Repairing a Damaged Pad on a PCB

- Step 1: Cleaning. Clean the damaged are with isopropyl alcohol and blow dry with canned or compressed air or damp dry...

- Step 2: Remove the Damaged Pad. Carefully cut away with an Exacto knife the damaged pad.

- Step 3: Clean Up the Area in Around the Pad.

- Step 4: Remove Mask.

- Step 5: Clean. Clean the area using isopropyl alcohol and dry...

- Step 1: Cleaning. ...

- Step 2: Remove the Damaged Pad. ...

- Step 3: Clean Up the Area in Around the Pad. ...

- Step 4: Remove Mask. ...

- Step 5: Clean. ...

- Step 6: Tin the Conductor. ...

- Step 7: Sise Up and Select the Right Circuit Frame. ...

- Step 8: Tin the Replacement Pad/Conductor.

How do you fix a ripped PCB pad?

Drill small hole near the ripped pad and insert a piece of copper. Twist the ends of the copper so that they form 2 loops on both ends of the board. Then solder it to the track and on top of that solder any component that was there.

How to solder into a broken PCB pad?

Well, if the pad has a trace on either side of the board, you can just run a wire to the next place to solder into that trace. If the monster is immortal, either it does not exist, or there are two. you could connect your cap with another component in ur pcb by using a wire. No trace on the broken side.

How do I fix a damaged pad on my keyboard?

· Cleaning the damaged pad: Thoroughly clean the damaged area with isopropyl alcohol, and follow up by drying the area with a lint-free cloth or compressed/canned air. · Removing the damaged pad: Use an X-Acto knife to carefully cut away the damaged pad.

How can I repair a broken pad from a broken switch?

I'd try first gluing down the torn-off pad in its original place. (Carefully unsolder it from the switch, without bending it, then glue it down using a tiny droplet of crazy glue.) Then, use solder to "tin" the scraped copper trace, then solder a tiny wire from the glued pad to the trace. Finally, solder in the new switch.

How do you fix a ripped PCB pad?

5:0010:17How To Repair Damaged /Missing PCB Pads - INVISIBLE Fix #solderingYouTubeStart of suggested clipEnd of suggested clipOver a little bit solder put it put the solder on your iron before you do. This. So just a littleMoreOver a little bit solder put it put the solder on your iron before you do. This. So just a little bit of solar on the other. End. And you've got a nice little bridge.

How do you repair a ripped solder pad?

1:006:02How to Bypass Missing & Broken Solder Pads - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo we can just solder directly to that but getting to it will take a little bit of patience. AndMoreSo we can just solder directly to that but getting to it will take a little bit of patience. And finesse. So for a start use a sharp craft knife to scratch away the silk screen on top of the trace.

Can PCB board be repaired?

Luckily, it's possible to repair or remanufacture boards to make them like new again. This does one of two things. Either the board in question can be returned to its original device, making it function again. Or, it can be used in a completely different device, as a form of recycling if you will.

How do you fix a broken PCB contact?

How to Repair Damaged Printed Circuit Board PadsStep 1: Tidy Up the Damaged Track 1: ... Step 2: Tidy Up the Damaged Track 2: ... Step 3: Exposing the Track: ... Step 4: Sticking Copper Tape Over the Exposed Track: ... Step 5: Soldering the Copper Tape Joints: ... Step 6: Pierce to Make the Hole: ... Step 7: Solder in Your Component:More items...

How do you fix a PCB hole?

0:000:31CircuitMedic Plated Hole Repair Kit for damaged plated through holes ...YouTubeStart of suggested clipEnd of suggested clipPlated holes and circuit boards are easily damaged. When you find the need to make repairs theMorePlated holes and circuit boards are easily damaged. When you find the need to make repairs the plated hole repair kit has all the tools and materials for the job.

How do you repair a PCB board?

Fix PCB to your work surface then remove the damaged parts. ... Clean the track and remove solder. ... Place your copper tape over the track. ... Solder the joints. ... Restore the circuit board through-hole. ... Place and solder your component. ... Trim excess tape from the repaired area.

What is a pad on a circuit board?

A pad is the exposed region of metal on a circuit board that the component lead is soldered to. Multiple pads in conjunction are used to generate the component footprint or land pattern on the PCB. The two types of pads available are through-hole and surface mount pads.

Can soldering damage PCB?

Using soldering with recommended temperature won't damage the board.

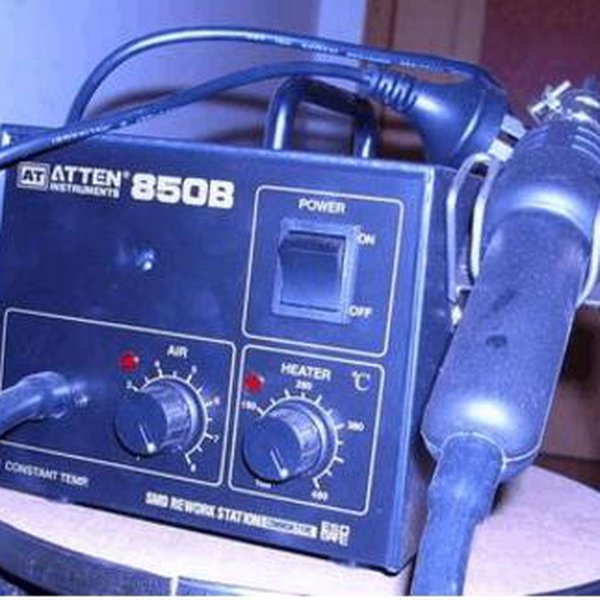

Which tools should be used to replace damaged components on the PCB?

Goot Soldering Iron is the Best. Desoldering Pump and Desolder Wire: A soldering iron is used to melt solder from leads of the faulty component and this molten solder then sucked-in using a desoldering pump. Desolder wire or wick is used to remove excess solder that remains on the board.

Can you glue a circuit board back together?

0:298:09How to Repair a Cracked or Broken Circuit Board - YouTubeYouTubeStart of suggested clipEnd of suggested clipBoard is to glue the two halves. Back together. And what I used here was a special plastic bondingMoreBoard is to glue the two halves. Back together. And what I used here was a special plastic bonding epoxy it seems to stick real good to two circuit boards. And it's called plastic fusion by superglue.

How do you solder a pad?

0:433:28How to Solder - Fill the pads with solder - YouTubeYouTubeStart of suggested clipEnd of suggested clipAfter you clean the soldering iron add a tiny bit of solder to the tip. So you can see where the hotMoreAfter you clean the soldering iron add a tiny bit of solder to the tip. So you can see where the hot part is touch the pad. And when the pad is hot enough add the solder to the pad.

How do you know if your PCB is damaged?

How to Know if a PCB Is Bad? Test the PCB with the power on, if electronic components are installed. ... Remove any power source from the PCB if one exists. ... Look for scratches, burn marks or misplaced solder. ... Ground the board at one of the screw holes for mounting using a ground lead provided with your tool.More items...•

How do you know if PCB components are bad?

Instructions Turn off any power to the circuit before examining the board. ... Check the circuit board for fuses. ... Examine components on the board for signs of physical damage. ... Turn the digital multimeter on and set it to its diode test function.More items...•

How do you reset a PCB board?

0:453:04How to reset your circuit board - YouTubeYouTubeStart of suggested clipEnd of suggested clipWater as you can see this switch here has tripped.MoreWater as you can see this switch here has tripped.

How to get solder resist off PCB?

Scrape a little of the solder resist off with a knife, sharp screwdriver or fine sandpaper. Ensure that the exposed track is clean and shiny. It is also a good idea to clean any residual burnt PCB material off, to allow the tape to stick well.

What is a PCB made of?

Printed Circuit Boards (PCB) are made from layers of fibreglass and copper, glued together. Whilst the glues used are very heat resistant it is possible to overheat a PCB and damage it. Kitronik PCB designs use large tracks and pads to help make this a rare problem, the larger amount of copper helps to dissipate the heat.

Can copper tape be cut?

The Copper tape can be cut to size with scissors, craft knife etc. Once a repair has been made it is also possible to trim the excess tape. If this is done exercise caution, as the repair is more fragile than the original PCB track, and may become unstuck again.

Can you repair a fault with solder?

It is possible to repair some faults using adhesive copper tape and solder.

Does copper tape melt?

Carefully solder the joint (s) where the repair has taken place. Most copper tape adhesive melts at soldering temperatures, so be quick and use as little heat as possible. When the tape cools the adhesive will usually remain sticky.

Step 1: Cleaning

Clean the damaged are with isopropyl alcohol and blow dry with canned or compressed air or damp dry with a lint free cloth.

Step 5: Clean

Clean the area using isopropyl alcohol and dry via compressed or canned air or a lint free cloth.

Step 6: Tin the Conductor

Using the correct type of solder alloy tin the conductor area in place where the new conductor will be attached

Step 7: Sise Up and Select the Right Circuit Frame

Select the new conductor from the circuit frame. Cut out with sharp small knife.

Step 10: Clamp and Cure

Hold the replacement pad/trace in place until cured. Remove the clamp. Clean with isopropyl alcohol and inspect. I also like to perform a quick electrical continuity check at this point. In some cases I even envelope the edges of the replacement pad/trace with solder mask or epoxy and cure so that it has extra mechanical strength.

What to do if you do try drilling?

If you do try drilling, get a pin vise and some really tiny bits. Don't try drilling with a regular drill. Too much potention for real damage.

Can you run a wire to the next place to solder into a trace?

Well, if the pad has a trace on either side of the board , you can just run a wire to the next place to solder into that trace.

Can soldering be used on through hole plating?

I don't understand the suggestion of soldering to the through-hole plating - it's no use unless there is still a trace connected to it, and the trace will be broken if it's on the side where the pad lifted off.

Can you glue wire down to pull off?

It wont be pretty, but it will work. You can glue the wire down in a couple places so it doesn't get pulled out and cause any problems.

Can you solder a through hole?

If you didn't, you can just apply some Good Flux and probably still solder to the through-hole.

How to solder a lead pad?

Use good soldering technique. Heat both the lead and the pad, apply solder anywhere but the iron. I apply solder from the opposite side where I'm placing the iron.

How to hold copper to board?

The copper is held to the board by an adhesive that melts when too much heat is applied. Plated through holes will help prevent pads from lifting. On single sided boards, or double sided without plated through holes, it's important to avoid using too much heat and to remove as much solder as possible before trying to move the component lead. Remove solder, let any remaining solder cool, break any remaining mechanical connection with an appropriate tool, then remove the lead. When removing solder, apply any mechanical stress in a direction where the trace attached to the pad (edited to replace trace with pad) will provide some mechanical support, e.g. away from the trace, not towards.

How many solder joints do you need for a solder joint?

2. The adhesive itself is an insulator, so you need two solder joints. One to the component and one to the broken trace. Which adds more heat into the mix.

How to expose copper on a trace?

Then put the wire through the hole but strip the wire insulation enough the the wire will reach the exposed trace. Then solder to the trace, afterward you can apply some nail polish over the joint if you want, to replicate the solder resist. Like said others may do it differently.

Why do you need paragraphs in a post?

Paragraphs would make your post more readable .

Can you pad lift with soldering?

On poor quality boards, or those that skimp on pad area, pad lift happens even with good soldering technique.

Can you repair a pad lift?

Repair for pad lift like that on a single sided board isn't very complicated. You could use adhesive backed tape if you wanted to restore the pad.