How do you fix a pallet jack that won’t pump up?

- Prop Up the Pallet Jack. …

- Drain the Hydraulic System. …

- Remove the Lower Lever. …

- Pull the Valve Cartridge Out. …

- Fill with Hydraulic Fluid.

Full Answer

How do you fix a pallet jack that won't lift?

How To Repair A Pallet Jack That Won't Lift. Drain The Fluid: Locate the drain screw on the lower right side of the hydraulic pump, near the rear tire. Put a small bucket under the stem of the drain screw, then use an Allen wrench to pull the screw out. This allows the hydraulic fluid to drain from the system.

What causes hydraulic fluid to leak out of a pallet jack?

Although the hydraulic system is usually tightly sealed, a worn, damaged or cracked o-ring by the valve cartridge could allow air to seep through. If you're seeing moisture or hydraulic fluid leaking near the bottom of the pallet jack handle, that's a sure sign that you have a damaged o-ring.

How do you flush hydraulic fluid out of a hydraulic jack?

Put a small bucket under the stem of the drain screw, then use an Allen wrench to pull the screw out. This allows the hydraulic fluid to drain from the system. You may need to pump the handle of the jack up and down a couple of times to flush the rest of the fluid out.

How do you fix a hydraulic pump that won't start?

A simple fix before you take anything apart is to try and remove the air by pumping the handle. Make sure no weight is on the forks. You will want to pump the handle 15-20 times. This will bleed air out of the pump and the hydraulic system will now be filled with fluid only.

How do you fix a pallet jack that won't go up?

0:071:06Pallet Truck Does Not Lift Or Raise? - Troubleshooting Guide 101YouTubeStart of suggested clipEnd of suggested clipPlease try the following ensure. The trigger on the handle is in the correct position for liftingMorePlease try the following ensure. The trigger on the handle is in the correct position for lifting this is its lowest position when it cannot be pushed down any.

Why is my pallet jack won't go down?

Manual Pallet Jacks Won't Lower There are two things that can cause this. The first is actually that there could be too much hydraulic oil in the device. So the first thing to try is to release a little oil from the hydraulic mechanism and try lowering the jack again.

How does a pallet jack pump work?

0:021:28How to Use a Pallet Truck - YouTubeYouTubeStart of suggested clipEnd of suggested clipThe down position allows the user to raise the forks by pumping. The neutral position is used whenMoreThe down position allows the user to raise the forks by pumping. The neutral position is used when moving the load holding the lever in the up position lowers the load.

How do you fix a pallet jack on a hand?

0:001:14fix BROKEN pallet jack handle (how it all works) disassembly - YouTubeYouTubeStart of suggested clipEnd of suggested clipPut the lock washer. And nut back on tighten up the three bolts on a handle.MorePut the lock washer. And nut back on tighten up the three bolts on a handle.

How do you bleed air from a pallet jack?

0:091:32How to bleed the air out of the hydraulic unit on a Pallet jackYouTubeStart of suggested clipEnd of suggested clipSo the first thing you want to do if you haven't checked in a while is remove the fill plug on theMoreSo the first thing you want to do if you haven't checked in a while is remove the fill plug on the front of the reservoir. You'll want to check the oil level.

What kind of hydraulic oil goes in a pallet jack?

A pallet truck/jack is recommended to use a hydraulic oil of viscosity 30cSt at 40°C. If an oil with different viscosity used, one might find it difficult to pump the pallet truck's handle.

How does a hydraulic pump work?

Hydraulic pumps convert electrical energy into fluid pressure by using an electric motor to drive the pump. They are necessary for all hydraulic drives. The fluid pressure is then delivered by hydraulic fluid to cylinders and actuators and hydraulic motors at the required pressure level and volume.

How do you inspect a pallet jack?

Inspect the cart, hand truck or pallet jack closely before each use. Look for cracks and other signs of possible defects or damage. Ensure the wheels are working properly and you have adequate tire pressure. Before operating a pallet truck, check the brakes, steering, controls, forks, hoists and warning devices.

What are the parts of a pallet jack called?

Hand Pallet Jack Anatomy Starting from the top of the pallet jack, there is the handle and control lever. These are used for manual moving, lifting, and lowering of the pallet jack. The handle can be rotated left and right to adjust the direction of the steer wheels, changing the direction of travel.

Can pallet jacks be repaired?

If your pallet jack has a leaky o-ring, the only way to fix it is to replace the ring and then fill the hydraulic system with fluid again. You can get replacement o-rings from most industrial equipment suppliers, tool supply centers and similar sources.

How do you adjust a Crown pallet jack?

7:4810:27Replace the handle on your Crown pallet jack - YouTubeYouTubeStart of suggested clipEnd of suggested clipYou want to lift up on the control rod at the base this will pull the barrel nut up out of theMoreYou want to lift up on the control rod at the base this will pull the barrel nut up out of the control lever and allow you to turn it you want to turn it down about two revolutions.

Should you push or pull a pallet jack?

Pallet jacks are common in the retail industry for moving freight. The sight of one should trigger the memory of a basic safety rule. A person can push almost four times the weight they can pull. That's why when the choice to push or pull a pallet jack arises, it's generally safer to push it.

What are the functions of the buttons found on the handle of an electric pallet jack?

There are two buttons located on both sides of the handle. The inside one is for lowering the forks. The outside one is for raising the forks. When operating, always make sure the load being lifted is within the load- ing capacity of your electric pallet truck and the load has been stacked safely on the pallet.

How do you use a manual pallet jack?

Here are the four simple steps for using a manual pallet jack.Locate Release Lever. ... Move to the Pallet and Press the Lever. ... Slide the Prongs Under the Pallet to Load. ... Jack Up the Pallet. ... Unplug and Store Cord. ... Identify the Controls and Lower Prongs. ... Load the Pallet. ... Use the Control Buttons to Move.More items...•

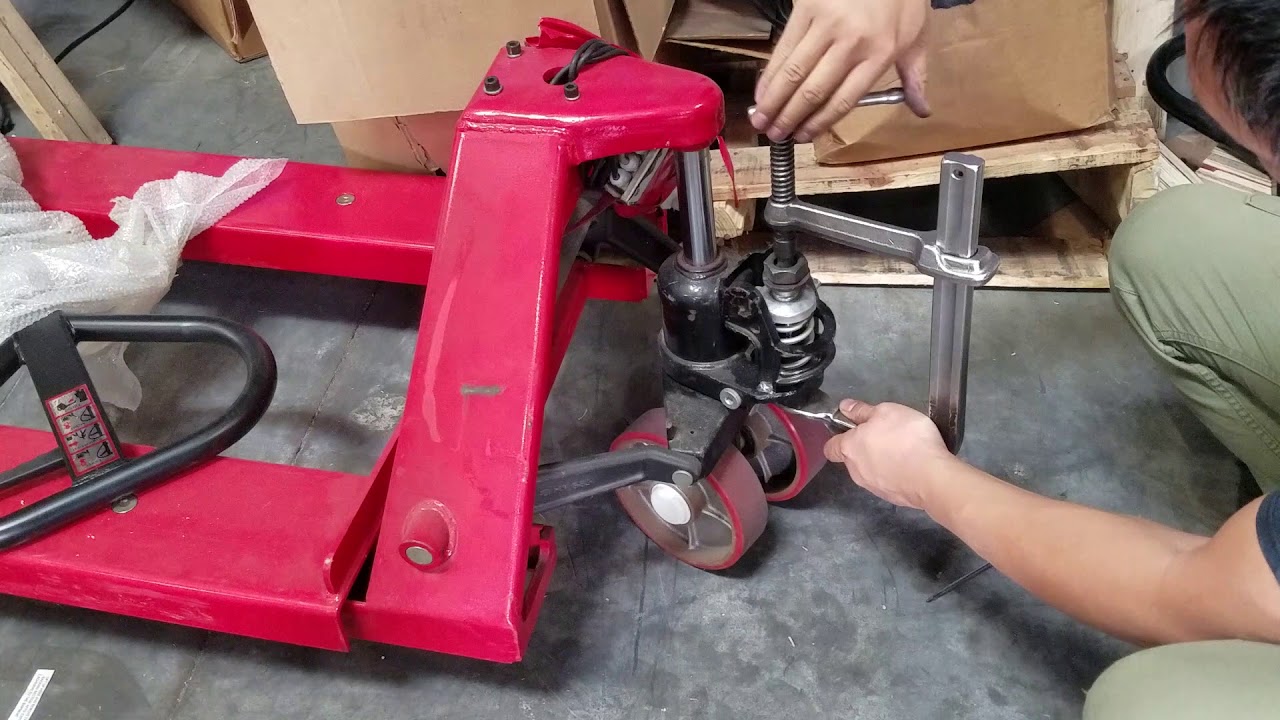

How to reassemble a pallet jack?

Reassemble The Pallet Jack: Put the lowering lever back in place, then insert the retaining pin to keep it there. Tap the retaining pin into place using the screwdriver and hammer if necessary.

Why does my pallet jack stop lifting?

What Causes a Pallet Jack to Stop Lifting? The most common reason for a pallet jack to stop lifting properly is an air pocket in the hydraulic system. Since the hydraulic pressure is what's required to operate the jack, any air pocket can disrupt that pressure and keep the jack from lifting.

How to remove a valve cartridge from a pump?

Pull the lever off the pump body. Remove The O-Ring: Locate the valve cartridge that was covered by the lower lever. Use pliers to turn the valve cartridge counterclockwise. Once it's loose enough, unscrew it the rest of the way and remove it by hand.

How to tell if pallet jack has a cracked o-ring?

If you're seeing moisture or hydraulic fluid leaking near the bottom of the pallet jack handle, that's a sure sign that you have a damaged o-ring.

What is pallet jack?

Categories: , Articles. Pallet jacks are a staple of warehouse equipment, particularly for moving shipping or storage pallets around. Although pallet jacks are fairly compact in size, what they lack in structure is compensated by force.

Is a pallet jack fail proof?

When you're regularly rotating stock or unloading shipments, they are a worthwhile investment. Unfortunately, they aren't fail-proof. If your pallet jack stops lifting, it's important to know how to deal with it. Here's a look at what you should know about a grounded pallet jack.