Can die cast metal be repaired?

Metal glue works well for diecast repairs because the adhesive specifically works on metal surfaces. As metal glue is typically gray and resembles the natural color of the metal, so use the glue only on diecast pieces without any bright colors or high levels of decoration.

Can diecast metal be soldered?

Depends on the die-cast metal grade and type, but assuming Mazak, or Zamak, (zamac), then, yes, it will solder with ordinary tin lead solder, and an acid flux. But, most people have really extreme difficulty getting it to work, because not enough heat is used, and not the right type of flux.

How do I join diecast metal?

2:314:24Pot Metal and Zinc Die Cast Repairs Made Easy With Super Alloy 1 Multi ...YouTubeStart of suggested clipEnd of suggested clipYou can always build up on the backside to give it extra. Strength. It also works great onMoreYou can always build up on the backside to give it extra. Strength. It also works great on reattaching completely broken sections just clamp it in place and solder on all.

How do you restore diecast metal?

3:305:34Quick Tip: An Easy Way to Remove Oxidation from Diecast CarsYouTubeStart of suggested clipEnd of suggested clipI found toothpastes would be the best option as it's more abrasive than rubbing compound. But lessMoreI found toothpastes would be the best option as it's more abrasive than rubbing compound. But less abrasive than a wire brush.

Can diecast metal be welded?

Die cast parts made from the alloy AlSi9MgMn (Silafont-36) are particularly well suited for welding, both the standard MIG and TIG methods (see Gas-shielded welding processes) and laser beam welding.

How do you repair popping metal?

2:194:39Pot Metal Repaired By a True Beginner Using a Torch and Super ...YouTubeStart of suggested clipEnd of suggested clipCall up your local welder and ask them if pop metal can be repaired. They'll tell you to throw itMoreCall up your local welder and ask them if pop metal can be repaired. They'll tell you to throw it away as their local welding supplies says it can't be done.

Will JB Weld work on diecast?

The best glue for diecast metal, bar none, is JB Weld. If you're not familiar with it, it's a super-strong epoxy that sets up harder than steel. It's more brittle than steel, but it still makes an exceptionally durable bond.

Can you solder metal together?

SOLDERING has been used for centuries to join metals and is still one of the simplest and most widely used methods for securing metal joints and seams.

Can you glue metal to metal?

Epoxy Metal Glue Epoxy is usually the best glue for metal-to-metal joints. Epoxy for metal, like other forms of the adhesive, comes in two parts: a resin and a hardener. They need to be mixed together in equal proportions.

Can you solder Hot Wheels?

1:426:22How to Solder Hot Wheels ZAMAC Metal and Repair a Vintage Redline ...YouTubeStart of suggested clipEnd of suggested clipAnd then apply a tin soldering iron as the flux begins to boil off I'll come in with the solderingMoreAnd then apply a tin soldering iron as the flux begins to boil off I'll come in with the soldering wire add a little bit more. If all goes well the solder wets the surface. And sticks to the die cast.

Does diecast rust?

Aluminum, zinc, and magnesium are common metal materials used for die cast metal parts. While each metal type offers corrosion resistance, the levels of rust protection vary. Less common die cast metal includes brass, copper, or other specialty alloy materials.

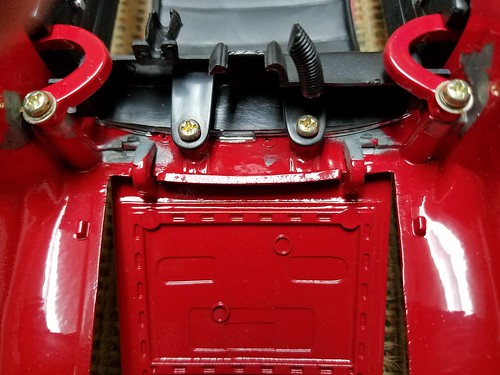

How do you restore a Corgi diecast car?

0:2510:56Powder Coating and Restoring a Corgi Toys No. 374 Jaguar E Type ...YouTubeStart of suggested clipEnd of suggested clipPlace the hatch in the back is a good example i struggle to get it off. And then decide that it can'MorePlace the hatch in the back is a good example i struggle to get it off. And then decide that it can't come off they must have crimped. It.

Can you solder zinc diecast?

While zinc die cast can be difficult to solder due to its low melting temperature of 786°F, Super Alloy 1 has a working temperature of 350°F, making it the ideal solution for soldering or brazing zinc die cast parts–with any torch: propane, MAPP gas, butane, acetylene, oxyacetylene, or even a heat gun.

Can you solder Hot Wheels?

1:426:22How to Solder Hot Wheels ZAMAC Metal and Repair a Vintage Redline ...YouTubeStart of suggested clipEnd of suggested clipAnd then apply a tin soldering iron as the flux begins to boil off I'll come in with the solderingMoreAnd then apply a tin soldering iron as the flux begins to boil off I'll come in with the soldering wire add a little bit more. If all goes well the solder wets the surface. And sticks to the die cast.

Can you solder zinc alloy?

Soldering with zinc-based alloys is achieved by applying zinc alloy in either a stick or powder form. The area being repaired needs to be preheated to approximately 600 F (315 C). The most commonly used solders for repair (Figure 55) include zinc-tin-lead, zinc-cadmium, and zinc-tin-copper alloys.

How to glue metal to diecast?

Apply a small amount of the metal glue to one side of the diecast and press that side against the unglued portion. Hold the metal together until the glue begins curing and is strong enough that it holds together on its own. Advertisement.

What are some things made of diecast metal?

Toy cars, collectibles and home decorations are just a few things made from diecast metal. The fabrication process uses lead metal, often mixed with another type of metal like aluminum or zinc. The liquid metal pours into a mold, creating the shape of the item. When the diecast metal becomes broken or otherwise damaged, ...

Can you use metal glue on diecast?

As metal glue is typically gray and resembles the natural color of the metal, so use the glue only on diecast pieces without any bright colors or high levels of decoration.

What is die casting?

Die casting is a process that can produce geometrically complex metal parts. lots of problems will occur when you don’t pay attention to it during production. A high level of technical expertise and attention to detail is required to prevent small errors from causing huge losses to the company in the mass production of new parts.

What is the characteristic of die casting gas?

Characteristic: the gas formed by the gas in the die-casting part has a regular shape and relatively smooth surface

What are the problems with castings?

1. The casting structure is unreasonable, the shrinkage is blocked and the casting fillet is too small. #N#2. The core pulling and ejection device skew in the work, uneven force.#N# 3. Mold temperature is low.#N# 4. Opening and core pulling time is too late.#N# 5. The use of alloy improper or harmful impurities is too high so that the plasticity of the alloy decreased. Zinc alloy, lead, tin, cadmium, iron, and high aluminum alloy: zinc, copper and iron, copper alloy high silicon high magnesium alloy: aluminum, silicon, high iron

How to keep crucibles from overheating?

1. The alloy should not overheat, avoid alloy long time insulation.#N#2. Increase the mold temperature, reduce the pouring temperature. #N#3. Strictly control the chemical composition of the alloy.#N#4. Keep the coating of the crucible intact and well.

How to refine aluminum alloy?

The aluminum alloy contains titanium, manganese, iron and other components, should not make segregation and keep clean, with dry refining agent refining, but in the aluminum alloy containing magnesium, should pay attention to compensation.#N#3. An aluminum alloy containing copper, iron content for a long time, should reduce the silicon content to below 10.5%, appropriately raise the pouring temperature, so that the silicon precipitation.

What are the metals that are used in alloys?

The use of alloy improper or harmful impurities is too high so that the plasticity of the alloy decreased. Zinc alloy, lead, tin, cadmium, iron, and high aluminum alloy: zinc, copper and iron, copper alloy high silicon high magnesium alloy: aluminum, silicon, high iron.

What are the features of a casting?

Features: the alloy matrix on the casting is broken or broken to form a slit with a fine wire. There are two kinds of penetrating and non-penetrating, which have a trend of development. Cracks can be divided into two kinds of cold cracks and hot cracks.

Can you clean die-cast metal?

Diecast metals can be cleaned which is important in maintaining their looks. However, you should take note that it is not as easy as wiping your diecast with any towel. It is important to know how to properly clean your diecast metal to avoid discoloration.

What Happens If You Clean Diecast Metals?

If you clean your diecast metals, the quality of your model will remain. This means that it keeps your models in good shape making it easy if you decide to sell them in the future. Another is that well-maintained models look more expensive to collectors and would prove your competence as a collector.