How to Fix a Stripped Screw Thread with Inserts

- Remove the Bolt. The first thing you will need to do is remove the bolt. ...

- Clean the Remaining Threads. Once you have removed the bolt, use a clean rag, some compressed air, and penetrating oil to cleanse the remaining threads.

- Find the Right Drill Size. Examine the drill size that is listed on your coil-type thread insert's package, and make sure that you can drill the bolt-hole to this width.

- Screw the Thread Insert onto the Installation Tool. Next, take the thread insert and screw it entirely into the installation tool. ...

- Screw in the Thread Insert

How to tighten stripped bolt?

Watch These 3 Easy Tricks

- Method 2: Use Another Material to Aid in the Removal of the Stripped Allen Screw. ...

- Method 3: Make the Stripped Allen Screw Easier to Remove by Using a Special Substance. ...

- Method 4: Transform the Stripped Allen Screw into a Flat Head. ...

- Method 5: Modify the Indentation in the Stripped Allen Screw. ...

- Method 6: Enlist the Help of a Screw Extractor Kit. ...

How to restore bolt threads?

Whether your bolt is cross-threaded or has threads that are flat, there’s a fix. The first tool you could use is a thread file, or thread restoring file. This tool actually has 8 different sizes of thread pitch on it, everything from 11 up to 24. Taking the flat threads and running them over the file will get rid of them.

How can you fix a stripped screw thread in block?

How to fix a stripped bolt hole in aluminum

- Try a longer bolt. Over time bolt s and threads sometimes lose their strength. ...

- Use a thicker bolt. ...

- Insert a helicoil. ...

- Try an aluminum braising rod. ...

- Use JB Weld. ...

- Try strands of copper wire. ...

- Use aluminum foil. ...

- Pour some Loctite epoxy. ...

- Use a welder. ...

- In conclusion. ...

How to repair stripped out drain plug threads?

The Process

- Drain just about every drop of oil from the car. ...

- Jack the car up in the front, so it tilts away from where the oil pan drain is located. ...

- Clean the drain plug opening thoroughly with brake cleaner or acetone and let the car sit in that position until the oil pan drain opening is perfectly dry

- Mix the JB Weld. ...

What happens if you use a fine thread bolt in a coarse thread hole?

What happens if you misalign bolts?

What is a thread chaser?

Can you drill and tap a hole?

Can you assemble a bolt with stripped threads?

Can you use OEM bolts?

See more

About this website

Can you fix stripped threads on a bolt?

Damaged threads on a screw or bolt can often be fixed by running a die over it, and if a thread's damage is minimal, it may be possible to reform the threads by running a nut up and down them, though that runs the risk of the nut fusing to the thread (galling).

How do you Rethread stripped bolt holes?

1:072:46How to Fix Stripped Bolt Hole Threads on Your Car - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo basically we get our long extension stick it in the hall with a threading tool. And start to turnMoreSo basically we get our long extension stick it in the hall with a threading tool. And start to turn the ratchet. To eat the threads. In. And when it starts to get snug.

Can you Rethread a stripped thread?

Restore stripped threads quickly with a rethreading kit A rethreading kit is an important part of any automotive toolbox. Use it to restore stripped threads on old, rusty nuts and bolts when you don't have time to search the stores for a replacement.

How do you fix a stripped bolt hole without drilling?

0:442:11Easily repair a cross threaded hole without a tap! - YouTubeYouTubeStart of suggested clipEnd of suggested clipSlide to the bolt will make our act as a cutter when it gives it a relief for the material to getMoreSlide to the bolt will make our act as a cutter when it gives it a relief for the material to get into the slide. Once you run that through the thread your bolts for reading with its.

Can you use Loctite on stripped threads?

Loctite® Form-A-Thread® It restores worn, stripped or damaged threads and eliminates future corrosion, galling, seizing, and rust, and allows up to 128 ft. lbs. of torque between -65°F to 300°F. It permanently repairs stripped threads and fasteners in five minutes (up to SAE Grade 5 English and 8.8 metric).

How do you fix a stripped bolt hole in metal?

0:039:51FIX stripped bolt hole threads the POOR MANS WAY - YouTubeYouTubeStart of suggested clipEnd of suggested clipLet's find it out keep watching. So here we got a piece of cast aluminum that I have intentionallyMoreLet's find it out keep watching. So here we got a piece of cast aluminum that I have intentionally stripped out some threads.

What can I use for stripped threads?

Some common methods you can use to fix stripped threads are:Threaded insert kit. A threaded insert kit allows you to enlarge the stripped hole with a specialized drill bit, allowing you to put in a threaded insert. ... Epoxy. You can use epoxy to fill the damaged hole. ... Drill a larger hole and tap it.

Can you Rethread a hole of the same size?

This is done in a similar manner as a tap, but the shaft of the part threads through the die as it cuts the threads. In most cases, parts like these can be re-threaded, but they must be done with the same size threads, you can't cut the next size smaller threads.

Can you use a tap to repair threads?

6:1511:17How To USE A TAP AND DIE To FIX DAMAGED THREADS ... - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo we just went ahead and fixed those threads. Not too shabby. So that's how you use a tap to fix aMoreSo we just went ahead and fixed those threads. Not too shabby. So that's how you use a tap to fix a stud or threads of a bolt. Let me show you how to use a tap. So a tap is going to fix a hole.

Loctite Stripped Thread Repair Tip | Fix My Hog | Fix My Hog

How-to video on stripped thread repair. Form A Thread from Loctite makes it an easy fix. Loctite has a great product for motorcycle repair.

How to repair a hole in a bolt?

Choose a thread tap that matches the original bolt's thread pattern. Dip the tap in a light oil; motor oil works great for this. Work the tap into the hole until hand-tight. Place a wrench on the square end of the thread tap and run the tap into the damaged hole a couple of times.

How to tighten a bolt?

Press the bolt into the hole and twist clockwise. The bolt should turn easily. Once hand-tight, place the proper sized wrench or socket on the bolt's head and tighten as needed. When applicable, use a torque wrench and turn the bolt clockwise until it reaches the manufacturers recommended torque limit.

How to tell if a bolt hole is damaged?

Symptoms of a badly damaged bolt-hole range from a bolt that loses grip when applying moderate torque, to one that spins freely. The repair methods also vary greatly. When used appropriately, a simple chemical thread-filler works remarkably well. The popular thread-insert repair method returns a hole to its original size. Sometimes using a longer nut and bolt solves the thru-hole issues that cause inserts problems, such as insert pass through.

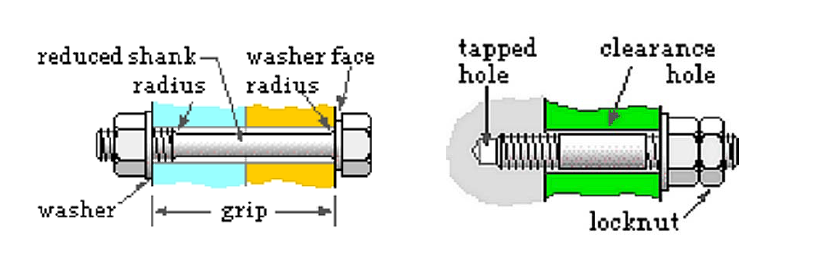

What is thread repair insert?

A thread-repair insert acts as a bushing between an over-sized hole and a properly sized bolt. A popular insert has an expanding coil design; others look like a standard bushing. A basic thread repair kit contains a thread tap, insert and an installation tool. Thread-insert installation requires a properly sized drill bit.

How to stop a bolt from vibrating?

Use thread-locking material on bolts susceptible to vibration. After the thread-locking material dries, a semi-permanent bond forms, preventing the bolt from vibrating loose. When working with a blind hole application, apply the thread-locking material to the bolt's male threads. Excess thread-locker in a blind hole can stop the end of the bolt from bottoming out. In thru-hole applications, cover the hole's female threads before inserting the bolt.

How to install a thread locker?

Place thread locker, if manufacturer recommended, on the appropriate surface. Screw the insert into the hole, stopping when the insert bottoms out. Remove the installation tool. Complete the repair and install a new bolt.

What does tap do in a hole?

A tap creates female threads in a hole.

How to remove a bolt that has been stripped?

If the hole is completely stripped and you cannot get enough grip to remove the bolt, you will need to drill into the center of the bolt and have a bolt extractor on hand to remove it .

How to deal with stripped bolt holes?

This can end up being an expensive headache if it happens. Best practice here is to avoid using a cutting tap which will remove metal. In these very sensitive environments, you want to consider using a forming or a chasing tap instead. Rather than cutting away metal, these taps will simply reform it.

How to drill a hole in a coil type thread?

A drill block will help you ensure that the hole you are drilling remains straight. You need to use cutting oil to cover the tap, and occasionally back it up to clear out fillings which can become impacted if this is not done. (Remember that if you are working in a sensitive part of the car where metal shavings can cause major damage that you want to use a forming tap instead.)

How long does it take to replace a stripped bolt hole?

Like with many aspects of mechanics, the more you do it the better you will get. Many seasoned mechanics can completely replace female threads in less than 10 minutes.

How to clean bolts after removal?

Once you have removed the bolt, use a clean rag, some compressed air, and penetrating oil to cleanse the remaining threads . If you have a Shop-Vac, it can be very helpful for this process.

Can a thread chaser remove rust?

This is the easier of the two options to fix stripped bolt holes, given that the thread chaser will carve away rust and help redefine the threads, but it will not remove or reform the metal. This is very useful in areas around the engine, where manifold intake could be a problem with metal fillings. In reality, this is more like cleaning out the ...

Can you make a stripped bolt hole work?

Many people are tempted to try and “make it work” when it comes to dirty or damaged female threads; however, this is not wise. It is better to deal with a stripped bolt hole as soon as you realize it's a problem. Dealing with a stripped bolt hole can be a bit irritating, but it's a lot less irritating than dealing with the damage that one can cause.

How to repair stripped threads in aluminum?

If there are heat-sensitive objects nearby you may not be able to use this option. If you’re fine with heating up the area you can fill then retap the hole . This will help you repair stripped threads in aluminum.

Why do bolts lose their strength?

Over time bolt s and threads sometimes lose their strength. Due to friction or corrosion, the threads can deteriorate. Having these weak threads can prevent you from being able to tighten down a bolt. The first option is looking at the bolt hole. If you have some extra distance that the bolt doesn’t cover you may be able to use a longer bolt. If there are some decent threads that your longer bolt can reach you may be able to tighten it down.

How to make a bolt hole snug?

Just like the the copper wire above aluminum foil can be used in the same fashion. Tear a few pieces of aluminum foil off and fold them over. Place them down in the bolt hole and after a few twists of the bolt it should start to become snug.

What is JB weld?

JB Weld is usually a 2 step epoxy that can be used to join things together permanently. Alternatively, you can use the stripped thread repair epoxy to fill the hole and tap it afterward. If you are not worried about being able to remove the bolt later on you can put the JB Weld on the bolt and tighten it down.

What is a helicoil thread?

If neither of the options above are doing it for you can use a Helicoil. A Helicoil is a coil wired thread insert. The coil replaces the original threads. Essentially you drill out the hole with the correct bit size. You can then tap the hole and insert the coil. After the coil is inserted you then bust off the tang.

Can you drill a hole in a bolt?

If most of the threads have been a victim of damage you may be able to increase the size of the hole. As long as there is enough room on the outside you may be able to drill out a larger hole. This will allow you to rethread the hole and give you the ability to use a larger bolt.

Can you use a longer bolt?

The first option is looking at the bolt hole. If you have some extra distance that the bolt doesn’t cover you may be able to use a longer bolt. If there are some decent threads that your longer bolt can reach you may be able to tighten it down.

How to use stripped threads on plastic?

Assuming the stripped threads are the female side (i.e. the threaded hole), then the best thing would be to tap the hole to the next larger side and then use the corresponding larger bolt. E.G. if your hole is M6, then tap it to M8 and use an M8 bolt. Taps are easy to do in most plastics and not terribly expensive. I recommend against using an electric drill tap — just do it by hand.

What to use to loosen a bolt?

If it is a medium strength or 'blue' thread locker (ex. Loctite 243) , simply applying the breakaway torque with a torque wrench or pipe would loosen the bolt. (Generally used for medium sized bolts )

What is thread chaser?

Thread chasers are used when a threaded hole is essentially intact but the threads are slightly damaged and can be cleaned up by using the thread chaser, which is essentially a tap that can be screwed into the hole to cut away the damaged or burred threads. Inserts on the other hand are used when the threaded hole is damaged beyond repair by a thread chaser. In those cases the hole is drilled out to a larger size, per the specifications with the inserts being used, and then tapped to allow the insert to be installed. The insert has an external configuration that locks into the enlarged drilled

How to repair a bolt hole?

There are several ways depending on the parent material and what is the function and load on the bolt….sometimes it’s best if convient to just drill out to next size and retap….if the original size is demanded their are a few thread insert repairs available like heli coil or thread insert…it’s possible to weld up hole with new material and then drill and tap to the desired size….there are also a few compounds that can be used to fill hole and and bolt inserted and the thread will be restored …liquid metal or JB weld I have used in non critical repairs

What to use to tighten thread locker?

If it is a low strength or wicking type thread locker (ex. Loctite 222), simply applying some extra torque using a spanner or screwdriver would do the job. (Generally used for small size screws and bolts)

What does it mean when a bolt is over tightened?

Over tightening - too much torque applied to the bolt exceeding the tensile strength rating of the bolt This will usually snap off the bolt head, as bolts are rated against stretch, not twist. But if the bolt is threaded onto a different material ( brass v steel) the softer metal will strip first.

What happens when you cross thread?

Cross threading - marred, or otherwise damaged threads will not marry up properly and will accumulate damage until the threads are destroyed

What happens when you strip a bolt?

When you strip one out or break a bolt inside the hole, the threads are damaged. In some cases you can re-tap the threads with good results, but if the fastener is under high load or critical, then you will likely have to go to the next size up. These holes use taps, which cut threads into the metal.

How to get chips out of a thread?

Once the threads are cut, you need to clean out the hole. Spray it with compressed air, brake cleaner or lubricant to get all the chips out.

What is a taper in a blind hole?

The taper is there to guide the tap in the hole and to slowly cut the threads in fresh material. While this is great for through-holes, where the backside of the hole is open, these only get part of the job done when you are working with a blind hole, where the hole is closed. For that, you need a bottoming tap.

What is a taper tap?

The taper tap is the most common tap design. This is the style used for creating new threaded holes. The first 8 to 10 cutting flutes of the tap are not full, they gradually build up to the full thread size. The taper is there to guide the tap in the hole and to slowly cut the threads in fresh material.

Why do taps have tapered flutes?

The tapered flutes help ensure that the tap is centered and vertical. We ran the tap all the way through the part, so that the bottom threads were touched by the full flutes of the tap. The chips in the relief grooves of the tap are called swarf, they should be cleaned off before putting the tap away.

How many flutes does a plug tap have?

The plug tap is in the middle, it uses 3-5 gradual flutes. Each tap style serves a different purpose. From the left- taper, plug, and bottoming. If you are repairing damaged threads, either of these taps will usually work, unless it is a blind hole, in which you need to use a bottoming tap.

How do threaded parts work?

They are twisted by hand, and slowly work their way into hole being tapped. Threaded parts such as bolts, shafts, and other similar parts use dies to cut the threads. This is done in a similar manner as a tap, but the shaft of the part threads through the die as it cuts the threads.

What is thread repair insert?

Thread-repair inserts come in a variety of materials and in a myriad of designs from domestic and overseas manufacturers. Timed thread body inserts, wire coil inserts and keyed inserted make up the three major families of thread inserts you’ll likely encounter.

How to repair M10x1.25 thread?

For an M10x1.25 thread repair with a Keensert, a 12.5mm drill would be used for the M14x1.5 tap. The M14x1.5 tap would have a major diameter up to 14.4mm (an M10 repair with an S.T.I. tap would only have a 11.787mm major diameter). That’s a much bigger hole which can be beneficial in some application where severe corrosion is prevalent in the original threads. The Keensert would then be threaded into the drilled, tapped and cleaned hole with the Keensert installation tool. Thread locking compounds can be used due to its solid body design. Once set in position, the installation tool is then used to drive in the four key stakes into position. This provides the ultimate mechanical locking of the insert in place. Hence, this design sports exceptional resistance to vibration. Now the downside. The massive outside diameter of the insert makes it unviable in applications where the material around the original threaded hole is limited, such as any “thin-wall” castings. Second, the cost for a standard-steel Keensert is about 4.5 times that of a HeliCoil and more than double the cost of a TIME-SERT. If you want a stainless-steel Keensert, the cost goes through the roof being about 25 times the cost of a HeliCoil.

What size drill do I use for a M10x1.25?

First, you would drill the hole with a 10.25mm drill (a standard M10x1.25 thread would use a much smaller 8.75mm drill). Then you would use an M10x1.25-S.T.I. tap. This S.T.I. version of the tap will have a major diameter of up to 11.787mm, whereas a standard M10x1.25 tap is about 1.5mm less in diameter.

How hard is it to drill a stripped hole?

How easy or how hard usually depends on the access to the stripped hole. If you can take off the entire header and get enough access to fit a cordless drill in the area to drill out the hole before tapping, it pretty easy. I;'m guessing it would probably be an M8x1.25 thread. Compare the size and thread on one of the good bolts to a know M8x1.25 bolt to confirm.

Can you have a thread failure in the same hole again?

Done right, you’ll never have a thread failure in the same hole again.

Is stripper thread more common than ever?

As a result, it’s no surprise that strippers are more common than ever before. Since most of the threads on today’s vehicles are made of materials with just one-third to one-half the hardness of grey cast iron, it’s no wonder that more threaded holes experience thread damage than ever before.

Can Keensert be threaded?

That’s a much bigger hole which can be beneficial in some application where severe corrosion is prevalent in the original threads. The Keensert would then be threaded into the drilled, tapped and cleaned hole with the Keensert installation tool. Thread locking compounds can be used due to its solid body design.

What happens if you use a fine thread bolt in a coarse thread hole?

Mismatched Bolts and Holes: Using a fine-thread bolt in a coarse-thread hole or a metric bolt in an SAE hole can result in interference and stripped threads as the pieces try to conform to each other.

What happens if you misalign bolts?

Misalignment: If parts are misaligned during assembly, the bolts may not go straight into the holes, resulting in cross-threading or deformed threads.

What is a thread chaser?

Thread Chaser: A thread chaser rolls and reforms the deformed threads. If possible, chase the threads starting from the undamaged section. This can be done for spark plugs or caliper bolts, for example.

Can you drill and tap a hole?

Drill and Tap: You can drill and tap the hole larger to accommodate a larger fastener. Going up one or two sizes is allowable in many circumstances, but be sure to use the correct drill bit to retain the strength of the attachment. Keep in mind that tapped threads don’t retain their strength as well as chased threads because a tap may remove too much metal. Nevertheless, a tap and die set is a necessary addition to anyone’s toolbox.

Can you assemble a bolt with stripped threads?

It’s only a matter of time before you run across a stripped bolt-hole or stripped threads in your DIY repair project. And if the threads are stripped, you can’t assemble the parts and achieve the correct torque. Here’s why this issue occurs and how to fix stripped threads so you can reassemble the components correctly.

Can you use OEM bolts?

Epoxy: For low-torque applications, high-strength epoxy can allow you to use the OEM bolt size. After cleaning and applying a release agent to the bolt, put epoxy into the damaged hole and on the bolt. Threading in the bolt will force the epoxy into the existing threads. Once the epoxy cures, install new bolts as needed.