- Clean the area.

- Remove the defective pad and a short length of the connecting circuit. ...

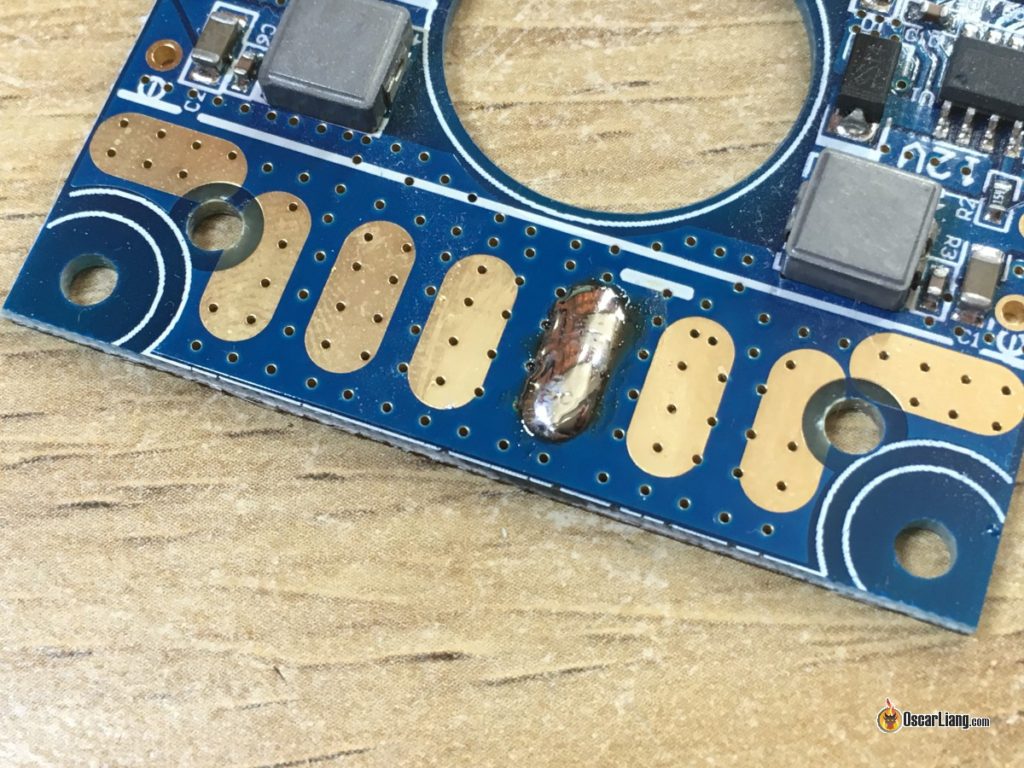

- Use knife and scrape off any epoxy residue, contamination or burned material from the board surface. ...

- Scrape off any solder mask or coating from the connecting circuit. ...

- Clean the area.

Full Answer

Can I repair a missing solder pad on a PCB?

Typically, when devices break or components are removed from PCBs, it can result in damaged and missing solder pads. The following instructional steps will help you repair a missing solder pad, so your PCB is ready for new components and further use.

What is a solder pad?

A solder pad is the part of a printed circuit board — or PCB — that supports the pins of components like transistors and chips. Typically, when devices break or components are removed from PCBs, it can result in damaged and missing solder pads.

How do I remove solder from the bottom of the pad?

First thing to do is clean up the area with a cotton-bud dipped in IPA (or acetone, probably if you don't have any IPA to hand). Do it very carefully, as it'll be easy to snag one of the other pads with solder sticking up and rip that off too, especially if it's been overheated.

How do I fix a damaged pad on my pad?

Removing the damaged pad: Use an X-Acto knife to carefully cut away the damaged pad. Cleaning the area around/under the damaged pad: After removing the pad, clean the area immediately around/under the pad.

What is solder pad?

How to remove solder mask from conductor?

How to cure a pad trace?

How to clean a pad?

Can you use open air to cure a lap joint?

How do you fix a broken soldering pad?

1:006:02How to Bypass Missing & Broken Solder Pads - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo we can just solder directly to that but getting to it will take a little bit of patience. AndMoreSo we can just solder directly to that but getting to it will take a little bit of patience. And finesse. So for a start use a sharp craft knife to scratch away the silk screen on top of the trace.

Can you fix a burnt solder pad?

You can't burn them away. If you damaged them during desoldering, then you would see them come off, and usually they stay connected to the traces on the board, so they are just sorta flopping around.

What do you do when your solder pad comes off?

I'd try first gluing down the torn-off pad in its original place. (Carefully unsolder it from the switch, without bending it, then glue it down using a tiny droplet of crazy glue.) Then, use solder to "tin" the scraped copper trace, then solder a tiny wire from the glued pad to the trace.

How do you fix the pad on a circuit board?

1:4710:17How To Repair Damaged /Missing PCB Pads - INVISIBLE Fix #solderingYouTubeStart of suggested clipEnd of suggested clipScreen i'll just put a little line across there that helps it to sort of be removed. Easy. Same withMoreScreen i'll just put a little line across there that helps it to sort of be removed. Easy. Same with this one. And then i can just get on what i do just get under the corner of the pad.

Can you solder over old solder?

Just heat the joint up with your torch, once the solder starts to melt use Channel locks to pull the fittings apart. Once the joint is apart, wipe as much old solder off as you can with a rag. Now you can start over. Clean, Flux, solder.

Can you reattach a solder pad?

Soldering the new pad/trace to the conductor: Use Kapton tape to place and hold the replacement pad. Use the appropriate solder alloy to make a lap joint. Clamping and curing: Clamp the new pad/trace in place and cure. Once cured, remove the clamp and clean the pad/trace with isopropyl alcohol.

How do you fix a burnt PCB pad?

How to Repair Damaged Printed Circuit Board PadsStep 1: Tidy Up the Damaged Track 1: ... Step 2: Tidy Up the Damaged Track 2: ... Step 3: Exposing the Track: ... Step 4: Sticking Copper Tape Over the Exposed Track: ... Step 5: Soldering the Copper Tape Joints: ... Step 6: Pierce to Make the Hole: ... Step 7: Solder in Your Component:More items...

How do you fix a lifted trace?

Step One: Locate the lifted trace, then identify the pads or joints on each end. Step Two: Clean the area with rubbing alcohol to remove any dirt or grease. Step Three: Cut any loose pieces of the trace from the board. Be extremely careful not to damage any other part of the board while doing this.

How do you solder a pad?

0:433:28How to Solder - Fill the pads with solder - YouTubeYouTubeStart of suggested clipEnd of suggested clipAfter you clean the soldering iron add a tiny bit of solder to the tip. So you can see where the hotMoreAfter you clean the soldering iron add a tiny bit of solder to the tip. So you can see where the hot part is touch the pad. And when the pad is hot enough add the solder to the pad.

How do you solder small pads?

0:145:40How To Solder to Small Pads - Specifically the R-XSR Receiver Un ...YouTubeStart of suggested clipEnd of suggested clipAnd it will heat up that pad at the exact moment. And allow that solder to stick in place. So I'mMoreAnd it will heat up that pad at the exact moment. And allow that solder to stick in place. So I'm gonna show you how I do that so I'm gonna hold it. There.

Why do solder pads lift?

Pad lifting on printed circuit boards during the assembly process is typically caused by a combination of a thermal and physical issue. The adhesion of the copper foil decreases as the surface heats up, so directly after soldering the copper adhesion can be low.

How do you fix a burnt PCB keyboard?

First, you need to get a smaller soldering iron. Second, you need to get some flux remover. Finally, when removing components with multiple pins it's generally best to cut the component into pieces so you can remove each pin smoothly and quickly - so you don't burn the board.

How do you fix a lifted trace?

Step One: Locate the lifted trace, then identify the pads or joints on each end. Step Two: Clean the area with rubbing alcohol to remove any dirt or grease. Step Three: Cut any loose pieces of the trace from the board. Be extremely careful not to damage any other part of the board while doing this.

How do you fix a broken PCB contact?

How to Repair Damaged Printed Circuit Board PadsStep 1: Tidy Up the Damaged Track 1: ... Step 2: Tidy Up the Damaged Track 2: ... Step 3: Exposing the Track: ... Step 4: Sticking Copper Tape Over the Exposed Track: ... Step 5: Soldering the Copper Tape Joints: ... Step 6: Pierce to Make the Hole: ... Step 7: Solder in Your Component:More items...

How do you fix a hole in solder?

0:343:1597CC - Plated-Through Hole Repair - YouTubeYouTubeStart of suggested clipEnd of suggested clipIf. You have inserted the eyelid into the termination side of the hole it may want to slip out aMoreIf. You have inserted the eyelid into the termination side of the hole it may want to slip out a piece of heat resistant tape will hold the eyelid in the hole. While you work with it.

How to repair solder pad?

The first one makes use of high-pressure curable adhesive and dry heat which sticks in the replacement pad. The other procedure uses two-part epoxy so that the replacement pad can be glued tightly to the laminate.

What are the important steps to repair missing solder pads?

Follow these steps to repair a missing solder pad so that your PCB gets ready for a new transistor or chip for further usage.

What is a solder pad?

So, what is a solder pad? It is a designated surface you get to see on a board of an integrated circuit die. They are the small surface of copper in PCBs that allows soldering the specific component to the board. A solder pad is like a piece of copper where the component pins are soldered and supported mechanically.

What is a thru hole solder pad?

Thru-hole solder pads, on the other hand, allow the pins of the part so that you can solder them from the opposite side from where you have inserted the part. These parts might be chips or transistors. In general, when the transistors or chips are removed or devices break down from the printed boards, it results in missing or damaged solder pads.

What chemical stripper to use on solder pad?

Because the chemical is liquid, it is hard to control. It attacks the coat and breaks it down. The most common chemical used is methlyene chloride. While they remove the solder pad quickly, they can deteriorate the material is exposed for a longer time.

What is surface mount solder?

You get to see two different types of solder pads, which are surface mount and thru-hole. The surface mount pads are for mounting devices on the surface. In short, soldering is done on the same surface where you have placed it.

Can you use a milling machine to remove solder?

So, will you use a milling machine to get rid of the solder pad? It might appear extreme, but it can be a precise and effective technique for removing the solder pad. Because sharp cutters will be in action, depth control is necessary. The milling system has to be fitted with a microscope to get clear visuals.

How to get solder resist off PCB?

Scrape a little of the solder resist off with a knife, sharp screwdriver or fine sandpaper. Ensure that the exposed track is clean and shiny. It is also a good idea to clean any residual burnt PCB material off, to allow the tape to stick well.

Can you repair a fault with solder?

It is possible to repair some faults using adhesive copper tape and solder.

Can copper tape be cut?

The Copper tape can be cut to size with scissors, craft knife etc. Once a repair has been made it is also possible to trim the excess tape. If this is done exercise caution, as the repair is more fragile than the original PCB track, and may become unstuck again.

Does copper tape melt?

Carefully solder the joint (s) where the repair has taken place. Most copper tape adhesive melts at soldering temperatures, so be quick and use as little heat as possible. When the tape cools the adhesive will usually remain sticky.

What is solder pad?

A solder pad is the part of a printed circuit board — or PCB — that supports the pins of components like transistors and chips. Typically, when devices break or components are removed from PCBs, it can result in damaged and missing solder pads.

How to remove solder mask from conductor?

Removing the solder mask: Using a toothpick, remove any existing solder mask from the conductor.

How to cure a pad trace?

Clamping and curing: Clamp the new pad/trace in place and cure. Once cured, remove the clamp and clean the pad/trace with isopropyl alcohol. Note: This is a good time to run a quick electrical continuity test. Once everything checks out, you may also want to envelop the edges of the new pad/trace with epoxy or solder mask to give the area increased mechanical strength.

How to clean a pad?

Cleaning the damaged pad: Thoroughly clean the damaged area with isopropyl alcohol, and follow up by drying the area with a lint-free cloth or compressed/canned air.

Can you use open air to cure a lap joint?

You can either use open air to cure it, or you can use an oven — but be sure to follow all manufacturer guidelines. Soldering the new pad/trace to the conductor: Use Kapton tape to place and hold the replacement pad. Use the appropriate solder alloy to make a lap joint.