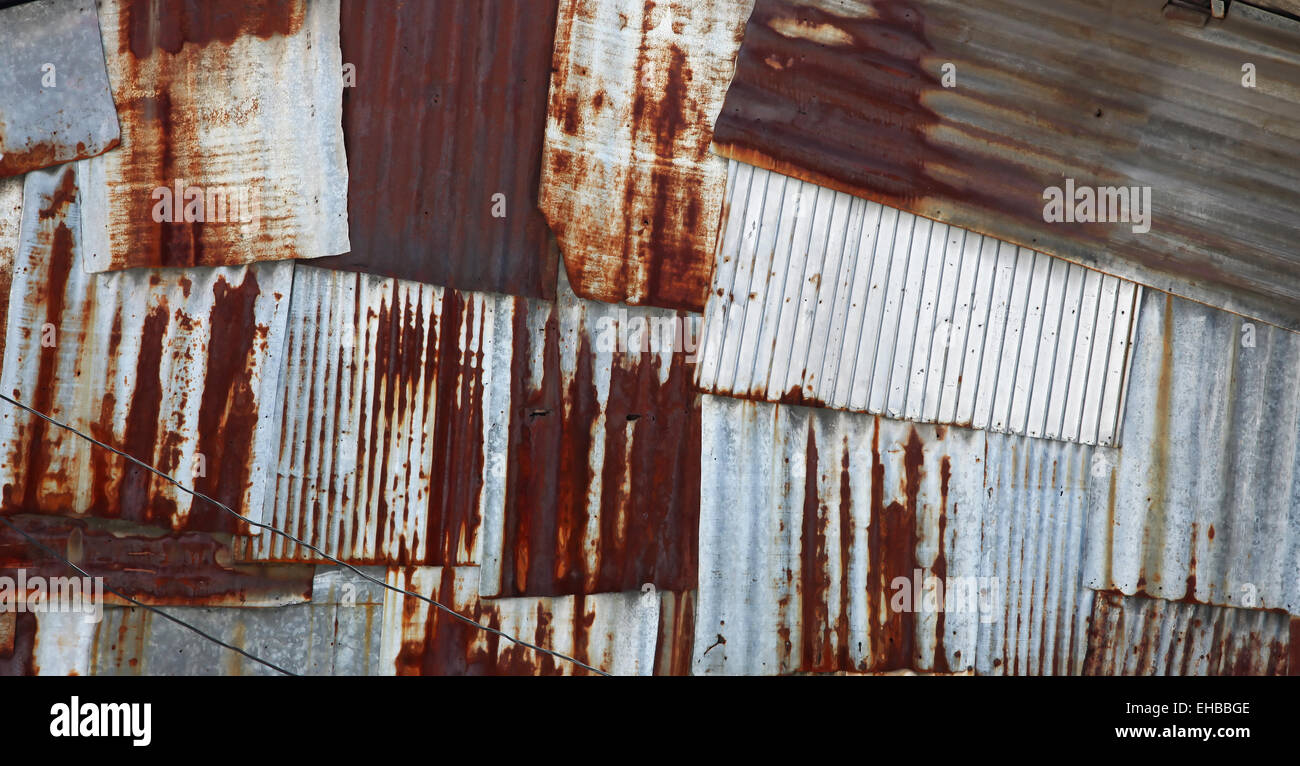

How to Repair Galvanized Metal Rust

- Apply vinegar to the rust. Pour some vinegar on a wire brush, then scrub the rusted area thoroughly.

- Wash the area with a garden hose to neutralize the acids in the vinegar. Examine the area for stubborn rust stains.

- Put on protective plastic or rubber gloves and safety goggles, then open the Naval Jelly. ...

- Paint the mixture onto the rusted areas. Allow to sit for 10 minutes, then immediately rinse the solution from the surface of the metal.

- Apply a zinc-rich paint over the repaired area. Select a paint that matches the existing color of the metal as closely as possible.

- Apply vinegar to the rust. ...

- Wash the area with a garden hose to neutralize the acids in the vinegar. ...

- Put on protective plastic or rubber gloves and safety goggles, then open the Naval Jelly. ...

- Paint the mixture onto the rusted areas. ...

- Apply a zinc-rich paint over the repaired area.

How do you remove rust from galvanized metal?

To protect the integrity of the item, repair galvanized metal rust as soon as it is noticed. Apply vinegar to the rust. Pour some vinegar on a wire brush, then scrub the rusted area thoroughly. Wash the area with a garden hose to neutralize the acids in the vinegar.

Why does galvanized steel rust?

Galvanized steel is designed not to rust, so if you have a galvanized steel item that has rusted, it means that the galvanization has worn off completely in those areas. Galvanization involves zinc, which corrodes instead of the actual metal to prevent rust. When the zinc is all gone, this is when real rust sets in.

How to repair galvanized steel?

Spraying with molten zinc (metalizing) The touch-up and repair method chosen should consider the specific use of the galvanized steel and the performance characteristics of each of the three methods.

Can you paint over galvanized steel?

Under very rare circumstances, trace contaminants in solvents used in the cleaning process can damage the zinc coating on galvanized steel. For large pieces of damaged galvanized steel, the recommended procedures are applying zinc-rich paint or zinc-rich solder.

How do you restore rusted galvanized metal?

Step by Step Instructions for Galvanized MetalIn a bucket, mix 2 gallons of water and a half cup of dish soap.Dip a bristle brush in the mixture.Use circular strokes to scrub the surface.Rinse and dry with cloth.Apply a bit of metal polish to a cloth.Rub in small circles.Wipe and enjoy that shine.

Can you paint over rusted galvanized metal?

Removing rust is an important first step because if the rust is not removed it continues to spread creating rust-holes that are difficult and expensive to repair. Once all the rust is gone from the galvanized metal, then you can paint it.

How do you seal rusted galvanized metal?

After a light sanding and dusting off, apply some rust neutralizer with a brush or try a rust neutralizer spray in a can. It will seal in the rust and create a tough polymer coating that is ready for primer and paint. You can work quickly because the rust neutralizer dries in just 20 minutes.

Can you restore galvanized steel?

Once dry, the metal, usually iron or steel, is protected from corrosion and rust. The surface of galvanized metal is usually shiny, but over time the shine can become milky or cloudy. You can restore shine to galvanized metal by removing the build-up that causes cloudiness.

What paint will stick to galvanized metal?

What paint will stick to galvanized metal? Once the galvanized metal is cleaned thoroughly, most acrylic paints will adhere to it without any issues.

Can I use Rust-Oleum on galvanized metal?

Rust-Oleum® Stops Rust® Latex Aluminum Primer provides excellent adhesion on aluminum and galvanized surfaces, and it cleans with soap and water.

How do I stop rusting but keep the look?

Step 1: Penetrol He recommended a product called Penetrol normally used as a paint additive to improve flow and adhesion that also seals and stops rust. It can be used alone as a base coat on bare metal and will fix the rust while preserving the appearance.

How do you neutralize rust before painting?

All it takes is a pass with a soft cloth dampened with a homemade degreasing solution—four teaspoons liquid dish soap mixed in one gallon of warm water—followed by a “rinse” using a water-dampened rag. Let the metal air-dry completely before breaking out the primer.

Will rust stop if sealed?

By sealing out moisture, using a rust converter extends the life of metal and prevents future corrosion from occurring.

Can you use CLR on galvanized metal?

We do not recommend using CLR on galvanized metals. When a metal is galvanized, a Zinc coating is put over the metal (usually to protect it from rusting). The acids in CLR will remove the Zinc which could compromise the material.

Can you repair a galvanized?

To replace the damaged section of threaded galvanized water pipe, cut the damaged area using a reciprocal saw. Two cuts should be made with one being several inches from the threaded coupling and the other at one of the threads. This should be done at both ends of the section.

Will vinegar clean galvanized metal?

Like most, you probably already have white vinegar on hand as a cleaning solution for your home. White vinegar is effective and non-toxic which is much safer to use rather than an industrial solvent. All you need to do is apply the vinegar on a clean rag and then simply wipe down the galvanized surface.

How do you paint a rusted galvanized metal roof?

How to Paint a Rusty Metal RoofRemove Rust From a Metal Roof. Removing the rust from your metal roof is going to take some physical work. ... Wipe the Roof Down With Vinegar. ... Apply Primer. ... Apply Paint. ... Final Coat.

What primer should I use on galvanized metal?

Zinc Rich Primers for Mild Steel We stock many professional-use zinc-rich primers that add protection to non-galvanised steel surfaces.

Will spray paint adhere to galvanized metal?

The truth is that paint will not adhere to galvanized steel. The layer of zinc left on the metal after the galvanization process is meant to reduce corrosion, but it also rejects paint, eventually causing it to peel or shed.

Can you sand off galvanized coating?

If you want to remove a galvanized coating without using chemicals, abrasive blasting is an effective method that can get the job done… provided you are using the right blast media. With abrasive blasting, sand or other abrasive particles are propelled through a nozzle with compressed air.

How to get rust off a steel table?

This doesn’t require anything fancy. Pour some vinegar on the rusty spot and then rub off the rust with a wire brush. Rinse off the loose rust and dry thoroughly. Next, make a second pass over the rusted area. If you still see rust, repeat the first step. Then rinse off the steel with a garden hose and allow to dry again.

How to get rid of rust on a car?

Paint the solution of naval jelly and water on the areas of rust. Let it sit for 5 minutes and look for rust. If you see rust, repeat. Rinse and dry the affected surface once you have removed the last of the visible rust.

What happens when metal is exposed to water?

If that metal is underwater or exposed to water on a constant basis for a long time, the zinc coating begins to react with the water and the carbon dioxide in the air to form zinc carbonate, which is off-white. Eventually the zinc carbonate can flake away and expose the steel beneath it.

What is galvanized steel used for?

Galvanized steel shows up in numerous everyday applications. Galvanized steel is even used to touch up boats, storage sheds and chain linked fences. But, when galvanized steel is in constant contact with water, it can develop a kind of corrosion known as white rust.

What do you need to repair a phosphoric acid burn?

Now you can begin your repair process. You will need protective goggles, rubber gloves, and naval jelly. The reason you need the protective gear is that naval jelly is just the common name for phosphoric acid. It’s not really a “strong” acid, but it can still burn your skin and eyes.

Can hot dip galvanized steel be damaged?

Hot-dip galvanized steel is very resistant to damage, but occasionally it is damaged after it leaves the galvanizing plant. Corrosive in-service conditions, rough handling in transit, and faulty installation techniques can cause abrasion of galvanized steel.

Does white rust go away?

If you just let white rust “go,” the surrounding area that is still galvanized will slow down the corrosion – even the part that has lost its coating. But eventually rust will destroy metal if you don’t take care of it.

How to clean rust off galvanized steel?

Step 1. Clean the galvanized steel. Wipe down small pieces of steel using cleaning rags with three drops of liquid detergent in order to remove dirt, dust, grime and sometimes large chunks of rust. Larger items can be pressure-washed or hosed down.

How to get rust off metal?

Scrape off large areas of rust with the wire brush . Use firm pressure and a back-and-forth motion to remove rust from the metal. The wire brush may scratch the metal, but since you will have to paint and re-galvanize it anyway, this is OK. Wear your protective goggles from this point forward to keep rust particles from flying into your eyes.

What to use to remove rust from steel?

If the steel piece is flat and the rusted area is very large, use a belt sander to remove the rust more quickly.

How to restore rusty steel?

Take preventative measures to inhibit further rust. Paint the item (or at least the sanded and scrubbed areas) with zinc-rich paint or cold galvanizing spray to restore the galvanization to the steel. Apply two to three coats of paint, but be sure to allow at least 90 minutes between coats to insure that the area has dried completely.

How to get rid of rust on a sandpaper?

Sand off any remaining rust. Use firm pressure and rub the sandpaper back and forth just over the rusty areas. Do not sand the entire item unless the entire thing is rusty.

Does galvanized steel rust?

Galvanized steel is designed not to rust, so if you have a galvanized steel item that has rusted, it means that the galvanization has worn off completely in those areas. Galvanization involves zinc, which corrodes instead of the actual metal to prevent rust. When the zinc is all gone, this is when real rust sets in. You can remove rust from galvanized steel, but you will need to repair the area that rusted to prevent the rust from simply returning when the metal is again exposed to moisture.

How is galvanized steel made?

Galvanizing of steel sheet is done by a process called “continuous hot-dip,” in which steel sheet is sank into a bath of molten zinc. The liquid zinc helps steel sheet to form a protective layer on steel sheet. The steel sheet can then be fabricated into other shapes with no flake or peeling off.

How to remove rust from a sandpaper?

Rust Removing Method: Use wire brush dipped with vinegar to scrub rusted area completely, apply vinegar to the rust. Pour some vinegar on a wire brush, then scrub the rusted area thoroughly. Then use garden hose to clean vinegar, if there is stubborn rust stains, repeat the process. Then mix water and rust dissolver by the percentage of 95% and 5%.

What is zinc coated steel?

Zinc coated steel sheet and plate product, which is also named galvanized steel sheet, have been used in many fields in our life. A large number of galvanized thin sheets are used in the fields of automobile manufacturing, refrigerators, construction, ventilation and heating facilities, and furniture manufacturing.

Why is zinc plating important?

Zinc plating has become an important method of steel corrosion protection, not only because zinc can form a dense protective layer on the steel surface, but also because zinc has a cathodic protection effect. When the galvanized layer is damaged, it can still prevent iron layer by cathodic protection.

What to use to clean galvanized steel?

Use these items: emery cloth, a wire brush, sandblasting , etc. Cleaning galvanized steel surfaces is often done with a stainless steel wire brush. To ensure a smooth surface result, surface preparation should extend into the surrounding undamaged galvanized coating. Breaking the oxide layer by agitation is an important key to successful galvanizing ...

How to solder a galvanizing rod?

Drag the rod over the area to be soldered, until it begins to flow. Once the rod flows, stop applying the heat. Deposit the desired thickness of galvanizing repair rod. A stainless steel brush works well to spread the solder and ensure it is adhering. If additional layers are needed, continue to drag the rod over the area.

What to do if you stopped soldering?

If you stopped soldering and want to apply more solder or flow out the deposit more, let the area cool below the solid temperature and reheat. The existing coating will help the bonding process, whether adding more solder or just flowing out the previous deposit.

How to apply zinc dust paint?

Spray or brush-apply the paints containing zinc dust to the prepared surfaces/areas. Apply the paint in accordance with the manufacturer’s recommendations in a single application employing multiple passes to achieve a dry film thickness as specified.

Can you clean zinc dust?

Repair surfaces with paint containing zinc dust shall be clean, dry, free of oil, grease, pre-existing paint, corrosion, and/or rust. Clean surfaces in according with the requirements of SSPC SP10 (near-white). Where circumstances do not allow blast or power tool cleaning to be used, then hand tools may be used.

Can you use zinc coating in the field?

This method is not for field application and cannot be used in the field. This method involves the application of a zinc coating by spraying the surface to be repaired with droplets of molten metal using wire, ribbon, or powder processes. Must contact a metalizing shop.

Can galvanized steel be repaired?

Galvanized coatings on steel are routinely damaged during welding, cutting, and transport. They must be repaired, or else the damage will result in rusting. There are three specific ways to repair the coating. Steps.

Does galvanized tub extend life?

Perhaps you want to fix a corroded area or provide additional corrosion protection to a weathered galvanized wash tub. Yes, this will extend the life of the galvanized container. However, once the galvanized zinc coating is significantly deteriorated, it's long useful life is over.

Can you paint galvanized buckets?

The best DIY method to repair and extend the life of galvanized buckets is to paint them. Painting a fully-weathered hot-dip galvanized coa ting is often done successfully with little surface preparation required. The naturally occurring zinc patina forms an adherent profile on the surface of the coating that is excellent for paint systems.

Can you power wash zinc before painting?

The naturally occurring zinc patina forms an adherent profile on the surface of the coating that is excellent for paint systems. It is an industry standard to power wash the surface before applying paint, but a general washing will do.

Why is galvanized steel bare?

Occasionally, small areas of the galvanized article may be bare due to unseen contaiminants the cleaning process is unable to remove. There are methods available to ensure post-galvanizing coating integrity and ASTM A780, Standard Practice for Repair of Damaged and Uncoated Areas of Hot-dip Galvanized Coatings authorizes three accepted touch-up and repair methods:

Is zinc rich paint cold galvanizing?

Applying zinc-rich paint is often erroneously called cold galvanizing, and may be appropriate for touchup and repair but just as is the case for applying any paint, surface preparation procedures outlined in D6386 should be closely adhered to in order to ensure the best overall performance.