Can a wiring harness be repaired?

A common question asked of InterConnect Wiring is, “Can InterConnect repair or overhaul a wiring harnesses?” The short answer to this question is “Yes we can!” The long answer is that in many cases it is less expensive to produce a new wiring harness instead of repairing or overhauling an old one.

How do you fix a bad wire harness?

2:598:49How To Restore Any Wiring Harness - YouTubeYouTubeStart of suggested clipEnd of suggested clipAround the wire loom. Hold the wire loom as tight as you can but you don't want to do any damage toMoreAround the wire loom. Hold the wire loom as tight as you can but you don't want to do any damage to the wire. So you don't need to try and pull them apart just nice and tight.

How much does it cost to replace engine wiring harness?

The average cost to replace an engine harness is $1,100. This repair can range from a low of $700 to a high of $1,800. The part itself will cost you an average of $650, while the cost of labor to install an engine harness will average you $575.

How do you replace an engine wiring harness?

How to Replace a Broken or Damaged Wiring HarnessConfirm the Old and New Connectors Are the Same. ... Next Step to Replacing the Wiring Harness is to Strip the Ends of the Wires. ... Twist the Ends of the Wires. ... Crimp an Insulated Connector to the Wires. ... Melt the Insulated Connector to the Wiring. ... Apply Electrical Tape to the Wire.

How do you check engine wiring harness?

Turn on the switch powering the accessory and grab your multimeter. We're about to check for voltage. Touch the multimeter's negative lead to any good ground, and place the positive lead on the non-working vehicle accessory's positive terminal or wire leading to it to see if there is voltage flowing to the accessory.

What causes a wiring harness to go bad?

Wiring harnesses are machine-made. If the machine isn't well maintained or the technician applies incorrect settings, wiring harness problems can result. Some of the most common manufacturing mistakes occur due to improper wire layout, poor connection to the harness chassis, or the complexity of the design.

How hard is it to replace a wiring harness?

If the wiring harness in question is located in a tough-to-reach area, the technician may need to disassemble parts of the vehicle to gain access. In other words, installing a wiring harness could take as little as an hour, as long as 20 hours, or longer if complications arise.

How many wiring harnesses are in a car?

Some modern vehicles contain close to 40 different harnesses, comprised of roughly 700 connectors and over 3000 wires.

How much does a custom wiring harness cost?

PRICE: $3,500.00 Here at Rywire, We are capable of making custom harnesses for nearly any application and this product page is really a placeholder to show some of our custom work and encourage our community to call us with your project goals and let us price out a harness capable of doing what you need it to do!

How do you rewrap a wiring harness?

7:4311:10How To Wrap Engine Harness with Tesa Tape - YouTubeYouTubeStart of suggested clipEnd of suggested clipMaybe one or two times hang on how wide. The line is make sure if you're using this to wrap overMoreMaybe one or two times hang on how wide. The line is make sure if you're using this to wrap over itself because that's the way it'll get the best grip.

How do you know if your wiring harness is bad?

Look at the connectors and check for corrosion or other signs of damage. Examine the insulating wire wrapping for signs that it has cracked, dried out or warped. These are the kind of changes that can affect the performance of your wiring harness.

How do you know if your engine wiring harness is bad?

What Are Signs Of A Bad Wiring Harness? A dead battery or a rapid loss of charge can be a sign of a faulty wiring harness. Similarly, if your car suddenly starts or idles down unexpectedly, or if it stutters or lurches while driving, it is also a sign of a damaged wiring harness.

How do you find the bad wire in a wiring harness?

0:502:43How to locate a short in a wiring harness (visual inspection) - YouTubeYouTubeStart of suggested clipEnd of suggested clipRight here pushing and pulling. Away. Right here and that is exactly where this line is increasingMoreRight here pushing and pulling. Away. Right here and that is exactly where this line is increasing and decreasing so I'm going to do this again. While. I show you the scope.

How do you rewrap a wiring harness?

7:4311:10How To Wrap Engine Harness with Tesa Tape - YouTubeYouTubeStart of suggested clipEnd of suggested clipMaybe one or two times hang on how wide. The line is make sure if you're using this to wrap overMoreMaybe one or two times hang on how wide. The line is make sure if you're using this to wrap over itself because that's the way it'll get the best grip.

Chapter 2: What is Your Engine Wiring Harness?

An engine wiring harness is how each part of your vehicle gets electricity. It is crucial to help the vehicle run and for you to enjoy the music and tunes that you do on the regular. It’s just a bundle of cables. These cables connect from the engine to each part of the vehicle that needs electricity.

Chapter 3: What Does an Engine Wiring Harness Do?

Your vehicle needs more than your engine, and it requires a lot of electricity for certain things to function, like your radio or lights. Beyond that, your battery, starter, and even your alternator run on power, which is provided by the engine. Without an engine wiring harness, you couldn’t start your vehicle.

Chapter 4: How Does the Engine Wiring Harness Work?

There are many cables in the engine wiring harness that work to connect electricity to your vehicle parts. This vehicle part has many sensors, and they work to ensure that everything in your vehicle is in working order. Some of these major systems in your car are fuel and transmission.

Chapter 5: Signs to Look For When an Engine Wiring Harness is Broken

Your vehicle is crucial to you, and the engine wiring harness is also essential. It can be hard to diagnose when there is a problem. However, it could be as simple as a check engine light or another sensor. If you find that you have sensors going off, it may be your wiring harness.

Chapter 6: Repair and Replacement the Engine Wiring Harness

When it comes to repairing or replacing the engine wiring harness, there are a few options. First, it will depend on your vehicle. Sometimes, vehicle manufacturers require a full replacement. Other times, the repair is possible.

Chapter 7: Where to Find Help With Your Engine Wiring Harness

Mechanics work on all types of problems, but this problem is unique. People don’t see this issue every day, so it may not be something your local mechanic can help with. It’s important to call and talk to the mechanic. The first thing they will do is an inspection.

Chapter 8: The General Cost of Fixing Your Wiring Harness

The general cost of fixing your wiring harness can vary greatly. That is because it may just be one wire or ten wires that need fixing. It’s hard to get an estimate until you know precisely what you’re dealing with. However, if a mechanic has done enough of these projects, they may give you a general ballpark cost.

Why is specialty wiring so expensive?

If you are installing a specialty wiring – the cost of installation is expensive. It’s because the specialty wiring installation is very complicated.

How to change the wiring harness on a car?

Step 2 – Disconnect and remove the car battery from the vehicle using a socket wrench. Step 3 – Now, disconnect the primary connection of the engine body wire harness. Step 4 – Take a jack, jack up the vehicle, and disconnected all the wires from under the car. Step 5 – Install the new engine wiring harness.

What is the most important factor to consider when buying a wiring harness?

The most crucial factor of all for buying a wiring harness is the engine wiring harness repair cost.

How much does it cost to install a specialty wire?

On the other hand, the cost of a specialty wire starts at $90. Furthermore, the installation cost for a basic engine wiring harness is usually the specialty harness wiring installation. It is because specialty wiring is complex to install and takes more time and effort.

How much does it cost to replace engine wiring?

If you buy a basic engine harness wiring, it could cost $40 to buy it.

How much does it cost to buy a wiring harness?

The answer to this question is divided into three parts: Firstly, the cost of purchasing a wiring harness is expensive. You have to spend from $40 to $90 to buy a basic or specialty wire. It is essential to mention the price of the harness wiring could also vary from place to place.

How long does it take to replace a wiring harness?

A. It depends on how bad the damage is and the complexity of the harness wiring. Usually, it could take as little as one hour to up to 20 hours to replace an engine wiring harness.

What to do when a fuse blows?

Fuses are sized for whatever circuit is on the machine. Putting in a larger fuse to keep it from popping stresses the harness it was designed to protect , and you'll probably end up frying it.

What happens if a fuse blows despite having the correct amperage?

If a fuse blows despite having the correct amperage, your machine is telling you there’s a problem. It could be a short or an overloaded circuit, but whatever it is, you need to find and fix it. Don’t just cram in a larger fuse, as doing so risks damaging the wiring harness and potentially setting your machine on fire.

Why does my heat shrink have a gel fill?

Make sure the heat shrink you used has a gel fill on the inside because when it shrinks down, it's actually going to heat up that gel and completely encapsulate the connection on the inside. Bad wiring and connections are just one of various problems that can prevent your machine from starting or running properly.

What is the common mistake people make when adding on a light bar?

Wiring Add-Ons. Another common mistake people make when adding on a light bar or sound system is not paying attention to where they're routing their wires . A good rule of thumb is if you're going from one end of the machine or the other, follow the existing wiring harness.

Can you replace a wiring harness on a motorcycle?

Here are some ways you can remedy wiring harness problems, as well as things not to do, if you can’t replace an entire harness on a motorcycle, ATV or side-by-side.

Can you twist wires together?

Twisting it together and using electrical tape or other tape you may have lying around isn’t any better either, because as soon as there’s any stress, it could easily snap. Twisting wires together and using a plastic twist-on wire connector is also not the way to go, especially on ATVs and UTVs.

Can you run a Harley Davidson in a certain direction?

The manufacturer took a pathway that’s safe from heat and pivot points on the machine. So while it may look easier to run it in a certain direction, check what's around it. Whether it’s the exhaust or suspension pivot points, it’s going to affect that wire if it comes into close contact with the heat. Don't tag on to the existing wiring harness.

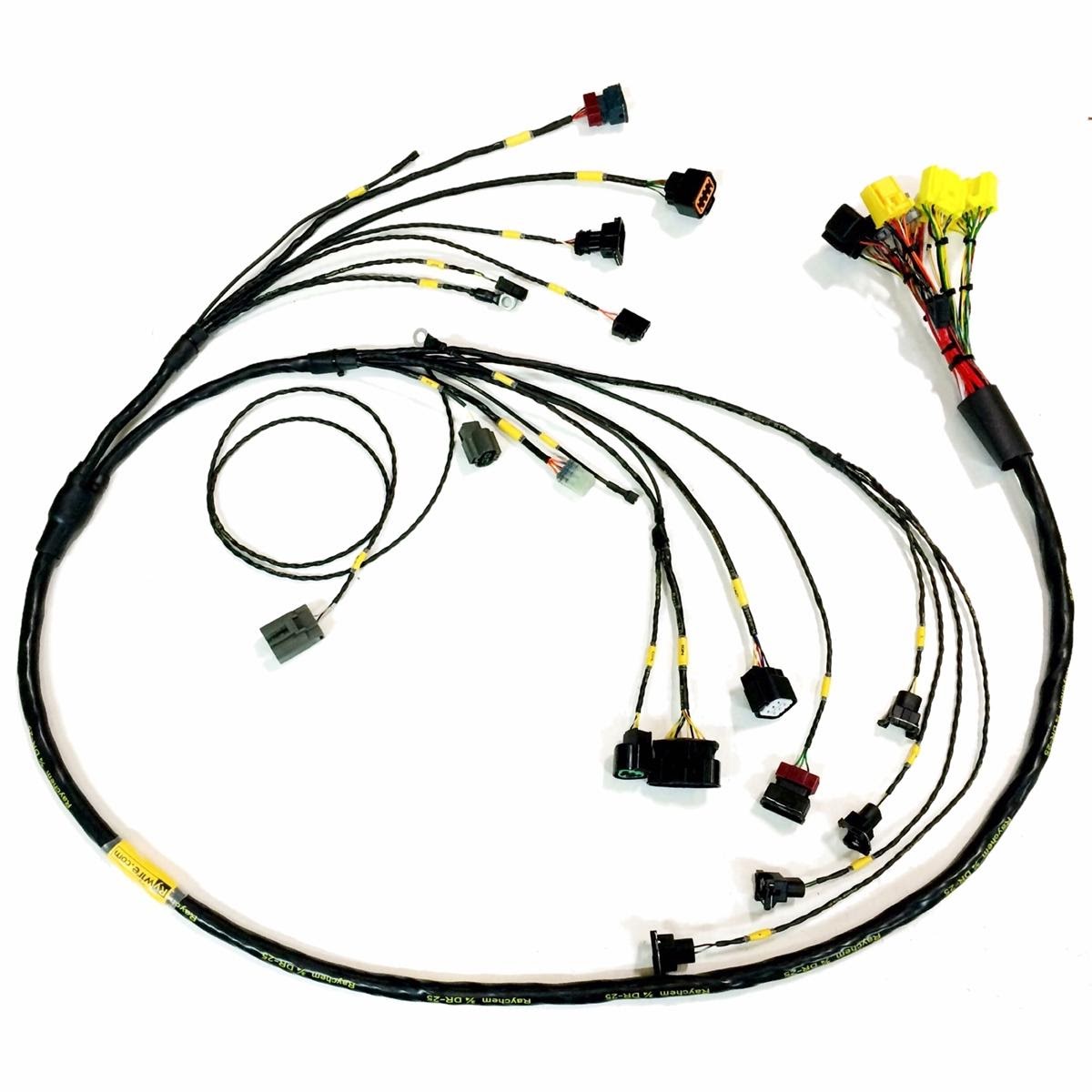

1. What is an Engine Wiring Harness?

An engine wiring harness is constricted wires, cables, terminals, and connectors controlling a vehicle’s electrical system. It relays electrical power and control information to components such as batteries, alternators, fuel injectors, fuses, audio systems, blower motors, fuel injectors, and computers.

2. Diagnosing a Broken Engine

The device served by the broken or damaged wire may stop working. So, you must diagnose it with proper tools.

3. The Cost of Engine Wiring Harness Repair

The cost of repairing your engine wiring harness will depend on the extent of the damage and the specific component of the harness that needs fixing. Ergo, the price could be under $100 or more than $1000. For example, a primary engine harness wiring could go for $40, while the cost of a specialty harness cable may begin at $90.

4. Buying an Engine Wiring Harness

You can either buy an aftermarket wiring harness or order a custom one from reputable manufacturers such as Cloom.

5. Replacing an Engine Wiring Harness

Replacing an engine wiring harness does not require extensive training. Just follow the process step-by-step.

Conclusion

With the high-performance demands of the original equipment manufacturing (OEM) marketplace, there is a relentless need to reach a consistent wire harness performance.

How to prevent wire from melting?

Melt the connector to the wiring with a lighter. Sway the lighter back and forth to prevent it from melting the electrical wire. 7. Apply Electrical Tape to the Wire. Once the connector has cooled, wrap the wire with electrical tape for an extra layer of protection.

How to check if a wire is a loom?

1. Cut Open the Wiring Loom. Pull the wiring out of the loom and check the condition of it. Check the wiring or burning, melting, or tearing. 2. Confirm the Old and New Connectors Are the Same. Confirm both the new and old electrical connector are the same.

What happens if an electrical connector melts?

You may need to do this repair if an electrical connector melts or burns for example. A melted or burned electrical connector can heat up and cause a fire if not replaced as soon as possible. 1.

Can a wiring harness burn out?

Sometimes electrical connectors or wiring harnesses can burn out or melt and need to be replaced. Luckily this repair is pretty simple. Our mechanic in the video below shows how to replace a wiring harness for the headlight wires, but the same procedure applies to a typical wiring harness.

Why does my hatchback door have a short?

Because these wiring harnesses run through tight spots, and are subject to tens of thousands of side or hatchback door openings and closings, there's ample opportunity for one wire in the bundle to break, or cause a short after its protective plastic cover has worn away.

What is a loose connection between the wire and that bolt?

a loose connection between the wire and that bolt. an issue with the ground wire, such as a visible trouble spot where the wiring harness is rubbing against something or where water and dirt might be present. use a jumper wire from the load to a known good ground to confirm there's a ground-side issue.

How to test wiring harness?

To test the wiring harness, first remove the wires connected to the accessory. Carefully trace the wires back to the first connection point you encounter. This may require the removal of the wires from the protective plastic tubing. Disconnect the wires at that first connection point encountered. 9.

Why don't we see wires in cars?

We don't see them, though, because that would just be unsightly and detract from a vehicle's stylish interior. Instead, all this wiring is bundled together inside flexible plastic conduit to create wiring harnesses that traverse the vehicle ...