Printed Circuit Board Repair Process Step-1 Using a Multimeter, identify the faulty component. As I told earlier you need little experience and practice to understand how a circuit and electronic components work. With little training and practice anyone can do it easily. Step-2 Using a Soldering Iron, remove the faulty thru-hole component.

- Fix PCB to your work surface then remove the damaged parts. ...

- Clean the track and remove solder. ...

- Place your copper tape over the track. ...

- Solder the joints. ...

- Restore the circuit board through-hole. ...

- Place and solder your component. ...

- Trim excess tape from the repaired area.

How to properly clean printed circuit boards?

- Disconnect all circuit board connections before cleaning.

- Remove all power sources like power adapters and batteries.

- Avoid using tap water and keep your hands dry at all times.

- While using isopropyl alcohol, wear gloves to protect your hands.

- Handle the circuit board and all its parts gently since it can be quite fragile.

How much does a printed circuit board cost?

Printed circuit boards have a huge range of quality, reliability, complexity, and price points. A circuit board typically costs from 50 cents to $300 dollars to produce, depending on your needs. The price to produce a circuit board has many different factors, and may depend on the number layers, complexity, quantity and components included on the board.

How to repair damaged printed circuit board pads?

The list of these elements are as follows:

- Clean, lint-free cloth

- Flux

- A microscope and if you have magnifying glasses then it works wonders

- Soldering iron and solder

- C-clamps

- Handful of Toothpicks

- Wipes and isopropyl alcohol

- A safe, flat- polished ESD cutting surface

- X-Acto knife

- Adhesive copper tape

How do you troubleshoot a circuit board?

- Visual inspections — You can see a lot through a visual inspection. ...

- Physical inspections — With the board under load, a physical inspection may yield additional insights. ...

- Component testing — Delving deeper into the PCB’s many components, you can test the integrity of batteries, capacitors, resistors, inductors, diodes, switches, and transistors. ...

How do you fix a broken printed circuit board?

How to Repair Damaged Printed Circuit Board PadsStep 1: Tidy Up the Damaged Track 1: ... Step 2: Tidy Up the Damaged Track 2: ... Step 3: Exposing the Track: ... Step 4: Sticking Copper Tape Over the Exposed Track: ... Step 5: Soldering the Copper Tape Joints: ... Step 6: Pierce to Make the Hole: ... Step 7: Solder in Your Component:More items...

How do you fix a fried circuit board?

Most circuit boards are not designed to be able to fix them. It's something simple like a poor solder joint. If you want to, go for it. If magic smoke has escaped from a robotic built board, you should replace it.

Can soldering iron damaged circuit board?

Burns happen when the iron is too hot. Unmasked boards seem more vulnerable than solder masked boards. Loosened traces/pads and solder mask damage happen when you apply too much force with the soldering iron (trying to get that stubborn lead loose). Warping of the PCB is possible but you have to try hard.

Can you repair a burnt circuit board?

Nevertheless, the damage can be repaired and the board restored to it original integrity - and even appearance - by the following procedure. Some specialized tools are needed, and the liquid epoxy repair material can even be colored, with color agents to replicate the color of the surrounding original board material.

Can a circuit board be fixed?

Luckily, it's possible to repair or remanufacture boards to make them like new again. This does one of two things. Either the board in question can be returned to its original device, making it function again. Or, it can be used in a completely different device, as a form of recycling if you will.

What kind of solder do I use on a circuit board?

2.1 Best Solder For Circuit Board—The Lead-based Solder The lead alloy solder has been an industry standard for a long time. It contains a mixture of tin and lead in a percentage of 60/40. The melting temperature for this compound is between 180-190 degrees Celsius.

What is the best solder for circuit boards?

6 Best Solder for Electronics ReviewsKester Solder. First on our list is the Kester Solder, a 0.031 inches diameter steel-based solder with very high conductivity. ... Maiyum Solder Wire. ... SONEAK 60/40 Tin Lead Solder. ... Austor Solder Wire. ... Canfield Solder. ... Mandala Crafts Store Rosin Core Solder Wire.

How do you fix bad solder on a circuit board?

1:382:54How To Fix Bad Solder Joint On Circuit Board (Using ... - YouTubeYouTubeStart of suggested clipEnd of suggested clipI will again for the tip at an angle until it's all melted. And use a solder sucker. And there youMoreI will again for the tip at an angle until it's all melted. And use a solder sucker. And there you see that the old solder has been sucked up.

What causes a circuit board to fry?

Boards might burn because of poor protections. The lack of properly sized fuse protection should be number one priority. A high voltage protection diode protects the board from burning in the event of a lightning strike or other voltage surges. Other reasons for board burning are related to technician error.

How do you know if a circuit board is fried?

Physical Damage Smelling smoke or seeing charred circuitry are obvious signs, but also examine the capacitors, which are cylindrical in shape and placed in various locations on the board. Their job is to filter the electricity going to various components on the board, and power surges or overheating can damage them.

Can a fried phone Be Fixed?

Take Your Water Damaged Phone to a Trusted Repair Shop If the phone is completely fried (it won't turn on), check to see if you still have warranty for it. If you do, great. If not, you might have to bite the bullet and send the device to the manufacturer to repair it. That usually comes with a fee.

Can you fry a circuit board?

circuit boards are the core electronic wiring for most modern electronics, and to fry the circuit board means to severely damage your device. Circuit boards are composed of a fiberglass board woven with copper wire or other conductive materials.

How to get solder resist off PCB?

Scrape a little of the solder resist off with a knife, sharp screwdriver or fine sandpaper. Ensure that the exposed track is clean and shiny. It is also a good idea to clean any residual burnt PCB material off, to allow the tape to stick well.

What happens if a PCB is overheated?

If a PCB is overheated the most likely outcome is that the copper layer will de-laminate from the fibreglass board. This usually leads to broken joints and a non-working circuit. It is possible to repair some faults using adhesive copper tape and solder. Ask Question.

What is a PCB made of?

Printed Circuit Boards (PCB) are made from layers of fibreglass and copper, glued together. Whilst the glues used are very heat resistant it is possible to overheat a PCB and damage it. Kitronik PCB designs use large tracks and pads to help make this a rare problem, the larger amount of copper helps to dissipate the heat.

Can copper tape be cut?

The Copper tape can be cut to size with scissors, craft knife etc. Once a repair has been made it is also possible to trim the excess tape. If this is done exercise caution, as the repair is more fragile than the original PCB track, and may become unstuck again.

Does copper tape melt?

Carefully solder the joint (s) where the repair has taken place. Most copper tape adhesive melts at soldering temperatures, so be quick and use as little heat as possible. When the tape cools the adhesive will usually remain sticky.

How to fix a broken PCB?

Step 1. Mix the epoxy according to the manufacturer's instructions, and apply it sparingly to one side of the PCB. Press the two halves of the broken board together, and hold them until the epoxy takes hold. The epoxy will set in a few seconds, but you should wait for thirty minutes before proceeding to the next step.

How to clean a soldering pencil?

Plug the soldering pencil into a 110-volt receptacle and wait for it to get hot. Clean the hot soldering tip by wiping it on a wet soldering sponge. Make sure to remove all the dirt and oxidation from the tip.

How to remove copper traces from a sanded sandpaper?

Cut through the broken copper traces using a razor knife. Remove all of the loose traces, and then carefully use the emery cloth to sand the traces from which you removed the loose sections. Sand the ends of these traces until the bright copper shows clearly.

How to fuses copper wire?

Pick up a piece of tinned wire with the tweezers and lay it carefully across one of the traces where you removed a loose section. With the piece of wire lying across the gap, touch the soldering pencil's tip to the top of the wire until it fuses to a copper trace on the board. Repeat this step with the remaining wires.

What color should a tinned solder tip be?

A properly tinned tip will be a bright silvery color. If the tip is a dull gray color, you will need to repeat steps 3 and 4 until you achieve a properly tinned tip. This is necessary for the efficient transfer of heat during the soldering process.

Can you repair a PCB?

Although it's sometimes possible to repair a broken PCB, it can be an extremely frustrating process.

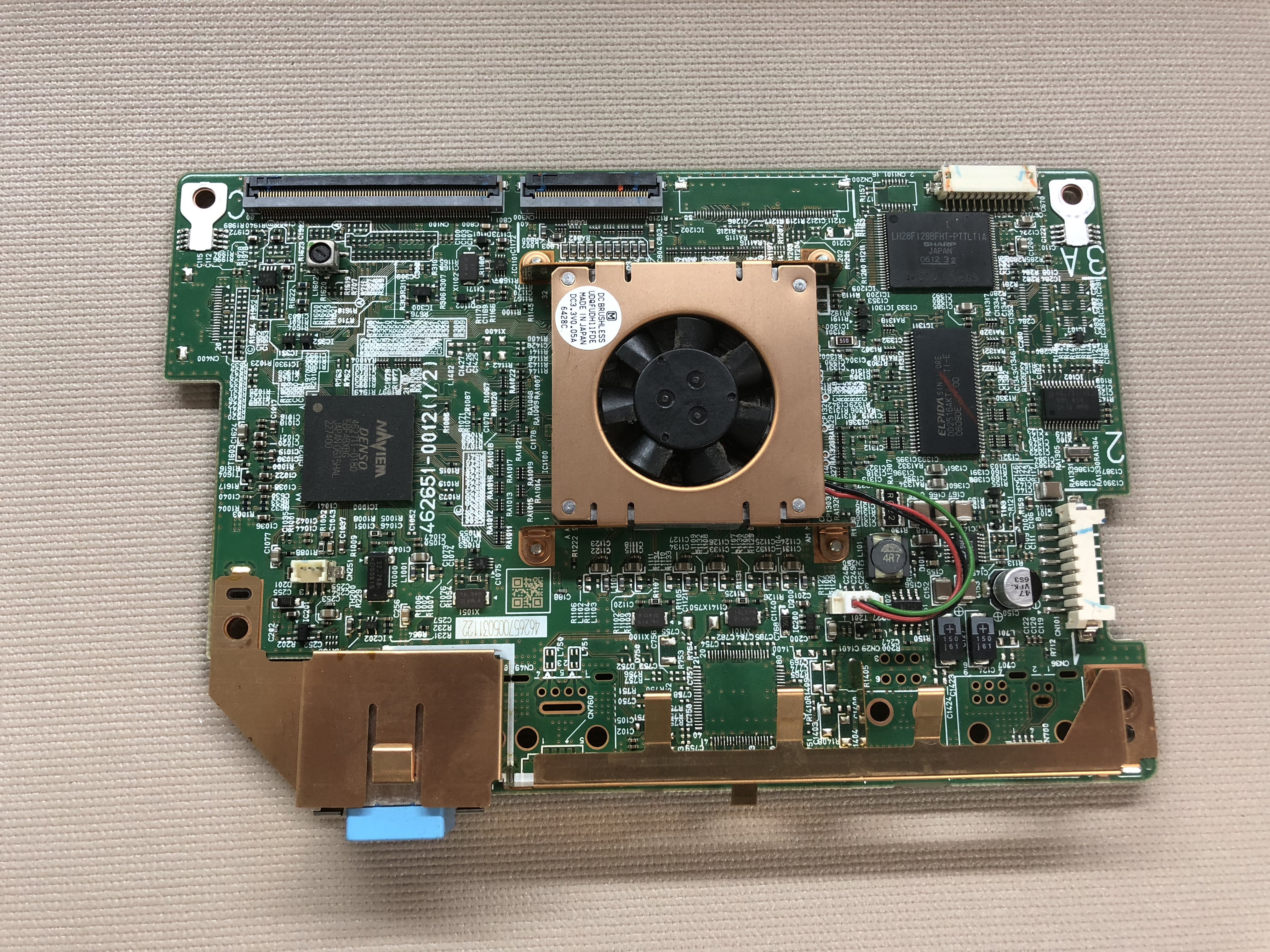

Why do printed circuit boards fail?

Can PCB be repaired? How to fix the PCB board? What materials are needed for PCB board repair? Before clarifying these problems, we need to know the reasons for the damage to the printed circuit board.

What materials are necessary for PCB board repair?

Most printed circuit board repairs require the same or improved materials used in the official design. If you are searching for "electronic board repair near me," please contact us. Our PCB repair services and the team can help you reassemble or repair the damaged circuit board to make it close to its original state.

How to repair electronic circuit boards?

The electronic circuit board repair is most commonly after thermal and physical damage and excessive voltage to the components. So, how to repair broken circuit boards step by step?

How to replace thru hole component?

To Replace a faulty thru-hole component, insert the component in the holes. Apple Flux at the Junction of the Hole and Component Lead. If you are Using Flux-Cored Solder Wire then there is no need to use flux. Now using the solder wire and soldering iron do the hand soldering.

How to replace a faulty SMD?

To Replace a faulty SMD component, apple Flux on the circuit and then apply Solder Paste. Hold the component at place using a Tweezers and Apply Heat using a Hot Air SMD Rework Station. Solder paste will melt and form solder joint. Don’t worry there won’t be any solder bridging.

What is a desolder wire?

Desolder wire or wick is used to remove excess solder that remains on the board. PCB Holder and Magnifying Lamp: A PCB Holder is used to hold the PCB form easy of soldering and desoldering. A magnifying lamp is used to see tiny components enlarged. Multimeter: A multimeter is needed to check the Tracks and Faulty Components.

Why is my circuit board failing?

Aside from physical damage, faulty components are the other most common cause of printed circuit board failures. In fact, if and when there is no physical damage but a device has failed to operate or power on, you can almost guarantee it has to do with one of the components connected to the board.

What causes PCB failure?

1. Physical Damage. This is the more obvious choice when it pertains to the damage of a circuit board. In fact, the most common causes of PCB failures all stem from physical damage to a device or its internals. This can be just about anything pertaining to physical pressure or shock.

What is the substrate for PCB?

It may call for copper or silver to be reseated to repair trace pathways. PCB substrates are often comprised of fiberglass or an epoxy resin with copper foil bonded to the conductive layer.

What is a PCB in a coffee maker?

Everything except the simplest of electronics uses a board of some kind to connect and mechanically sync all elements of the product. A coffee maker, for instance, might have a small PCB inside to connect the electronic control system, heater element and display.

What are PCB components?

Those “components” include things like the battery, resistors, LEDs, transistors, capacitors and more. Boards are often produced in layers, which include various levels of conductive and non-conductive sheets.

How do PCBs work?

Today, it’s all done via design and manufacturing software. PCBs are mechanically necessary to support and connect all components within the device, which are synced using conductive tracks—this allows electricity to flow freely through the board and from component to component.

What is the PCB in a phone?

Inside the device are several pieces that house and connect the necessary components. One of those core pieces is called a printed circuit board or PCB for short.

What is PCB design?

In hardware development of electric al circuit, to get all the components of circuit on one single place or board is called PCB designing. Printed Circuit Board (PCB) is the common name that is used for these electrical boards. In history, PCBs were been developed by going through a complicated procedure of point-to-point wiring ...

What is the power of a PCB?

Before getting into details of printed circuit board (PCB), there are some basics you need to know about circuits. Electricity: It is the power provided to every instrument ranging from small lights to heavy machinery. Electricity is just a flow of electron from one level to other (upper level to lower mostly).

Why are PCBs multi layered?

Older PCBs were single layered but these days multi layer PCBs are present and used in the market .PCBs are multi layered because these days complexity of electrical circuit is also increased.

What are the elements of an electrical circuit?

Voltage, current, resistors, capacitors and inductors are considered as primary elements of any electrical scenario called circuit. Electrical current can be in two forms either a sinusoid AC (alternating) current or simply a straight line called direct or DC current. In hardware development of electrical circuit, ...

What is the second stage of a circuit?

Second stage is to detect location of the faults. It deals with minute analysis to pinpoint the faulty component. But not like functionality test it performs tests only on input and output stages. In third stage new functional components are placed in circuit after removing the faulty components.