How to Repair a Leaking Metal Gas Tank Without Welding

- Removal procedures will vary between vehicles, I will have a video covering the specific removal for this car which will be released in the future.

- Tape up any lines where dirt can risk falling inside of the tank. ...

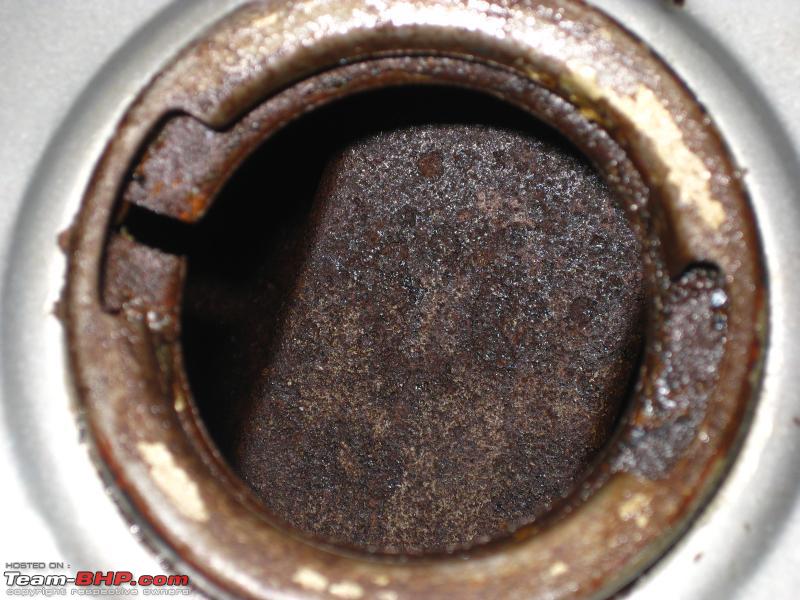

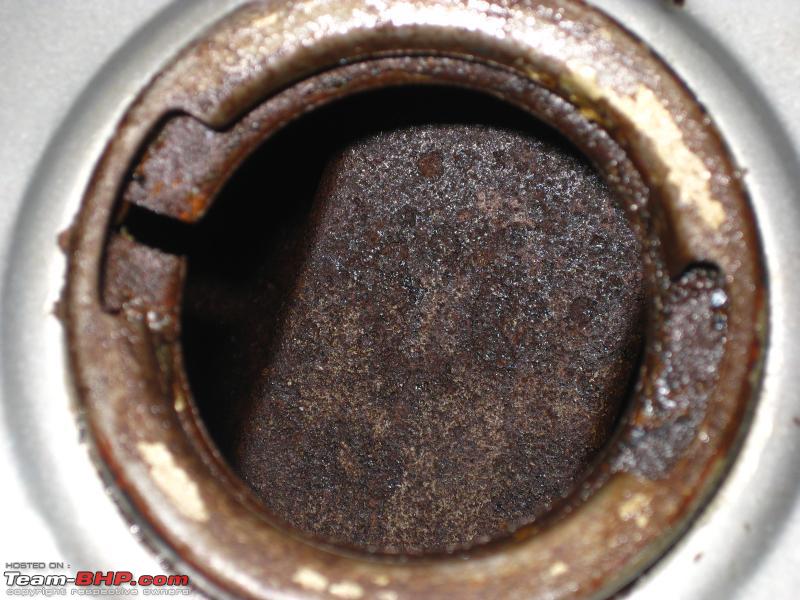

- The most efficient was to remove rust in these hard to reach areas is using a media blaster. ...

- Using an etch primer, this will help improve paint bonding and also help reduce the risk of further rusting.

- Here I have an aircraft grade fuel tank sealant. There are various quantities available, I purchased this online from an aircraft parts supplier.

- Blow away any sanding dust, then give the tank a final cleaning using isopropyl alcohol to remove contaminants.

- After it did dry, I left it for a couple of days but this will vary depending on the thickness of paint and your climate.

- I did install the fuel pump to prevent any dirt from dropping inside the tank when it goes back into the car.

How to clean a rusty fuel tank?

Working With Gas Tank Treatments: Safety Precautions

- Work in a well-ventilated open space to avoid breathing in intense vapors.

- Products should not be mixed except in accordance with the manufacturer’s instructions to avoid the possibility of chemical reaction.

- Before removing the gas, tank or utilizing any combustible product, make sure that all heat and power sources are turned off.

How do you clean rust from a fuel tank?

What Cleans Rust Out of the Gas Tank?

- Evapo-Rust The Original Super Safe Rust Remover. This product is an environmentally safe product that can help you remove rust in your gas tank that works within a couple of ...

- WD-40 Specialist Rust Remover Soak. ...

- OXALIC ACID 99.6% 2 Lb. ...

- POR-15 40704 Rust Remover. ...

- JENOLITE Original Rust Remover. ...

- POR-15 49216 Fuel Tank Sealer. ...

How to properly fill outboard fuel tank?

Possible Solution:

- Screw Driver.

- Brush.

- Warm Water.

- Carb Cleaner. Replacing the broken or collapsed bulb is the solution here. Then re-prime the engine and check if the boat runs without a problem.

How to remove an old fuel tank?

How to Safely Drain Your Gas Tank

- There are a number of reasons that you may find it necessary to drain all of the fuel out of your gas tank.

- When most people think about siphoning gas out of a car or truck's gas tank, an ugly picture comes to mind.

- Before you start pumping, be sure you are set up. ...

How do you fix a hole in a metal gas tank?

Step 1 - Jack up the Vehicle. ... Step 2 - Find the Leak or Hole in the Gas Tank. ... Step 3 - Sand the Leaky Area of the Tank. ... Step 4 - Clean the Surface. ... Step 5 - Mix the Epoxy. ... Step 6 - Shape and Apply the Epoxy. ... Step 7 - Insert the Epoxy in the Hole. ... Step 8 - Fill the Tank with Gas.

How do I fix a leaking metal tank?

0:162:17Metal Tank Repair - Fix Bad Water Leak in Water Holding Tank from WellYouTubeStart of suggested clipEnd of suggested clipWe chose quick steel for our epoxy. Because it is waterproof molded it into a ball. And filled theMoreWe chose quick steel for our epoxy. Because it is waterproof molded it into a ball. And filled the whole stick it in one to cover the plug we selected jb weld. Applied it over the.

Can a fuel tank be repaired?

Unless the gas tank has already been removed from the vehicle, you can't repair it without getting underneath it. Most leaks are visible from the underside and can easily be patched up.

Will JB Weld fix a metal gas tank?

Supplies. JB Weld also makes a gas tank repair kit, which consists of a tube of epoxy putty, fiberglass cloth, sandpaper, and an applicator. This repair is the same as the SteelStik, but adds some additional strength with the fiberglass. This is best used in larger repairs or on a tank with multiple pinhole leaks.

Can you weld a metal gas tank?

Yes, you can use a JB Weld on a gas tank. JB Weld is both water and gasoline resistant and has a tensile strength of 5020 PSI and can withstand up to 550 degrees Fahrenheit. What is this? Apply the putty firmly over the hole, working the edges of the product flat against the tank to create a seal.

What can I use to patch a gas tank?

0:217:19How to fix a leaking gas tank - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo what I went out and got is this kit right here gas tank repair kit and it's a two-part putty youMoreSo what I went out and got is this kit right here gas tank repair kit and it's a two-part putty you just mix it together.

Can you weld a fuel tank?

The process of welding gas or diesel tanks can be extremely dangerous. There is the possibility of igniting fuel vapors, and if the welder is using the welding process of MIG or TIG inside a fuel storage tank, they are in danger of suffocating from fumes if argon gas is used.

What kind of glue is gas resistant?

Seal-all is the adhesive mechanics and hobbyists trust for all their automotive and garage repairs. It Adheres with superior strength to most substrates and resists gasoline, oil, paint thinner, and solvents. Seal-all does not require mixing or heating and will not become brittle.

How long will J-B Weld hold on a gas tank?

Epoxy PuttyJ-B Weld TankWeldJ-B Weld The Original Cold WeldSurface ApplicationIron & Stainless Steel, Copper & Brass, and Aluminum & BronzeGreat For: Metal, Wood, Plastic, Tile, PVC, Ceramic, Fiberglass, Concrete & MoreCure ColorDark GreyDark GreySet Time5 Minutes4-6 HoursCure Time1 Hour15-24 Hours3 more rows

What epoxy is gas resistant?

Loctite Epoxy Weld does not shrink and is resistant to most shop fluids such as water, diesel fuel, gasoline, antifreeze, hydraulic fluid, motor oil and transmission fluids.

Does Flex Seal work on gas tanks?

Can I Use Flex Seal Tape On My Gas Tank? No. Flex Seal Tape™ is also not resistant against a corrosive flammable such as gas or oil. Neither of the Flex Seal™ products is good on gas tanks.

How to remove rust from a tank?

The most efficient was to remove rust in these hard to reach areas is using a media blaster. Any opening in the tank can be plugged or taped off so no dirt, rust, or blasting media falls inside.

How to clean a sanded tank?

Blow away any sanding dust, then give the tank a final cleaning using isopropyl alcohol to remove contaminants.

How long does it take for a tank sealant to cure?

The one I purchased does have a longer work time and will take slightly longer to cure. This one takes 36hrs to fully cure. Make sure you’re far enough past the leaking areas to provide a strong bond and this will provide an excellent seal.

What to use to clean oil tank?

Wax or oil may be still on the surface, use a wax and grease remover to clean up the tank. I used paper towel as it’s easily disposable.

Can you use a sanding disc on a tank?

If you don’t have access to sanding blasting equipment, you can use a surface sander too with 80 grit sanding discs. Abrasive pads can also be used and will strip the surface down very efficiently too. While I can strip the whole tank to bare steel, it really doesn't need. The areas which have rust will be addressed and repaired accordingly.

Can you fill a mig welding tank with argon?

In addition to this, the tank can also be washed out with soap and water. Or it can also be filled with argon which is used for mig welding when cleaning up those rusty areas. Getting the tank ready to clean up the rust and repair the leaking area.

Can you spray paint a fuel pump?

Work in a well-ventilated area away from anything you don’t want overspray on, use the correct safety equipment such as a respirator and apply the paint. Some paints can also be purchased in a spray can and you can certainly go with that route too. Any area which is required will need to be taped off such as the tip of the filler neck and the gasket sealing area for the fuel pump.

How long to keep rust sealer in a tank?

It will neutralize rust prior to adding the sealer. Keep the product in the tank for 30 minutes to an hour's time, agitating the tank every five minutes.

How to clean a KBS tank?

The first step was to wash the tank with the KBS Clean cleaner/degreaser solution. Mix the cleaner with water at a 1:1 ratio, then pour it into the tank.

How much does a KBS gold standard tank sealer cost?

It's a three-step system that cleans, preps, and seals the tank. With a retail price of $69.95, the kit is affordable and easy to use, and it treated our 20-gallon tank with plenty of sealer to spare.

How long does it take to seal a quart tank?

The Tank Sealer is applied similarly by pouring the entire quart in the tank, taping off the filler neck and sending unit openings, and tipping and rotating the tank at regular intervals for a period of 30 minutes. This will ensure the entire inside of the tank is coated with the sealer. Pour out any remaining sealer after the allotted time. We had slightly less than half a quart left, so the quart-size container could treat much larger tanks than ours.

How long does it take for a KBS tank to dry?

KBS recommends drying the tank with compressed air or even a hair dryer. We found a length of HVAC ducting and routed it to a room heater. After about an hour the tank was completely dry.

Can a strainer clog a fuel filter?

It's important to consider all the components of your fuel system when diagnosing a problem. Pieces of the strainer can clog a fuel filter to the point of choking it off. Bits that get past the filter can clog carburetor jets and passages or fuel injectors, causing all sorts of drivability problems. See all 19 photos.

What are the problems with a metal gas tank?

Gas tank problems: There are three possible problems with plastic or metal gas tanks. Pin hole leaks. A crack in the tank. A hole in the tank. We will cover how to repair each problem for both plastic and metal gas tanks. Issues of Concern: Whenever there is a crack in a plastic or metal gas can, you need to drill a hole at each end ...

Why do you need to drill holes in gas cans?

Whenever there is a crack in a plastic or metal gas can, you need to drill a hole at each end of the crack to prevent that crack from widening. If you do not drill a hole at each end, the crack will lengthen and leakage will result. When there is a problem with a metal tank, there is often a loss of substrate due to corrosion.

Can gas eat adhesive?

There are two obstacles that are not usually considered in the repair of a gas tank. These issues are: Gas will eventually eat through most adhesives. Gas, oil, nor any hydrocarbon will not have any effect of our SI Structural Adhesives … ever.

Do plastic gas tanks expand?

Gas tanks, especially plastic gas tanks, expand and contract. Cured adhesives do not expand or contract. When gas tanks expand, cured adhesives crack. Gas then leaks. A repair on any gas tank, but especially plastic gas tanks needs to be able to handle the expansion and/or contraction that comes from changes in temperature.

Can steel fuel tanks rust?

Sooner or later, all steel fuel tanks are likely to have the same problem. They will begin to rust, flake and develop pinhole leaks. But there's an inexpensive way to repair old tanks, says Gackle, N. Dak. farmer Roger Gutschmidt.

Can Gutschmidt run into fuel line?

You can't let the product run into a fuel line and if you have a shut off valve in the bottom of your tank, you have to take that out and screw a pipe plug into its place.". Gutschmidt let the product dry for 24 hrs. before reinstalling the tank into the tractor.