How to Fix a Rusted Metal Railing

- 1.. Cover the area around the railing with drop cloths and tape off anything else you want to protect using painters...

- 2.. Sand off as much of the rust as possible using abrasive tools. If your railing is mostly smooth and unornamented,...

- 3.. Apply naval jelly to any remaining rust with a paintbrush. Naval jelly contains phosphoric...

Full Answer

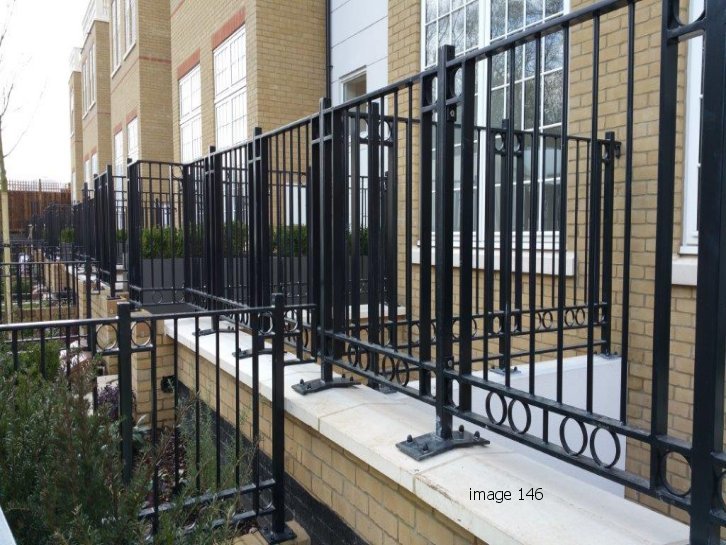

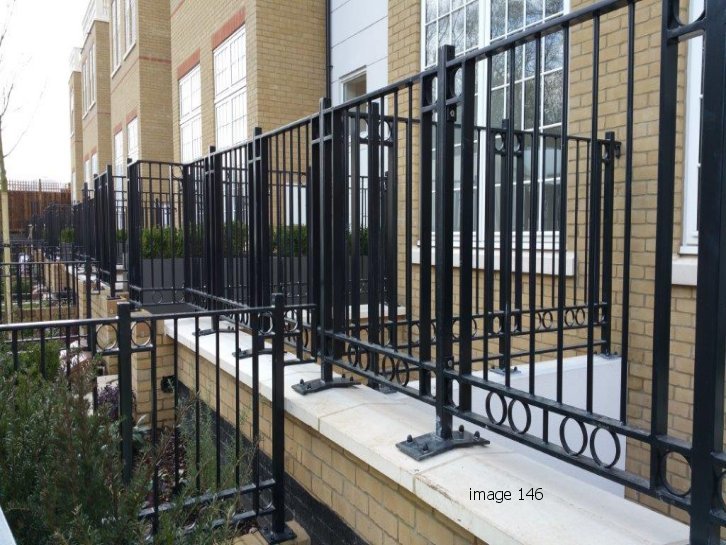

What is the cost to install a metal railing?

The cost to have metal or cast iron deck railing installed professionally starts at $40.00 per linear foot for affordable steel and can reach $125 per linear foot for ornately fashioned wrought iron. That’s $2,000 to $6,000 for a deck with 50 linear feet cast iron deck railing.

How to fix a rusted metal railing?

- Sand the broken surfaces to remove approximately 1/4 inch of paint from both ends of the break.

- Remove grease and dirt from the surface of the wrought iron with a clean rag dipped in mineral spirits.

- Mix the epoxy weld or epoxy resin per the instructions on the packaging.

How to install a metal railing?

Steps for Installing a Metal Railing

- Locate a local welding company to make the railings for the steps. ...

- Measure roughly 4” from the wall and 4” from the edge of the steps to place the railing. ...

- Use the masonry drill to clean out the hole made by the coring drill.

- Dry fit the railings to ensure a correct fit.

- Pour a small amount of the anchoring cement into the mixing cup and add water. ...

Can I remove the railing?

When the porch railing no longer provides the necessary level of protection for your home, you will need to remove the old structure and replace it. Take measurements of the existing porch rail so you can make accurate cuts for the replacement. Recognize that wood expands over time, so you must make allowances for settling.

How do you fix a broken metal railing?

1:285:21How to Repair a Rusted Wrought Iron Railing | This Old House - YouTubeYouTubeStart of suggested clipEnd of suggested clipTo do that I'm going to use a hammer drill with a masonry bit I'm going to put it in the hole. And IMoreTo do that I'm going to use a hammer drill with a masonry bit I'm going to put it in the hole. And I set my depth stop because I don't want to go too deep.

How do you fix wrought iron without welding?

Epoxy is one of the easiest ways to repair broken wrought iron without welding. However, if you are fixing a more ornamented piece that is hard to clamp, it might be worth your while to consider a quick weld as it will set in place quicker. That being said, most breaks in wrought iron can be repaired with epoxy.

How do you touch up iron railings?

How to touch up your Wrought Iron RailingFirst: Clean the railing thoroughly.Second: sand the rust lightly. This step depends on the gravity of the rust. ... Third: Prime the spots with a Rustoleum primer. ... Fourth: Wait until the primer dries and apply the final paint.Side Note: Ordering the paint can be daunting.

How do you fix a chipped railing?

0:211:56How to Repair a Handrail - YouTubeYouTubeStart of suggested clipEnd of suggested clipTogether you might have some excess adhesive come up so just scrape it out of the way. Then we canMoreTogether you might have some excess adhesive come up so just scrape it out of the way. Then we can get busy cleaning up the rest of the rail. I'm going to scrape off the loose flakes.

How do you bond metal to metal without welding?

Bonding compound: Loctite Weld Another option for gluing metal is Loctite Epoxy Weld Bonding Compound. A convenient alternative to welding, it's the strongest solution for bonding most metals, including iron, steel, aluminum, brass, copper, and pewter.

How do you fill holes in metal without welding?

Epoxy or Tape Epoxy and tape are two common no-weld hole repair options. These do-it-yourself approaches are effective when repairing a small hole rather than a significant tear. Specialty epoxy and tape products are designed to patch steel and metal.

How do I fix peeling wrought iron?

0:303:20HOW TO FIX PEELING PAINT ON METAL - OUTDOOR LANTERNSYouTubeStart of suggested clipEnd of suggested clipSo have a scraper and some sandpaper. And some sponge. And some brushes brushes for cleaning brushesMoreSo have a scraper and some sandpaper. And some sponge. And some brushes brushes for cleaning brushes for painting painters tape gloves alcohol. For later cleaning. And also some paper towels.

How do you restore a rusted railing?

1:428:24How to Repaint a Rusty, Metal Hand Rail | Ask This Old House - YouTubeYouTubeStart of suggested clipEnd of suggested clipGo. Okay for the flat surface we're gonna use a metal blade with a scraper. And then for all theMoreGo. Okay for the flat surface we're gonna use a metal blade with a scraper. And then for all the curved surface we're gonna use a wire brush. So we trying to scrape off the paint or the rust.

How do you fill holes in wrought iron?

Putty can be used to fill holes caused by rust in your wrought-iron fence. Though not common, it's possible for a wrought-iron fence to suffer from enough rust damage that the rust eats its way through the iron.

How do you repair a front porch railing?

0:023:24Tommy and Nathan Repair a Porch Railing | This Old House - YouTubeYouTubeStart of suggested clipEnd of suggested clipWell the homeowner wants to tighten a few things up around the house. So we're going to start withMoreWell the homeowner wants to tighten a few things up around the house. So we're going to start with this lower railing right here as you can see extensive damage to the lower part.

How do you restore a wrought iron railing?

1:162:16How to Paint a Rusted Wrought Iron Railing - YouTubeYouTubeStart of suggested clipEnd of suggested clipInto a tray. Starting with the top railing use light even strokes. If you're using a roller workMoreInto a tray. Starting with the top railing use light even strokes. If you're using a roller work back and forth rolling away from previously coated areas use a brush on curves crevices.

Can JB Weld be used on wrought iron?

Use of Epoxy Putty to Repair Cracked Cast Iron What is this? First, buy epoxy putties such as Quick Steel or JB Weld at your local hardware store. These two types of epoxies will serve as glue and will adhere to cast iron and fill the crack with a safe seal.

What can I do instead of welding?

Alternatives To WeldingBrazing. Brazing is similar to welding but instead of melting two pieces of metal to join them together, you melt a filler metal that you place between the two metals that you want to join together. ... Soldering. ... Riveting. ... Metal stitching. ... Looking for sheet metal machinery?

How do you glue wrought iron?

First, buy epoxy putties such as Quick Steel or JB Weld at your local hardware store. These two types of epoxies will serve as glue and will adhere to cast iron and fill the crack with a safe seal. Using 80-grit sandpaper, sand the cast iron to remove any paint and rust that might be covering the crack.

Can rusted wrought iron be repaired?

It is possible to do basic repairs yourself. Rust spots can be scrubbed away using a wire brush and sandpaper (wear a face mask, as the iron dust can cause problems if it gets into your lungs). If the hole is large, fill it in with putty. You can then repaint that part of the fence.

Can wrought iron be soldered?

You can use solder to repair simple problems with wrought iron, like cracks or dents, or to seal broken pipes. Wrought iron items are made by heating iron to a temperature of 1371°C or greater, and then using tools to shape it and weld it together.

What to use to sand a railing?

If your railing is mostly smooth and unornamented, wire brushes, sanding sponges, steel wool or a small power sander should be suitable. If your railing is more ornate and has areas that are hard to reach, you might also need sanding tape and sanding cord to access difficult spots.

Can you use a rust converter on metal?

If you find any, apply a rust converter to them. This causes a chemical reaction that prevents the rust from spreading or doing further damage. Rust converters often leave uneven surfaces on the metal, so after the length of time specified by the manufacturer, sand the area again to smooth it.

Can rust damage a railing?

Rust on your railing isn't just an aesthetic problem -- left unchecked, rust also damages the railing itself, making it less sturdy. A small area of rust on an iron or steel railing can quickly become a large area of rust, so address the problem as soon as you spot it. The more ornate your railing, the trickier it can be to remove ...

Can you leave a sanded railing without primer?

Avoid leaving bare sanded areas overnight without primer. If only one or two spots on the railing need a rust repair filler, prime the rest of the railing before repairing those spots. This prevents new rust from developing in other places while you wait for the filler to cure. Writer Bio.

How do I remove old paint from metal railings?

1. Brush off old flaking paint. Use a steel brush to get rid of all loose and old flaking layers of paint. This is important – the new paint won’t bond with the existing paint and protect the metal unless the railings are cleaned of loose rust and unsound paint.

What are the problems with metal railings?

Spotting problems with metal railings and gates 1 Damaged paintwork 2 Blistering, discoloured paint or pitted surfaces 3 Corrosion and failing joints 4 Damaged or missing sections 5 Moisture or dirt 6 Moss or plant growth 7 Rust staining to renders, masonry and other surfaces in contact with ironwork, including pillars and plinths 8 Cracking to masonry where ironwork is attached 9 Squeaking, binding or sagging gates

Why are railings vulnerable to corrosion?

Railings and other metalwork is vulnerable to damage due to fractures, rust and other forms of corrosion. All items should be regularly and carefully maintained and, where necessary, cleaned, painted and lubricated. RECOMMENDED VIDEOS FOR YOU...

Why is it important to finish ironwork?

Regular finishing of ironwork such as railings and gates is essential to avoid rusting and decay caused by exposure to air and water. Good preparation of the surface is essential and all loose paint and rust must be removed first. You will need. Steel brush. Scraper.

How do I clean a wooden railing?

Wearing gloves and using a clean cloth, wash the railings thoroughly with a solution of sugar soap dissolved in hot water. This will get rid of all the dirt and grime and any greasy deposits, too. Once the railings are completely clean, use a new cloth and lots of water to rinse away the dirty suds.

What metals are used in railings?

The ferrous metals – those containing iron – that are used in railings or gates are not always easy to tell apart, especially as they are often concealed under thick coats of paint and different metals are used in combination. For example, the decorative heads on wrought-iron railings are sometimes cast iron.

What is rust staining?

Moisture or dirt. Moss or plant growth. Rust staining to renders, masonry and other surfaces in contact with ironwork, including pillars and plinths. Cracking to masonry where ironwork is attached. Squeaking, binding or sagging gates.