How to Repair a Bulkhead

- Step 1: Drill the Rotten Part. The first step to repair a damaged bulkhead is to drill the rotten part of the wood. Use...

- Step 2: Clean the Holes. Once you have removed all rotten parts completely from the bulkhead, the next step is to clean...

- Step 3: Fill the Hole with a Waterproof Sealant. Once you are done cleaning holes, the next step is to...

Full Answer

How do you fix a rotted bulkhead?

If you fill the holes and stabilize the bulkhead, you will not have to replace the bulkhead as quickly and can extend the life of the bulkhead by several years. Drill out any rotted wood around the holes with a drill. Sorry, the video player failed to load. (Error Code: 100013) Clean out the holes with acetone.

Why do bulkheads need to be replaced?

Over time, soil and water erode the bulkheads and cause small or large holes to form. If these holes are not addressed right away, they become larger, eventually requiring bulkhead replacement.

How can I extend the life of my bulkhead?

If you fill the holes and stabilize the bulkhead, you will not have to replace the bulkhead as quickly and can extend the life of the bulkhead by several years. Drill out any rotted wood around the holes with a drill.

What is a bulkhead made of?

These are typically made from wood planks placed on top of each other to create a soil barrier and are often used in marinas, around lakes, ponds and homes built on lake front or ocean front property. Over time, soil and water erode the bulkheads and cause small or large holes to form.

How do you repair a hole in a metal bulkhead?

0:336:52Repairing a bulkhead hole - YouTubeYouTubeStart of suggested clipEnd of suggested clipI'm going to cut a new bulkhead at the top of this tank. So I'll use that circle that I remove as myMoreI'm going to cut a new bulkhead at the top of this tank. So I'll use that circle that I remove as my patch material to put over this old hole. So I have going in and selected a drill.

How do you repair a hole in a bulkhead?

Drill out any rotted wood around the holes with a drill. ... Clean out the holes with acetone. ... Fill the holes with waterproof epoxy sealant.Place 2-inch pressure treated planks horizontally over the holes. ... Screw the planks in place with 6-inch screws every 24 inches along the plank.More items...

How do you fix a leaking bulkhead?

How to Fix a Leaking Cellar BulkheadPinpoint the source of the leak. ... Seal cracks in the concrete stairs and frame where the bulkhead doors are mounted using a concrete sealant. ... Apply waterproof sealant that will bond with both concrete and metal around the edges of the bulkhead door, both inside and outside.More items...

How do you replace a metal bulkhead?

0:0611:43How to Replace Basement Bulkhead Doors | Ask This Old HouseYouTubeStart of suggested clipEnd of suggested clipTo get started we need to remove the bulkhead I'm using a grinder with a 5 inch cutoff wheel to cutMoreTo get started we need to remove the bulkhead I'm using a grinder with a 5 inch cutoff wheel to cut the old hinges. And free the doors.

How can we prevent erosion behind a bulkhead?

To correct this, it is necessary to excavate behind the bulkhead and repair or replace the broken tieback. If excavation is not possible, bracing along the front of the wall with “batter” piles (piles driven into the ground at an angle and attached to the vertical wall piles) may be suitable in some cases (Fig.

How do you fix a washout on a seawall?

Innovative ground stabilizing methods using polyurethane foam injections are typically used to raise and level damaged seawalls caused by erosion. Poly foam replaces the soils behind the seawall, creating a long-term bond that strengthens the ground, eliminating deterioration and erosion.

How do you seal a bulkhead from water?

2:463:55How to Seal a Leaking Cellar Bulkhead - YouTubeYouTubeStart of suggested clipEnd of suggested clipWithout getting tired all over yourself to put the tower. Along. We heat it to at least 70 degreesMoreWithout getting tired all over yourself to put the tower. Along. We heat it to at least 70 degrees and we spread it you on the wood using a putty knife or or a flat step.

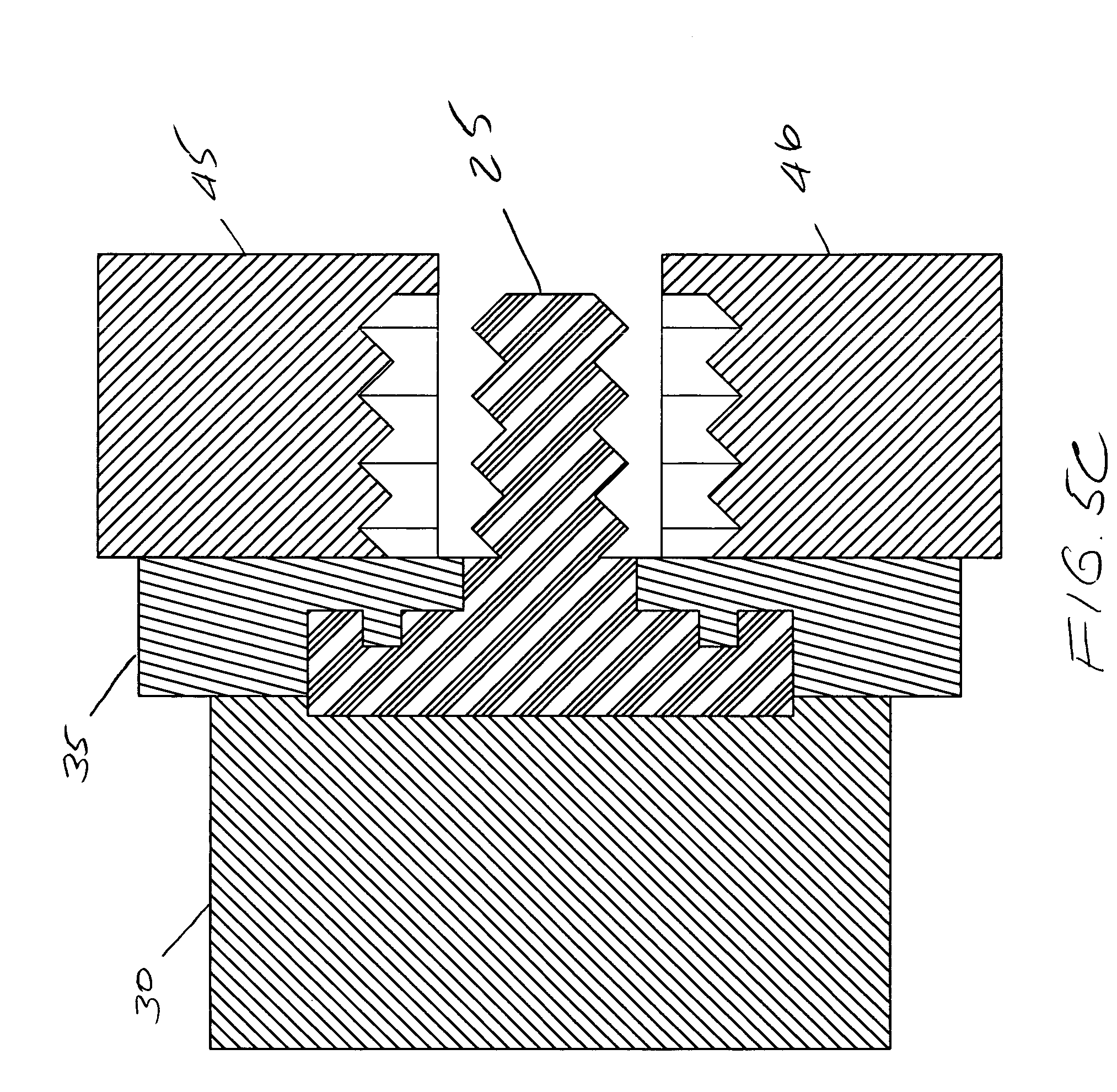

How do you seal a bulkhead fitting?

Fitting, the bulkhead fittings seal by drilling a single hole into the sidewall of the tank. The installer places a ring gasket onto the bulkhead fitting, and it goes from the inside of the tank to the outside through the hole. A compression nut then threads onto the bulkhead fitting, is tightened up and is sealed.

How do you waterproof a bulkhead door?

To seal your basement bulkhead door that is both quick and cost-effective, you could fill the gaps in your bulkhead door with a concrete sealant. You could also install a rubber seal around the perimeter to properly seal your door.

What does it cost to replace a bulkhead?

Overall, you can expect to pay anywhere from $500 to $1,600 to replace a basement bulkhead door, excluding installation and removal costs....Highlights.Minimum CostNational AverageMaximum Cost$200$1,100$6,000May 26, 2022

Can you replace a bulkhead?

To replace your existing bulkhead doors, start by cutting through the hinges on the old bulkhead doors using a right-angle grinder fitted with a cutoff wheel. Remove both doors, then use the grinder to grind off the screw heads from the brackets that secure the bulkhead to the foundation.

How much does it cost to put in a new bulkhead?

Bulkhead or seawall cost per foot. The cost to build an ocean bulkhead or lake seawall is $150 to $600 per linear foot. A steel, vinyl, or concrete seawall costs $200 to $600 per linear foot. A wood seawall costs $150 to $500 per linear foot.

Why are bulkheads used?

Bulkheads are designed to hold the shoreline in place to prevent erosion. These are typically made from wood planks placed on top of each other to create a soil barrier and are often used in marinas, around lakes, ponds and homes built on lake front or ocean front property. Over time, soil and water erode the bulkheads and cause small ...

How to install 2x4 planks?

Place 2-by-4 boards horizontally on top of the 2-inch planks. Screw the 2- by-4 boards in place using the same screws and washers that you used to secure the smaller planks in place.

Step 1: Planning

I determined the dimensions and marked each property line for the turnbacks. I figured out the material list for each property. I picked up the material I could and had the rest delivered. Then I got to work.

Step 2: Installing the Posts

On average the distance of the property was 50 feet. I spaced the posts out between 4 to 5 feet between each one. I tried different methods from using a post hole digger, an auger and eventually a jetting method using a high pressure water stream to move the dirt in order for the posts to sink.

Step 3: Installing the Boards

The bottom board had to be jetted into the mud and secured with stainless steel screws. Each board was cut in order for the ends to land on a post. After the first board was secured the rest went in much easier. All boards secured with stainless steel screws.

Step 4: Installing the Top Plate

After installing all the boards on the posts I cut the posts. I used a circular saw and a reciprocating saw. I marked the lines with a speed square. When everything was flush I installed the top plate. I used 2 x 6's for the top plates.

Step 5: Installing the Deadmen

I used 4 x 4's for the deadmen. "Deadmen" help to anchor the wall in place when building a retaining wall. I used a post hole digger to embed them fully into the ground. Then I drilled a hole through them and installed the appropriate hardware. I used galvanized steel wire rope with turnbuckles, eyebolts and wire rope clips.

Step 6: Installing the Drainage

I connected all the downspouts to drainage lines that went into the ground and out the wall. I used a hole saw in order to cut the 4" hole in the wall. I made sure the appropriate slope was on each line in order for the water to be able to drain out naturally. I also added a soil barrier between the wall and where the fill dirt was to go.

Step 7: Fill Dirt and Topsoil

I had fill dirt brought in and then used a wheel barrow to move it into the backyards. Nothing fancy here just a lot of back and forth. I used a water hose and tamper to make sure the dirt was being compacted. It also rained for several days which helped to compact everything.