How to Fix a Stripped Screw Thread with Inserts

- Remove the Bolt. The first thing you will need to do is remove the bolt. ...

- Clean the Remaining Threads. Once you have removed the bolt, use a clean rag, some compressed air, and penetrating oil to cleanse the remaining threads.

- Find the Right Drill Size. Examine the drill size that is listed on your coil-type thread insert's package, and make sure that you can drill the bolt-hole to this width.

- Screw the Thread Insert onto the Installation Tool. Next, take the thread insert and screw it entirely into the installation tool. ...

- Screw in the Thread Insert

How do I repair a stripped bolt?

how do I fix a stripped bolt in aluminum heads?

- rsliska. I was tightening my valve cover bolts on my aluminum heads and stripped the bolt hole. ...

- Ben Smith. Heli-Coil makes an insert that fixes stripped threads, you buy a kit that has a larger size drill bit, a special tap and an installation tool that installs ...

- rsliska. ...

- Bob Cowan. ...

- limey

- wibby. ...

- Ben Smith

- wibby. ...

- Scott L. ...

- dv/dt. ...

How to save a stripped bolt?

Tool List

- PB Blaster or other penetrating fluid

- Locking pliers

- Normal socket set

- Extraction socket set

- Blowtorch

- Bolt extractor kit

- Dremel or similar cutting tool

- Flathead screwdriver

- Drill and drill bits

How to fix stripped bolt hole?

What is the best wood filler for screw holes?

- Abatron WoodEpox Replacement Compound.

- Minwax 12-ounce High-Performance Wood Filler.

- Elmer’s Carpenter’s Wood Filler Tube.

- FamoWood Latex Wood Filler.

- J-B Weld Wood Epoxy Adhesive.

- 3M Bondo Home Solutions Wood Filler.

How to rethread a stripped bolt hole?

Method #3) Install a Helicoil Insert

- Prepare the Old Hole. The first step in this process is to prepare the old hole. ...

- Find the Right Size Helicoil Insert. One of the most essential parts to having success installing a Helicoil insert is determining the right size.

- Create New Threads with a Tap Set. ...

- Install the Helicoil Insert. ...

- Remove the Tang. ...

How do you fix a stripped metal hole in a bolt?

0:062:44Fixing a Stripped Bolt Hole in Metal - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo there's a couple ways to do this you can use something called a helicoidal which i've alwaysMoreSo there's a couple ways to do this you can use something called a helicoidal which i've always thought was a little like hokey.

How do you Rethread head bolts?

7:338:47How to Repair Stripped Cylinder Head Bolts on a Toyota 2.4 L EngineYouTubeStart of suggested clipEnd of suggested clipIt in should get a little tight as you get close to it at the bottom. So once it once you get toMoreIt in should get a little tight as you get close to it at the bottom. So once it once you get to your mark. Then you can go ahead spin your tool back out and the insert will stay inside the ice.

Can you use Loctite on stripped threads?

Loctite® Form-A-Thread® It restores worn, stripped or damaged threads and eliminates future corrosion, galling, seizing, and rust, and allows up to 128 ft. lbs. of torque between -65°F to 300°F. It permanently repairs stripped threads and fasteners in five minutes (up to SAE Grade 5 English and 8.8 metric).

Should head bolts be Retorqued?

In most cases you don't need to retorque head bolts or studs. If the bolts or studs aren't tight you will lose compression or get coolant in your cylinders. You can use bolts or studs based on application, but studs tend to give more consistent torque values. Never reuse Torque-To-Yield (TTY) bolts.

What happens if you over torque a head?

2:1012:42What happens when you over torque a bolt? - YouTubeYouTubeStart of suggested clipEnd of suggested clipOr the bolt will permanently deform.MoreOr the bolt will permanently deform.

Why do cylinder head bolts need to be tightened in several phases?

Your one-use-only head bolts are meant to be tightened to a different criterion - specifically, beyond their plastic-deformation point, the point at which they stretch and don't return to their original length when loosened. These head bolts need to be tightened in a very different fashion.

Can you change head bolts one at a time?

The question is, can I replace a bad or lost head bolt with a bolt that looks exactly the same as the head bolts known to be correct. The answer is yes, but only if the replacement head bolt meets the grade of the correct head bolts. For example, using a Grade 3 or Grade 5 bolt as a head bolt will be a bad idea.

What is the ARP cleaning tap for 7/16 x 14 bolts?

But don’t use a normal tap. Normal thread taps remove block material that will only increase the chances of pulling threads in other holes. ARP makes a thread cleaning tap that is designed to sweep the threads but not remove metal. For your 7/16 x 14 head bolts, the cleaning tap is PN 911-0004.

How thick is a cylinder block?

The simplest is an aluminum or steel block about two inches thick and roughly six or seven inches long. The block must be perfectly flat on the cylinder block face. Next, you could use transfer punches and a cylinder head as a guide to drill three holes.

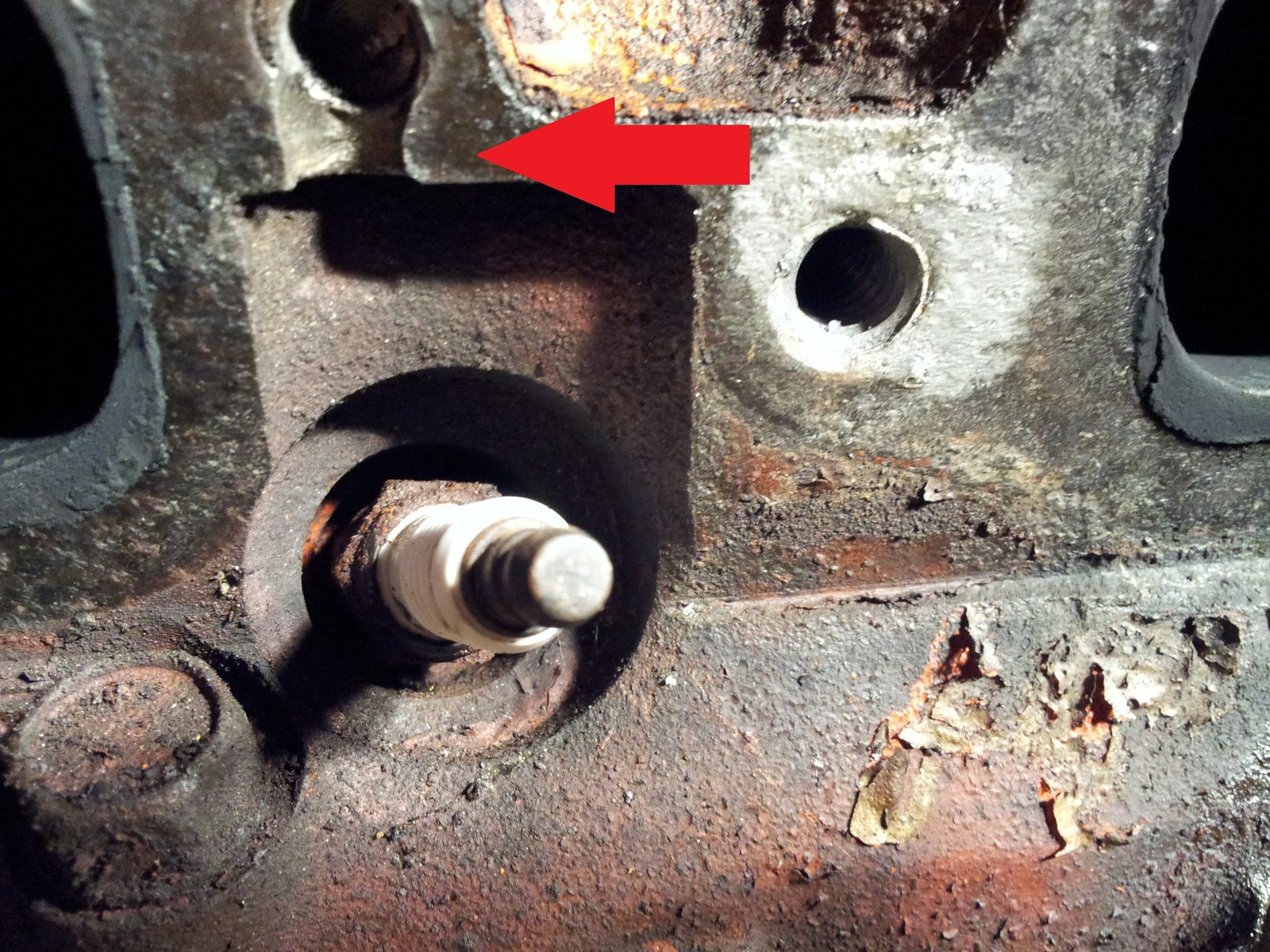

Do you need a depth limiter for a stripped head bolt hole?

You don’t need a depth limiter for enlarging the stripped hole since all production small-block Chevy head bolt holes open into the water jacket. If you were doing this on an engine with blind head bolt holes, you would definitely want to indicate drill depth with a mark on the drill bit.

How to repair a hole in a bolt?

Choose a thread tap that matches the original bolt's thread pattern. Dip the tap in a light oil; motor oil works great for this. Work the tap into the hole until hand-tight. Place a wrench on the square end of the thread tap and run the tap into the damaged hole a couple of times.

How to tell if a bolt hole is damaged?

Symptoms of a badly damaged bolt-hole range from a bolt that loses grip when applying moderate torque, to one that spins freely. The repair methods also vary greatly. When used appropriately, a simple chemical thread-filler works remarkably well. The popular thread-insert repair method returns a hole to its original size. Sometimes using a longer nut and bolt solves the thru-hole issues that cause inserts problems, such as insert pass through.

What is thread repair insert?

A thread-repair insert acts as a bushing between an over-sized hole and a properly sized bolt. A popular insert has an expanding coil design; others look like a standard bushing. A basic thread repair kit contains a thread tap, insert and an installation tool. Thread-insert installation requires a properly sized drill bit.

Why does a blind hole stop before it passes through a block?

A blind hole stops before it passes through the block. Debris packed into the bottom of a blind hole can make a bolt bottom-out prematurely. This common error initially leads to loose fitting parts and leaking gaskets. Trying to tighten a bolt in a debris packed blind hole often leads to stripped threads. Because a thru-hole, sometimes called a clearance hole, passes completely through the block, debris cannot build up.

How to stop a bolt from vibrating?

Use thread-locking material on bolts susceptible to vibration. After the thread-locking material dries, a semi-permanent bond forms, preventing the bolt from vibrating loose. When working with a blind hole application, apply the thread-locking material to the bolt's male threads. Excess thread-locker in a blind hole can stop the end of the bolt from bottoming out. In thru-hole applications, cover the hole's female threads before inserting the bolt.

How to tighten a bolt?

Press the bolt into the hole and twist clockwise. The bolt should turn easily. Once hand-tight, place the proper sized wrench or socket on the bolt's head and tighten as needed. When applicable, use a torque wrench and turn the bolt clockwise until it reaches the manufacturers recommended torque limit.

How to install a thread locker?

Place thread locker, if manufacturer recommended, on the appropriate surface. Screw the insert into the hole, stopping when the insert bottoms out. Remove the installation tool. Complete the repair and install a new bolt.

How to repair stripped threads in aluminum?

If there are heat-sensitive objects nearby you may not be able to use this option. If you’re fine with heating up the area you can fill then retap the hole . This will help you repair stripped threads in aluminum.

How to make a bolt hole snug?

Just like the the copper wire above aluminum foil can be used in the same fashion. Tear a few pieces of aluminum foil off and fold them over. Place them down in the bolt hole and after a few twists of the bolt it should start to become snug.

What is JB weld?

JB Weld is usually a 2 step epoxy that can be used to join things together permanently. Alternatively, you can use the stripped thread repair epoxy to fill the hole and tap it afterward. If you are not worried about being able to remove the bolt later on you can put the JB Weld on the bolt and tighten it down.

How to make a solid surface with aluminum?

Try an aluminum braising rod. If you are able to you can heat up the area and use an aluminum braising rod. The process is almost like soldering where the aluminum melts then cools to create a solid surface. You have to heat up the surface to a temperature where the aluminum rods will melt.

What is a helicoil thread?

If neither of the options above are doing it for you can use a Helicoil. A Helicoil is a coil wired thread insert. The coil replaces the original threads. Essentially you drill out the hole with the correct bit size. You can then tap the hole and insert the coil. After the coil is inserted you then bust off the tang.

Why do bolts lose their strength?

Over time bolt s and threads sometimes lose their strength. Due to friction or corrosion, the threads can deteriorate. Having these weak threads can prevent you from being able to tighten down a bolt. The first option is looking at the bolt hole. If you have some extra distance that the bolt doesn’t cover you may be able to use a longer bolt. If there are some decent threads that your longer bolt can reach you may be able to tighten it down.

Can you drill a hole in a bolt?

If most of the threads have been a victim of damage you may be able to increase the size of the hole. As long as there is enough room on the outside you may be able to drill out a larger hole. This will allow you to rethread the hole and give you the ability to use a larger bolt.