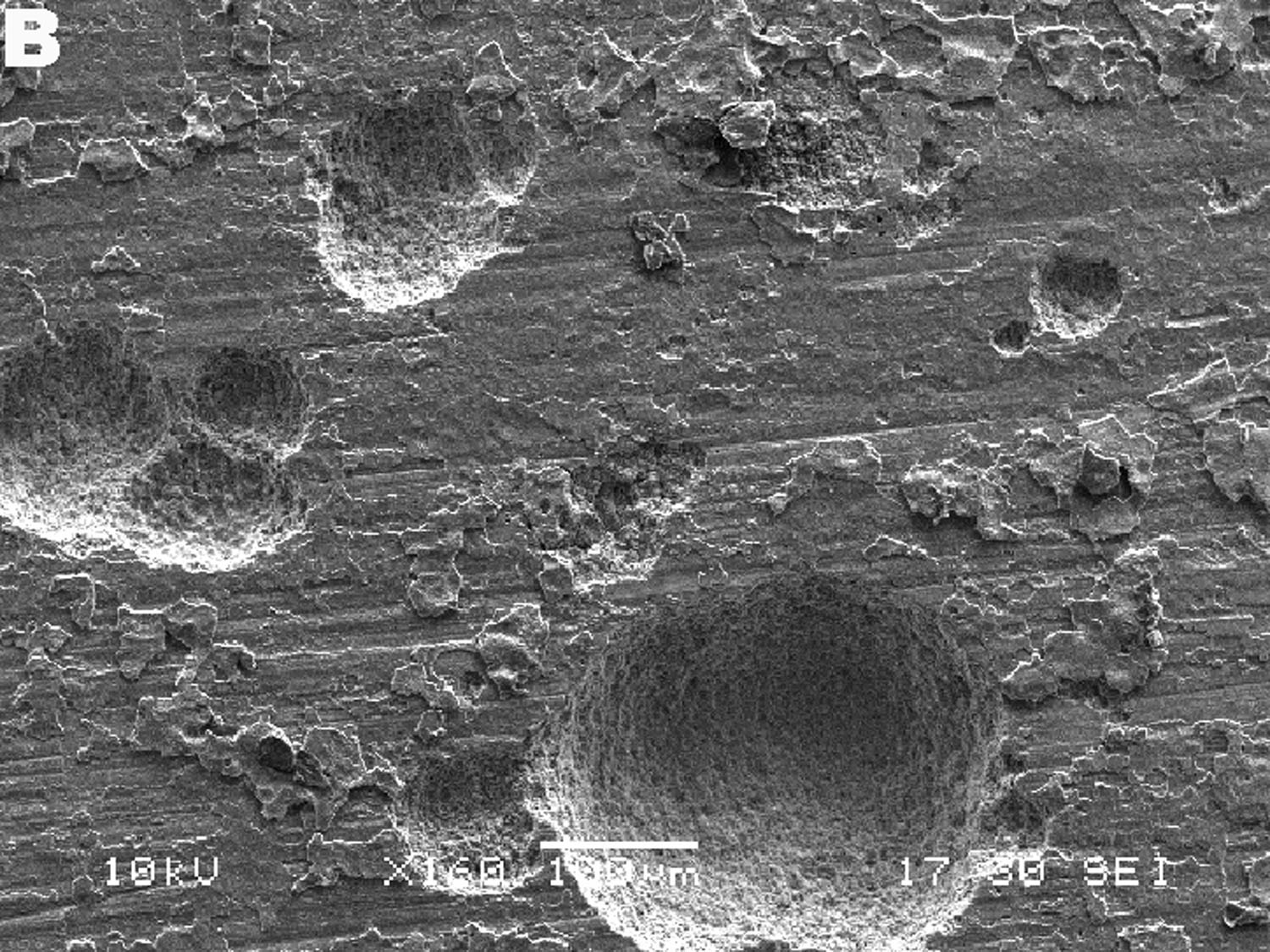

Can pitting corrosion be repaired?

Pitting Repairs: Welding Localized corrosion in the form of deep pits can be repaired by welding to restore the original profile; however, sufficient expertise and special tools are required.

What are the 3 main causes of corrosion?

3 causes of corrosion you should probably know all aboutFrom vehicles to metal tools, machinery to gutters of our homes, you will find corrosion everywhere. Corrosion and rust is the result of aging metals. ... Regions. Your metal objects will corrode faster if you live in coastal regions. ... Neglect.

Can corroded metal be fixed?

In short, yes! That old wrought iron fence or steel gutter may look terrible, but with the right preparation and primer, most rusty metal surfaces can be restored to almost new. The first step is to clean off loose rust and flaking paint and then apply a rust-inhibitive primer.

How do you repair damaged metal?

Epoxy or Tape Epoxy and tape are two common no-weld hole repair options. These do-it-yourself approaches are effective when repairing a small hole rather than a significant tear. Specialty epoxy and tape products are designed to patch steel and metal.

How do you remove deep pitted rust?

How to Fix Pitting in Metal Before PaintingWrap a sheet of 80-grit sandpaper around a sanding block and sand the pitted area aggressively. ... Wipe the sanding dust off the metal with a rag.Scrub the metal with a wire brush to remove rust particles from inside the pits and wipe off the particles with a dry rag.More items...

How do you fix pitted corrosion?

If a component is still structurally sound, pitting corrosion can be mechanically removed by grinding or polishing and the missing metal replaced by weld build-up. Care must be taken to prepare and undertake the welding process carefully, to avoid reducing the properties of the surrounding metal.

Can pitting corrosion be stopped?

Pitting corrosion can be controlled by: Use of a coating that will prevent pitting on metal surfaces. Using more corrosion resistant materials.

What is the difference between rust and corrosion?

Corrosion is the process by which certain materials, metals and non-metals, deteriorate as a result of oxidation. Rusting is oxidation of iron in the presence of air and moisture. Corrosion can occur on materials such as ceramics or polymers. Rusting occurs on surfaces of iron and its alloys.

How do you prevent corrosion?

How to Prevent CorrosionUse non-corrosive metals, such as stainless steel or aluminium.Make sure the metal surface stays clean and dry.Use drying agents.Use a coating or barrier product such as grease, oil, paint or carbon fibre coating.Lay a layer of backfill, for example limestone, with underground piping.More items...

What is corrosion how can it be prevented?

When some metals are exposed to moisture, acids etc., they tarnish due to the formation of respective metal oxide on their surface. This process is called corrosion. Corrosion can be prevented by painting the surface, oiling, greasing, galvanizing, chrome plating or making alloys.

How do you reverse oxidation of metal?

Best Rust Remover for Metal To play it safe, combine baking soda with water to form a paste and apply it to the rust; remove it carefully with a fine sandpaper or a cloth. White vinegar may also work. Either rub it onto the metal with a cloth or soak the item if it is smaller.

How do you remove white corrosion from metal?

There are various methods to remove white rust and repair damage, depending on the severity of the oxide coating. Two methods are shown: rubbing with a nylon scourer (scotch-brite) and vinegar; and mechanical buffing with a wire brush wheel.

What is corrosion repair?

Definition - What does Corrosion Repair mean? Corrosion repair is the process of fixing, restoring or rebuilding something that has deteriorated into a defective, damaged or inferior condition because of corrosion.

What are the signs of corrosion?

Pitting and flaking of metal and paint are some of the early signs of corrosion. The corrosion repair process varies according to the type of corrosion and other factors.

What is the gradual destruction and degradation of materials through chemical and/or electrochemical reaction with their environment?

Corrosion is the gradual destruction and degradation of materials through chemical and/or electrochemical reaction with their environment.

Is corrosion a problem?

Corrosion is a dangerous and extremely costly problem across a wide range of industries . In the most serious of cases, it can cause buildings and bridges to collapse, oil pipelines to break and chemical plants to leak.

What is the best way to repair broken steel?

Depending on the situation, here are some effective repair methods you should try out: Welding – The most basic form of repairing steel, welding is the simplest and most practical approach, as the goal is to reattach broken steel sections together by welding them again.

How to protect steel from rust?

A good preventive measure that can help protect your steel sections and parts from rust is by applying protective coatings such as rust-resistant paint or solutions. These solutions help add an extra layer that provides extra protection against elements that cause rust, prolonging the life of your steel parts and sections.

Why is steel corroded in the Philippines?

While steel remains as one of the most durable materials used in construction, there are times that steel products in the Philippines can also get damaged or corroded due to a number of factors, such as wear and tear and exposure to various substances. Should this happen to the steel ...

What does it mean when steel is broken?

Broken Steel. Broken steel can refer to steel that has cracked, or has completely broken off. Both pose safety and structural hazards that can compromise the whole structure. There are a number of ways to repair these issues, all of which provide a proper fix with the right application.

Can steel be repaired?

By following these repair processes and safety procedures, you would be able to repair your steel structures in no time.

Can corroded steel be repaired?

Along with broken steel sections, corroded steel is also a situation that poses a number of safety hazards that would compromise your steel structure. Rust can not only ruin the surface of your steel but it can also weaken it, leading to cracks and broken sections that need to be repaired immediately.

How to repair corrosion in pipes?

While your pipes may have already have corrosion, you can still repair them in several ways. You will need to determine the cause of corrosion in your pipes. Items like water chemistry vary from one geographic region or from one water source to the next. The design of piping systems varies from building to building. You will need to determine water velocity, water temperature, and even the metallurgy of the piping. The more traditional methods of how to repair pipe corrosion include the following: 1 Chemical flushing of the system 2 Spot repairing and replacement 3 Redesigning your hot water re-circulation system to keep your water velocity below 4 feet a second for temperatures up to 140 degrees F, if above 140 F flow maximum recommendations are to not go past 3 feet per second 4 Remove abrupt changes in piping direction 5 De-burr all tube ends before joining 6 Ensure all proper soldering joints 7 Ensure there are no dissimilar metals or make sure they are isolated 8 Spot repair leaks using gear clamps or other temporary devices 9 Use a water treatment system to adjust water quality and pH levels 10 A drastic measure is to re-pipe the whole building or part that has corrosion

What causes corrosion in copper pipes?

Water Acidity. Abnormal pH scales in your local water that is running through your piping is a common issue that causes corrosion. The pH scales ranges from zero (extremely high acidity) to 14 (extremely high alkalinity); the middle of the scale, 7, is the neutral point. In copper piping low pH will eat away at your pipes slowly.

How does oxygen degrade metals?

Oxygen degrades metals through a chemical process known as oxidation. This causes metal converting to an oxide that is also known as rust. As the pipe corrodes, the impurities deposit in the water lines, causing encrustation and buildup of minerals.

When joining metals together that aren't similar in composition, they start to undergo a galvanic answer

When joining metals together that aren’t similar in composition, they start to undergo a galvanic corrosion. While touching, conflicting metals start to give up electrons. Basically, at the point of contact (pipes threaded together) the metal that is giving up electrons will dissolve over time. The most common occurrence ...

Is oxygen in water corrosive?

Dissolved air in water consists of abut 30% oxygen and the rest is mostly nitrogen, which isn’t corrosive.

Can dielectric fittings be used to stop galvanic corrosion?

The use of dielectric fittings helps stop the problem. However, they don’t repair the resulting thin walled and damaged pipe.

What is the best tool to test for corrosion?

The tool you choose may depend on requirements you are given, ease of use, or simply preference. At the end of the day, iCOR and XCell are both excellent choices to accurately understand and assess corrosion.

What are the elements that can penetrate concrete?

Concrete structures can be exposed to elements like salt water, CO2 and chloride, which can penetrate the concrete all the way to the steel reinforcement, resulting in corrosion. If corrosion is not properly monitored and managed, the durability of the structure begins to weaken, which has serious safety risks.

Can you see cracks in concrete?

While you can see and solve non-structural cracks simply by looking at the concrete, it can be difficult to ensure that there is, in fact, no structural damage occurring. Further, there may be underlying issues that can go completely unnoticed. Therefore, it is important to properly test either the corrosion potentials or the corrosion rate ...

Is it too late to repair a crack?

Often, if you see corrosion, it is too late for simple repairs, and rebuilding may be necessary. However, sometimes non-structural cracks may appear, which may not pose any safety risks at first. Although not immediately dangerous, there are a couple of reasons you might want to repair these cracks.

Can ICor perform a half cell potential test?

It can perform all of these functions with no connection to reinforcement, but by adding this connection iCOR is also capable of performing the half-cell potential test. Both iCOR and XCell can help you identify corrosion, which is critical to know before beginning concrete repair.

How to repair rust spots on metal?

Sand through the rust spots down to the bare metal, using 40-grit sandpaper. Enlarge the sanded area so you'll have space to feather the edges. Switch to 120-grit sandpaper to feather the edges of the repair area. Complete the feathering with 220 grit. Use a tack rag to remove particles from the unmasked area. Step 4.

How to fill pits in metal?

If the rust has created pits in the metal, you can fill them now with body fill er or wait until the epoxy primer dries and apply multiple coats of filler primer. Clean the entire unmasked area with a grease-cutting dishwashing detergent, followed by clean rinse water. Let it dry.

How long does it take for epoxy primer to dry?

Apply two to three heavier coats of lacquer filler primer, allowing drying time between each coat. Let the lacquer primer dry until it's dry to the touch—at least one hour—before sanding.

How long to let clear coat dry before buffing?

Let the clear coat dry for several hours before driving the vehicle and at least 48 hours before buffing. Using an old cotton T-shirt or microfiber cloth and buffing compound, hand-buff the repaired area.

Can you use a spray gun to fix scratches?

Pro tip: Even if you know how to use a spray gun, mixing automotive paint with a reducer to match the temperature and humidity conditions can be mighty tricky. We don't recommend it. Instead, buy aerosol cans for larger repairs and rollerball applicators to fix scratches.

Is it hard to fix rust on a car?

However, if you deal with rust early, you can stop it from spreading and squeeze a few extra years out of your vehicle. Rust repair isn’t hard, but it is time-consuming (mostly waiting for primer and paint to dry between steps). Plan to spend about $100 on supplies like sandpaper, primer, ...