- Rough the surface of silicone rubber with sandpaper or steel wool.

- Sand the steel, aluminum or metal first with a coarse grade of sand paper.

- Then sand the steel, aluminum or and the metal with a low-grit (400 or 600) coarse sand paper. ...

- Clean all surfaces with a cleaner that will not leave a residue.

- Wipe with a clean soft cloth.

- Saturate the silicone rubber surface with our Poly Prep, an adhesion promoter for polymers.

- Spray a solvent based Activator/Accelerator (AA) on either the silicone rubber or metal.

- Warm the silicone rubber surface with a hair dryer or heat gun. By touch, you want the silicone/poly just to below hot. By temperature, about 120 degrees F.

- Apply an SI Structural Adhesive to the opposite surface from where the AA was sprayed.

- Firmly press the two surfaces together for a minimum of fifteen seconds.

Will super glue work on silicone?

Super glue can be used to bond silicone rubber, but it is usually not recommended. The adhesive will interact with the material in an undesirable way. For instance, the silicone rubber’s surface may become glossy and the glue’s consistency may change when exposed to ultraviolet light.

How to remove silicone sealant, the easy way?

Remove Silicone Sealant. Spray WD-40 Multi-Use Product using the Smart Straw function onto a corner of the silicone sealant you want to remove. After a few moments of letting the solution set in, take advantage of the Silicone Sealant Removal Tool. Through its stainless steel blade, the three edges allow the removal of silicone with a push ...

How to apply silicone or caulk like a pro?

Instructions

- Choose the Right Caulk and Dispenser. Choose the right caulk and dispenser based on the needs of the project (see above). ...

- Remove Old Caulk and Clean the Surface. Removing the old caulk (as needed) and preparing the surfaces is very important for an effective caulk application and repair.

- Tape the Surfaces. ...

- Apply the Caulk. ...

How do you remove silicone from metal?

What You Will Need:

- Protective gloves

- Cutting knife

- Flexible Scraper or Spatula

- Clean Dry Cloth

- WD-40 Multi-Use Smart Straw

What kind of glue works on silicone?

Sil-Poxy will work with tin or platinum-cure silicones and provides a strong, flexible bond between silicone parts with high elongation. Sil-Poxy can be used repairing torn silicone rubber molds.

How do you fix silicone back together?

6:5011:08Best Glue for Silicone - 1-2-Fixed with Tech-Bond - YouTubeYouTubeStart of suggested clipEnd of suggested clipFirst saturate both the silicone rubber and the poly plastic piece with the poly. Prep. Let the polyMoreFirst saturate both the silicone rubber and the poly plastic piece with the poly. Prep. Let the poly prep dry.

How do I bond silicone to silicone?

Silicone rubber is one of the most challenging substrates to bond, and there are only a few adhesives that can make a strong bond. One option that has been successful in other silicone rubber applications is 3M™ Scotch-Weld™ Plastic & Rubber Instant Adhesive PR100 with 3M™ Scotch-Weld™ Instant Adhesive Primer AC79.

How do you fix a tear in a silicone mold?

2:457:12How To Repair a Torn Silicone Brush On Mold - YouTubeYouTubeStart of suggested clipEnd of suggested clipI am going to apply a small amount off the adhesive. Right into the tear carefully align this willMoreI am going to apply a small amount off the adhesive. Right into the tear carefully align this will help minimize any blemishes that could transfer onto our castings.

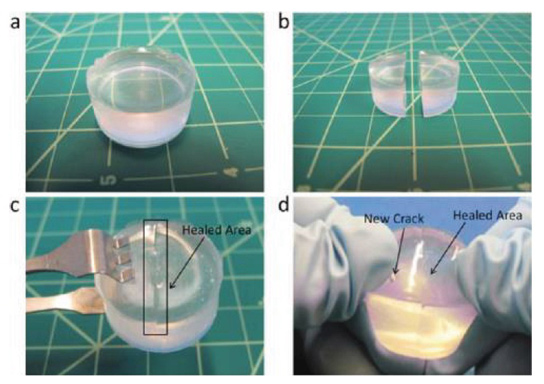

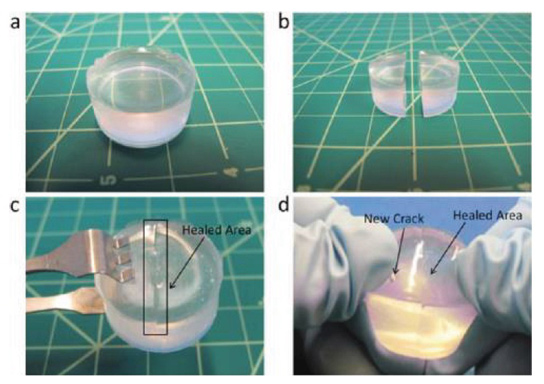

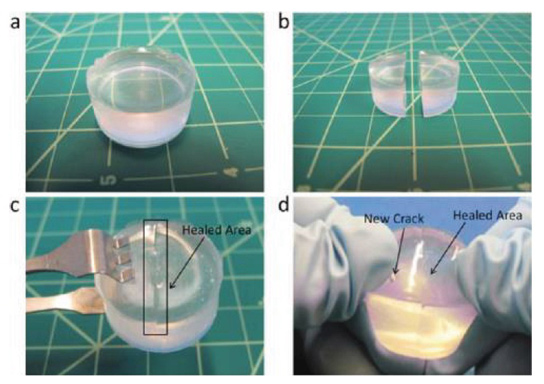

Can you fix broken silicone?

Although a repair may not be permanent, you can repair either a silicone or urethane rubber mold so that you can at least get a few more castings. You can then use that a casting to make a new mold.

Can you glue silicone back together?

Silicone-based adhesives tend to work well on silicone but if you are looking for a fast cure and to get away from isocyanate chemicals then options are limited. A polyolefin primer such as Permabond POP can be used to prime the surface of the silicone and then parts can be bonded with a cyanoacrylate.

Does silicone stick to dry silicone?

It is recommended that any old silicone is removed. While new, freshly applied silicone can be applied & will bond to old silicone – the bond isn't as strong as if it were applied to a clean surface.

Will Super Glue work on silicone?

Super glue can be used to bond silicone rubber, but it is usually not recommended. The adhesive will interact with the material in an undesirable way. For instance, the silicone rubber's surface may become glossy and the glue's consistency may change when exposed to ultraviolet light.

Does hot glue work on silicone?

Hot glue will not stick to very smooth surfaces, like metal, silicone, vinyl, wax, or greasy and wet surfaces.

Can you sew silicone?

Silicone is easy to stitch through First off, it is not hard to sew through the silicone. A needle pierces it and goes right through. It is a a little sticky material though, not like it sticks to your hands, but it doesn't slide through the machine.

Can you remould silicone?

Once cured, silicone cannot be simply re-melted (as vinyl can) but hardened leftovers and moulds which are no longer needed can be put to good use. In short, if these can be granulated they can be added as a filler to newly-mixed silicone.

How long does it take for silicone to bond?

The key to bonding any type of silicone is applying extra firm pressure for fifteen seconds, when the two surfaces are brought together. When this technique is used in conjunction with the Process, the silicone will be permanently, covalently bonded.

What is platinum cured silicone?

Two component platinum cured silicone rubber or platinum catalyzed silicone rubber or addition cure is extremely flexible, as well as strong. This flexibility and strength, combined with its library life, make it an ideal candidate for molecular bonding. More than applying a thick and clumsy sticky glue paste, a molecular bond is as it sounds. It forms a covalent bond between the two surfaces. With both the expensive cost of platinum and the precision required for accurate molds, bonding is really more of a must than a candidate. Paste epoxies that work by being sticky, simply do not provide adequate working time.#N#The molecular Process allows up to two minutes to perfectly align your platinum silicone, as long as you spray the Activator from the outside once bonded. The other bonding method calls for spraying the Activator on the opposite surface, but the bond with this method is almost immediate and does not provide ample working time. Platinum-cured silicone is often used in the food, beverage and medical sectors. Our molecular bonding system is food and dishwasher safe once dry.#N#Working with freshly minted platinum-cured silicone rubber is especially difficult. Chemical reactions are sill going on within freshly minted silicone rubber. Those reactions interfere with the chemical reactions critical to the Process . What is needed to offset the newness issue, is time. Once you firmly press the two pieces of freshly minted, platinum-cured silicone rubber together for the fifteen seconds necessitated by the Process, you need to give the result time.#N#Give the new/repaired piece a minimum of twenty-four hours to cure. Then you can put the piece back into use. More mature platinum-cured silicone rubber is easier to bond, but we still recommend the wait for all platinum-cured silicone rubbers. Platinum cured silicone is the most transparent silicone. Our surface insensitive adhesive and bonding tools dry clear. The sheer and tensile strength of platinum silicone, necessitate the need for a strong bond. Be sure to apply firm pressure and allow for the curing time.

What is methyl phenyl silicone?

Methyl phenyl silicone is a specialty silicone product with increased phenyl concentration. The addition of phenyl in replace of methyl, offers specific enhancements not present in standard silicone rubber. These improved characteristics include oxidation resistance, thermal stability, shear strength, visual clarity, radiation resistance, severe temperature resistance, severe pressure resistance, electric insulation and imperviousness to nearly all chemicals. Methyl phenyl silicones are the silicones used to produce permanent, non-stick coatings in pots and pans, that can withstand extremely high heat.#N#It is important to note all of these extraordinary properties when attempting to ‘ glue ‘ or bond methyl phenyl silicones. Our conductive bonding agent and subsequent bonding poly process can withstand a pressure, shear and tensile strength in the range of 2500 psi and below. We recommend avoiding bonding application where the temperature would rise above 240 degrees Fahrenheit. Our surface insensitive adhesive bonds are also impervious to nearly all chemicals. Most ‘super’ glues and epoxies are not able to withstand the specific extremes methyl phenyl silicones were designed for. Below is a picture of methyl phenyl silicone resin.

What is RTV silicone?

RTV Silicone Types. RTV silicone molds are distinguished by the type of curing process they employ. The most common of these are platinum cured silicones (addition cure), peroxide cured silicones (free radical cure) and tin cured silicones (condensation cure). It is possible to bond all silicone mold types.

What is platinum silicone used for?

Platinum-cured silicone is often used in the food, beverage and medical sectors.

Is silicone cured with peroxide?

There are a lot of positive aspects to peroxide-cured silicone rubber or peroxide catalyst silicones. Peroxide cured silicone rubber is easier to process, has a good shelf life and is usually less expensive. This type of silicone works by utilizing high temperatures to break down the peroxide and this in turn crosslinks the polymers. Bonding peroxide cured silicone is not that much different from bonding the platinum-cured. Extra firm pressure and a 24 hour cure time are necessary to achieve a strong bond.#N#With this type of silicone, it is also important to remember to wipe off any talc if used. If the talc is not completely wiped off, it will interfere with the bonding poly process. This was one of the first type of silicones used and is still in use today. It is imperative to make sure this silicone is fully cured before bonding, to ensure that it fully crosslinks and does not leave behind peroxide byproducts. This result would not only effect the strength of the material itself, but the strength of the bond.

Is platinum cured silicone easier to bond?

More mature platinum-cured silicone rubber is easier to bond, but we still recommend the wait for all platinum-cured silicone rubbers. Platinum cured silicone is the most transparent silicone. Our surface insensitive adhesive and bonding tools dry clear.