Using buffers — such as pipe wraps, clamp liners, and wear pads — between dissimilar metals to eliminate galvanic cell creation and interrupt electrical paths. Plating, or galvanizing, is also an effective means of reducing galvanic corrosion risks or altering the electrode potential of components without completely changing their structure.

- Selecting materials with similar corrosion potentials.

- Breaking the electrical connection by insulating the two metals from each other.

- Applying coatings to both materials. ...

- Separating the two materials by inserting a suitably sized spacer.

What is galvanic corrosion and how can it be prevented?

To sum up, Galvanic Corrosion is a type of electrochemical corrosion. Where a material corrodes if it comes in contact with another material in the presence of an electrolyte. This phenomenon of metals is used to prevent corrosion of base metal by providing sacrificial coatings. We will keep adding more information on dissimilar material corrosion.

How can galvanic corrosion be reduced or eliminated?

How to prevent Galvanic Corrosion?

- Electro-chemically dissimilar metals with different anodic indexes.

- Dissimilar metals must be in electrical contact.

- Metals must be exposed to the electrolyte for the movement of metal ions from anodic to cathodic metal.

How does galvanizing protect steel from corrosion?

How does galvanizing protect steel from corrosion? Zinc metal used in the galvanizing process provides an impervious barrier between the steel substrate and corrosive elements in the atmosphere. It does not allow moisture and corrosive chlorides and sulfides to attack the steel.

How does coating with another metal prevent corrosion?

You can prevent corrosion by selecting the right:

- Metal Type

- Protective Coating

- Environmental Measures

- Sacrificial Coatings

- Corrosion Inhibitors

- Design Modification

Can Aluminium corrosion be repaired?

You can fix it by abrasion, removing the rot and filling/painting, just as with steel. Just as with steel though, once it takes hold you need to be utterly ruthless with treatment or accept that it will recur. Once you have repaired it, slather the whole thing in Waxoyl or similar wax, and keep the grot traps clean.

How can we prevent galvanic corrosion between steel and aluminum?

A good way to reduce corrosion is to use an isolating coating or paint on the aluminum and the steel to isolate them electrically. Insulating washers are also effective in isolating the two dissimilar materials and creating a relatively safe surface area.

What are the 3 essential conditions for galvanic corrosion to take place?

electrical continuity between the two metals.1 Different types of metals. Whenever two different types of metals are in contact, galvanic corrosion is possible. ... 2 Presence of an electrolyte. ... 3 Electrical continuity between the metals.

Does Teflon tape stop galvanic corrosion?

Modern engineers found a more effective solution to Lady Liberty's problem. They used PTFE (Teflon is the most common PTFE) polymer resin tape to isolate the different metals. This new type of barrier proved to be nearly impervious to corrosion.

How can we prevent galvanic corrosion between pipe and support?

The most common ways to prevent galvanic corrosion include: Electrically insulate the dissimilar metals using a brass nipple or other dielectric fitting (plastic in some applications) between the materials. A coat of grease and pipe tape can help to insulate steel and aluminum parts.

Will paint stop galvanic corrosion?

Paint provides barrier protection to materials that will also serve to decrease exposure to an electrolyte and slow down the accelerated corrosion process of a galvanic cell.

How do you remove galvanic corrosion from aluminum?

By combining distilled water with either pure lemon juice or white vinegar, and then gently agitating the corroded area with a mild scrubbing pad, most mild cases of aluminum corrosion can be removed.

What is galvanic corrosion how it can be prevented?

Prevention of Galvanic Corrosion Placement of Electrical Insulation between the two Metals to stop the flow of electrons between them and prevent galvanic coupling. Usage of a Galvanic isolator which can be two series-semiconductor diodes placed in parallel with two diodes that are conducting in the opposite direction.

Do you need water for galvanic corrosion?

Galvanic corrosion is when one metal causes another metal to corrode and break down. For this corrosion to start, there need to be three things: an anode (one metal), a cathode (a second metal), and an electrolyte (water is a common one).

Does galvanic corrosion need oxygen?

In the absence of dissolved oxygen or hydrogen ions to maintain the cathode process, galvanic corrosion does not occur. It is possible to combine different metals such as copper and steel in closed hot-water systems with little corrosion.

How do you separate galvanic corrosion?

Galvanic corrosion can be prevented by:Selecting materials with similar corrosion potentials.Breaking the electrical connection by insulating the two metals from each other.Applying coatings to both materials. ... Separating the two materials by inserting a suitably sized spacer.More items...

Does grounding prevent galvanic corrosion?

Please see National Electrical Code (NEC) Articles 250.52(A)(1), 250.53(D), 250.68(C), and 250.104(A). While we are not corrosion experts, grounding is a key component in reducing corrosion caused by galvanic action.

How do you insulate dissimilar metals?

How to Isolate Dissimilar MetalsGalvanize Metal. One way to protect dissimilar metals without adding large nonmetallic barriers is to galvanize metal. ... Use Liners. ... Elevate Piping. ... Use Buffers. ... Add Hangers.

Will stainless steel cause galvanic corrosion?

The combination of aluminum and stainless steel causes galvanic corrosion. In order to understand why you shouldn't use stainless steel and aluminum together, we first need to understand how galvanic corrosion works. Galvanic corrosion is the transfer of electrons from one material (anode) to another (cathode).

How long does it take for galvanic corrosion to occur?

The electrochemical potential difference between stainless steel and aluminium is in the range of 0.5 to 1.0 V, depending on the exact alloys involved, and can cause considerable corrosion within months under unfavorable conditions.

How can we prevent galvanic corrosion between steel and stainless steel?

Another method used to prevent galvanic corrosion is by electrically insulating the two metals from each other by using non-conductive materials such as plastics because if the two metals are not in electrical contact, no corrosion will occur.

What Is Galvanic Corrosion?

Galvanic corrosion is also known as dissimilar metal corrosion, and as the latter suggests, it occurs when steel comes into contact with another metal in a corrosive electrolyte.

What Causes Galvanic Corrosion?

Galvanic corrosion occurs when multiple dissimilar metal types come into contact in the presence of of conductive substance; one metal becomes anodic – meaning that it will corrode faster – while part of the remaining metal becomes cathodic – meaning that it will corrode slower, or not at all.

The Galvanic Series List

The galvanic series lists arrange common metals in order from the most anodic to most cathodic. The further apart the metals are on the list, the faster the corrosion rate will be. There are different lists for different conductive solutions, such as saltwater and freshwater, which will impact the speed of corrosion also.

Protecting Against Steel Corrosion With Steel Coating

Surface treatment is the most effective way to protect against corrosion. Here are some of the most common you will see steel fabricators use:

Need Help With A Steel Project?

If you have a project in need of steel, whether it’s supply, fabrication, drafting, or installation , talk to the experts at Steel Fabrication Services. Our dedicated team of professionals will ensure that your project goes according to plan right down to the smallest detail. Give us a call today!

How to prevent galvanic corrosion?

This mostly includes obstructing the electrical path in the metallic or electrolyte parts of the system, removing oxygen from the electrolyte, and the introduction of corrosion inhibitors.

Why does galvanic corrosion occur?

Galvanic corrosion occurs because electrons are allowed to flow from the anode to the cathode, producing a galvanic current in the system. Insulation material blocks the flow of electrons, thus preventing oxidation and reduction reactions from occurring.

How does the rate of galvanic corrosion affect the anode?

The larger the area of the cathode in relation to the anode (i.e., the higher the cathode to anode ratio), the greater the rate of reduction at the anode, thus the more severe the resulting galvanic corrosion. By contrast, the smaller the cathode to anode area, the less detrimental the ensuing deterioration.

What happens when two metals are in contact?

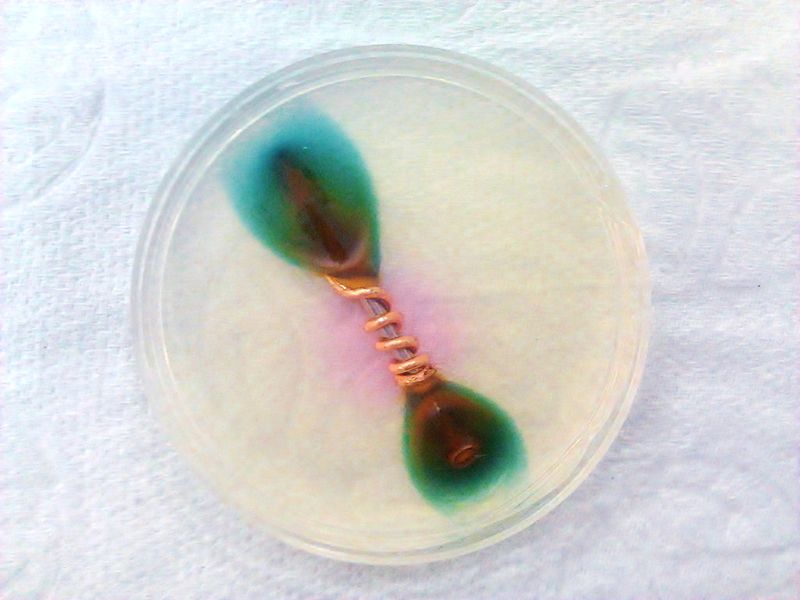

When two metals are in contact with each other while in the presence of an electrolyte, the potential difference that exists between them causes electrons to transfer from the anode (the more electronegative metal) to the cathode (the more electropositive metal). This transfer of electrons results in a series of oxidation and reduction reactions, which then causes in galvanic corrosion of the anode. (A further discussion is available in the article Why Do Two Dissimilar Metals Cause Corrosion?)

Why do electrons flow from anode to cathode?

As mentioned previously, the electrons flow from the anode to the cathode due to the potential difference, which acts as the driving force. The higher the potential difference, the greater the induced galvanic current, and the more severe the corrosion rate.

What is the primary driving force of galvanic corrosion?

The primary driving force in galvanic corrosion is a property known as potential difference. When a metal is immersed in an electrolyte, it adopts an electrode potential. The value of the electrode potential for various metals is represented in a table known as the galvanic series. The potential difference between the two metals is, therefore, ...

What is the purpose of an insulating gasket?

An insulating gasket placed between the flanges of connecting pipes to act as an electrical insulator. 2. Electrolyte Isolation. One of the main elements necessary for galvanic corrosion to occur is an electrolyte, which contains ions that facilitate the oxidation and reduction reactions in the galvanic cell.

What is Galvanic Corrosion?

Also known as bimetallic corrosion or dissimilar metal corrosion, galvanic corrosion is when corrosion damage occurs due to two dissimilar metals coupling in the presence of an electrolyte.

How many metals are needed for galvanic corrosion?

Galvanic corrosion requires two di ssimilar metals, in electrical contact, in the presence of an electrolyte to occur.

What are the best ways to minimize corrosion risks when pairing other metals with stainless steel?

Insulation, buffers, and plating all offer effective ways to minimize corrosion risks when pairing other metals with stainless steel products.

What is plating metal?

Plating, or galvanizing, is also an effective means of reducing galvanic corrosion risks or altering the electrode potential of components without completely changing their structure. For example, it is common to plate carbon steel fasteners with zinc to greatly improve corrosion resistance.

Can galvanic corrosion be eliminated?

Even with the ideal materials chosen, it may not be possible to completely eliminate galvanic corrosion risks. If so, insulating components and breaking the electrical path where possible are effective options to further boost corrosion resistance and ensure a long operational life.

Is galvanic corrosion a risk?

It is important to note that galvanic corrosion risks will also vary based upon the electrolyte connecting both metals. For example, the risks of galvanic corrosion in very pure water are minimal. Yet, deploy the same metals in a marine or chloride rich environment and you could see corrosion occur very rapidly.

Is stainless steel galvanic or anodic?

This means they are less likely to suffer damage from galvanic corrosion. However, if used with highly anodic fasteners, structural elements, valves, or other components, the large difference in nobility can lead to rapid degradation ...

What is Galvanic Corrosion?

Corrosion in metals deteriorates the metal parts due to chemical reactions between metal and the surrounding environment.

How can dissimilar metal corrosion be prevented?

Dissimilar metal corrosion can be prevented by ensuring electrolyte/water or any other conductive media is not in contact with dissimilar materials. Because in this way movement of metal ions from anodic to cathodic metal can be prevented.

What is anodic coating?

Anodic metallic coatings provide sacrificial galvanic corrosion protection to the base material. Metallic coating sacrifices itself to protect the base material. For example, Zinc coating on steel prevents galvanic corrosion of steel.

Why is the rate of corrosion higher in anodes?

Smaller the surface area of the anode compared to the cathode, Higher will be the concentration of flow of electrons from anode to cathode. As a result, the rate of corrosion will be high. Therefore dissimilar material corrosion can be prevented by avoiding small anodes in contact with larger cathodes.

Why must metals be exposed to electrolytes?

Metals must be exposed to the electrolyte for the movement of metal ions from anodic to cathodic metal. But in the real scenario, it is very difficult to avoid these conditions in product design. Therefore following points are considered during product design to reduce the impact of galvanic corrosion.

Why does corrosion occur on aluminum?

Aluminum works as an anode and steel as a cathode. Therefore corrosion occurs on aluminum because it has a higher anodic index value and works as an anode.

How to prevent dissimilar material corrosion?

Therefore dissimilar material corrosion can be prevented by avoiding small anodes in contact with larger cathodes.

What is corrosion survey?

Corrosion survey -- – The primary tool for a corrosion survey is a silver-silver chloride reference cell. This is a cell that is put in the water and connected to a volt meter. The resulting data indicates the protection level. A marine electrician will use this process to test hull potential to discover cathodic protection levels and test for stray currents. This is done at the slip where the boat is kept. While further lab tests can detect more extensive problems usually this type of visual examination suffices.

Where does localized corrosion occur?

Localized Corrosion -- Typically, this type of corrosion occurs within the vessel’s hull. Specifically, it affects metals that are:

What happens when two metals are touching each other?

When two different metals are touching each other or are electrically connected by a conductor, and are immersed in an electrolyte (an electrically conductive fluid, like salt water) an electro-chemical reaction can occur. One of the metals (the “least noble” metal, called the anode) will corrode faster than it normally would, and the other (the “most noble” metal, or the cathode) will dissolve more slowly.

Is electrolysis a component of galvanic corrosion?

Electrolysis (in this case related to DC currents), then, is a component of galvanic corrosion but the terms are not synonymous. Here's the major difference: