How to Fix a Stripped Screw Thread with Inserts

- Remove the Bolt. The first thing you will need to do is remove the bolt. ...

- Clean the Remaining Threads. Once you have removed the bolt, use a clean rag, some compressed air, and penetrating oil to cleanse the remaining threads.

- Find the Right Drill Size. ...

- Screw the Thread Insert onto the Installation Tool. ...

- Screw in the Thread Insert

How to repair stripped bolt hole threads?

How to Repair Stripped Bolt Hole Threads 1 Partially Stripped Threads. Partially stripped bolt-hole threads often vibrate loose or let go before applying maximum torque. ... 2 Badly Damaged Threads. ... 3 Thread-Repair Insert. ... 4 Install Bolts Correctly. ... 5 Thru-Hole Repairs Using a Nut. ... 6 Questions & Answers. ... 7 Comments

How do you repair damaged threads on a car?

All you need to repair damaged threads is some patience and a tap and die set. Threaded holes can be found in all areas of your vehicle, from the engine to the chassis. These holes are tapped with the correct size of threads for the job at hand. When you strip one out or break a bolt inside the hole, the threads are damaged.

What happens if you tighten a bolt in a thru hole?

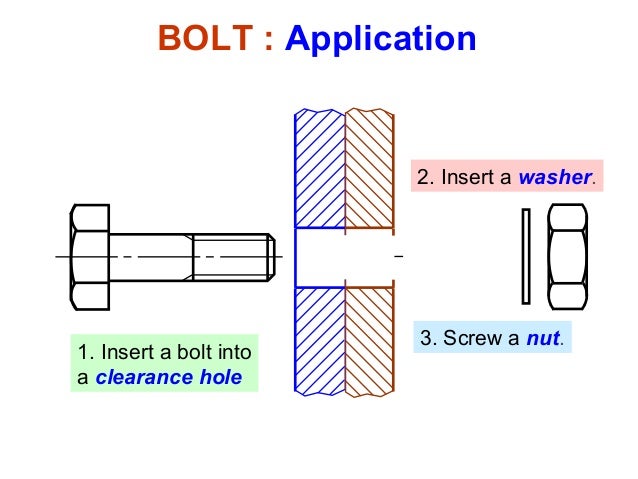

Trying to tighten a bolt in a debris packed blind hole often leads to stripped threads. Because a thru-hole, sometimes called a clearance hole, passes completely through the block, debris cannot build up. A tap creates female threads in a hole. Partially stripped bolt-hole threads often vibrate loose or let go before applying maximum torque.

What happens if you break a bolt with a tap?

These holes are tapped with the correct size of threads for the job at hand. When you strip one out or break a bolt inside the hole, the threads are damaged. In some cases you can re-tap the threads with good results, but if the fastener is under high load or critical, then you will likely have to go to the next size up.

Can you fix stripped threads on a bolt?

Damaged threads on a screw or bolt can often be fixed by running a die over it, and if a thread's damage is minimal, it may be possible to reform the threads by running a nut up and down them, though that runs the risk of the nut fusing to the thread (galling).

Can you rethread a bolt hole?

Use a rethreading tap to restore threads on nuts or threaded engine component holes. Don't try to rethread the entire bolt, hole or nut in one operation. Insert the rethreading tap or die and rotate a few turns, then back it off a full turn. That will dislodge the debris from the teeth.

How do you fix a stripped metal hole in a bolt?

0:062:44Fixing a Stripped Bolt Hole in Metal - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo there's a couple ways to do this you can use something called a helicoidal which i've alwaysMoreSo there's a couple ways to do this you can use something called a helicoidal which i've always thought was a little like hokey.

How do you fix a bolt that won't thread?

0:483:08How to Repair Damaged Threads on a Bolt - Kevin Caron - YouTubeYouTubeStart of suggested clipEnd of suggested clipYou can't get down in there and be able to have enough room to spin that thing around down in a holeMoreYou can't get down in there and be able to have enough room to spin that thing around down in a hole someplace trying to fix like a stud on a motor. There's another way these are called thread files.

Can you use Loctite on stripped threads?

Loctite® Form-A-Thread® It restores worn, stripped or damaged threads and eliminates future corrosion, galling, seizing, and rust, and allows up to 128 ft. lbs. of torque between -65°F to 300°F. It permanently repairs stripped threads and fasteners in five minutes (up to SAE Grade 5 English and 8.8 metric).

How do you Rethread screw holes in metal?

How Do You Fill Stripped Screw Holes in Metal?Use a specialized bit to enlarge and thread the hole, then insert a new screw.Drive a larger-diameter, self-tapping screw into the hole.Fill the hole with metal epoxy, then drive the original screw back into the hole.More items...

How do you fix a screw that won't tighten metal?

0:177:5413 Annoying Loose Screws Around the House & How to Fix ThemYouTubeStart of suggested clipEnd of suggested clipAnd you can also apply a product like the thread stopper tape wrap it around a couple of times onMoreAnd you can also apply a product like the thread stopper tape wrap it around a couple of times on the threads. And that will hold it in there a lot easier and a lot longer.

Can you Rethread a hole of the same size?

This is done in a similar manner as a tap, but the shaft of the part threads through the die as it cuts the threads. In most cases, parts like these can be re-threaded, but they must be done with the same size threads, you can't cut the next size smaller threads.

How do you Rethread a rusted bolt hole?

0:031:04How to Clean Rusted Nut Threads - CURT - YouTubeYouTubeStart of suggested clipEnd of suggested clipWe suggest using a thread tap. Choose the correct tap by using the hardware specification chartMoreWe suggest using a thread tap. Choose the correct tap by using the hardware specification chart located on the supplied instruction sheet. Use caution when threading the tap into the weld nut.

How do you fix a stripped screw hole?

0:446:22How to Fix Stripped Screw Holes - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd get some toothpicks for this hole right here three ought to do it just place them in the hole.MoreAnd get some toothpicks for this hole right here three ought to do it just place them in the hole. Like that break off the excess.

How do you Rethread a spark plug hole?

0:322:45How to Fix Stripped Spark Plug Hole in Your Car - YouTubeYouTubeStart of suggested clipEnd of suggested clipStart turning it to start. It. Then very slowly turn it to cut the threads. You don't want to breakMoreStart turning it to start. It. Then very slowly turn it to cut the threads. You don't want to break anything you want to do it nice and smooth. And once it bottoms out then you are thriving.

Why does my thread get damaged?

Typically, thread damage on a a male thread (a screw or a bolt for instance) is caused when incorrect bolt torque is used, when thread fretting occurs as a result of prolonged vibration during machining applications, or when the threads become worn after extended use over time.

Does a gage edge fit into the remaining threads?

The gage edge will fit perfectly into the remaining threads when you have the correct gage blade selected (there will be no gaps between the gage's teeth and the edge of the screw's or bolt's remaining threads).

How do threaded parts work?

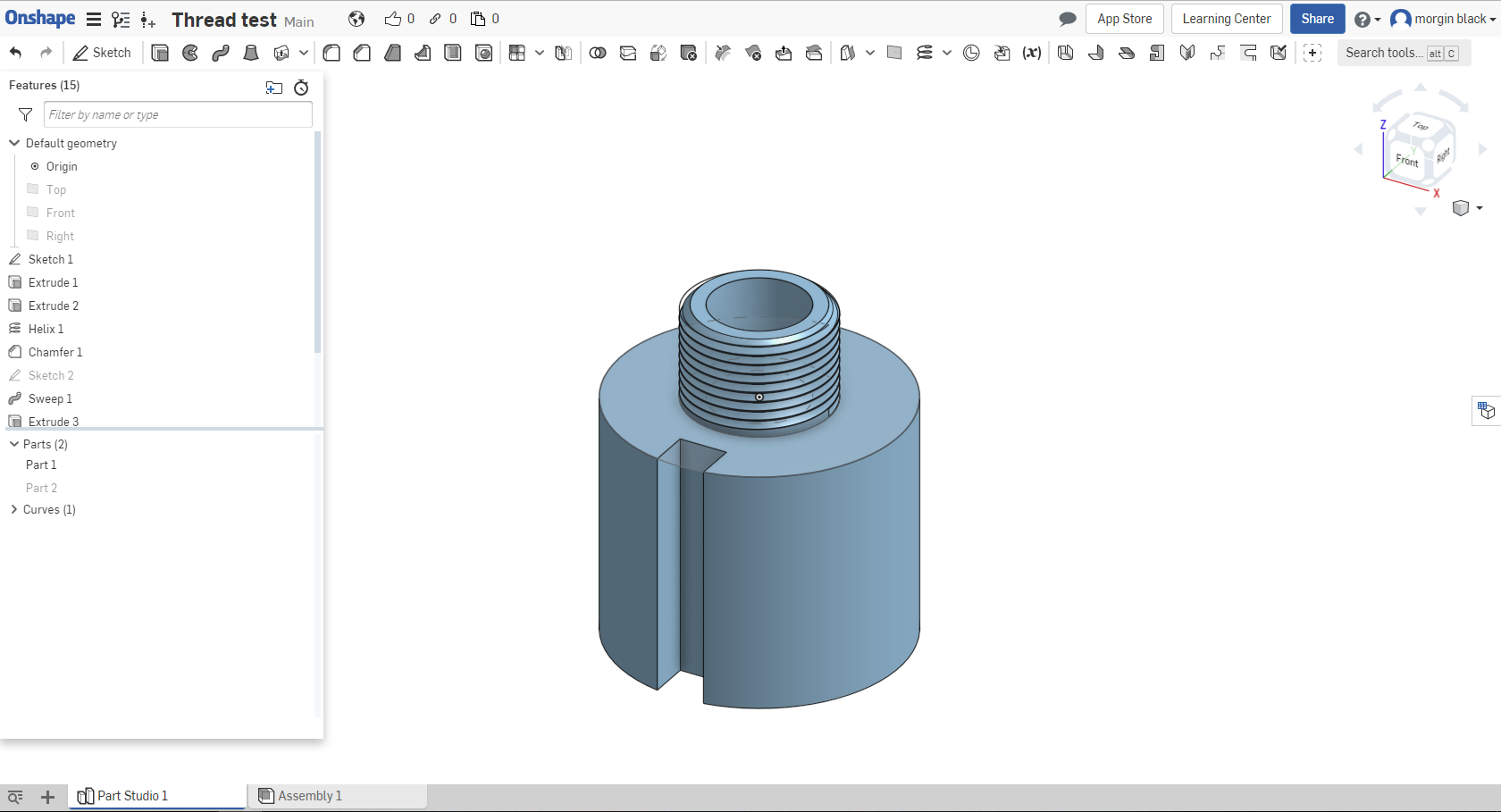

They are twisted by hand, and slowly work their way into hole being tapped. Threaded parts such as bolts, shafts, and other similar parts use dies to cut the threads. This is done in a similar manner as a tap, but the shaft of the part threads through the die as it cuts the threads.

What happens when you strip a bolt?

When you strip one out or break a bolt inside the hole, the threads are damaged. In some cases you can re-tap the threads with good results, but if the fastener is under high load or critical, then you will likely have to go to the next size up. These holes use taps, which cut threads into the metal.

What is a taper tap?

The taper tap is the most common tap design. This is the style used for creating new threaded holes. The first 8 to 10 cutting flutes of the tap are not full, they gradually build up to the full thread size. The taper is there to guide the tap in the hole and to slowly cut the threads in fresh material.

Why do taps have tapered flutes?

The tapered flutes help ensure that the tap is centered and vertical. We ran the tap all the way through the part, so that the bottom threads were touched by the full flutes of the tap. The chips in the relief grooves of the tap are called swarf, they should be cleaned off before putting the tap away.

How many flutes does a plug tap have?

The plug tap is in the middle, it uses 3-5 gradual flutes. Each tap style serves a different purpose. From the left- taper, plug, and bottoming. If you are repairing damaged threads, either of these taps will usually work, unless it is a blind hole, in which you need to use a bottoming tap.

What happens if threads don't match?

Some pitches overlap different sizes, so you have to use the chart to determine what size fastener you have. Thread size and pitch is critical to this type of repair. Using this style of pitch gauge, you can determine exactly what you have.

How to get chips out of a thread?

Once the threads are cut, you need to clean out the hole. Spray it with compressed air, brake cleaner or lubricant to get all the chips out.

How to repair a hole in a bolt?

Choose a thread tap that matches the original bolt's thread pattern. Dip the tap in a light oil; motor oil works great for this. Work the tap into the hole until hand-tight. Place a wrench on the square end of the thread tap and run the tap into the damaged hole a couple of times.

How to tighten a bolt?

Press the bolt into the hole and twist clockwise. The bolt should turn easily. Once hand-tight, place the proper sized wrench or socket on the bolt's head and tighten as needed. When applicable, use a torque wrench and turn the bolt clockwise until it reaches the manufacturers recommended torque limit.

How to tell if a bolt hole is damaged?

Symptoms of a badly damaged bolt-hole range from a bolt that loses grip when applying moderate torque, to one that spins freely. The repair methods also vary greatly. When used appropriately, a simple chemical thread-filler works remarkably well. The popular thread-insert repair method returns a hole to its original size. Sometimes using a longer nut and bolt solves the thru-hole issues that cause inserts problems, such as insert pass through.

What is thread repair insert?

A thread-repair insert acts as a bushing between an over-sized hole and a properly sized bolt. A popular insert has an expanding coil design; others look like a standard bushing. A basic thread repair kit contains a thread tap, insert and an installation tool. Thread-insert installation requires a properly sized drill bit.

How to stop a bolt from vibrating?

Use thread-locking material on bolts susceptible to vibration. After the thread-locking material dries, a semi-permanent bond forms, preventing the bolt from vibrating loose. When working with a blind hole application, apply the thread-locking material to the bolt's male threads. Excess thread-locker in a blind hole can stop the end of the bolt from bottoming out. In thru-hole applications, cover the hole's female threads before inserting the bolt.

How to install a thread locker?

Place thread locker, if manufacturer recommended, on the appropriate surface. Screw the insert into the hole, stopping when the insert bottoms out. Remove the installation tool. Complete the repair and install a new bolt.

What does tap do in a hole?

A tap creates female threads in a hole.

What is thread repair insert?

Thread-repair inserts come in a variety of materials and in a myriad of designs from domestic and overseas manufacturers. Timed thread body inserts, wire coil inserts and keyed inserted make up the three major families of thread inserts you’ll likely encounter.

How to repair M10x1.25 thread?

For an M10x1.25 thread repair with a Keensert, a 12.5mm drill would be used for the M14x1.5 tap. The M14x1.5 tap would have a major diameter up to 14.4mm (an M10 repair with an S.T.I. tap would only have a 11.787mm major diameter). That’s a much bigger hole which can be beneficial in some application where severe corrosion is prevalent in the original threads. The Keensert would then be threaded into the drilled, tapped and cleaned hole with the Keensert installation tool. Thread locking compounds can be used due to its solid body design. Once set in position, the installation tool is then used to drive in the four key stakes into position. This provides the ultimate mechanical locking of the insert in place. Hence, this design sports exceptional resistance to vibration. Now the downside. The massive outside diameter of the insert makes it unviable in applications where the material around the original threaded hole is limited, such as any “thin-wall” castings. Second, the cost for a standard-steel Keensert is about 4.5 times that of a HeliCoil and more than double the cost of a TIME-SERT. If you want a stainless-steel Keensert, the cost goes through the roof being about 25 times the cost of a HeliCoil.

What size drill do I use for a M10x1.25?

First, you would drill the hole with a 10.25mm drill (a standard M10x1.25 thread would use a much smaller 8.75mm drill). Then you would use an M10x1.25-S.T.I. tap. This S.T.I. version of the tap will have a major diameter of up to 11.787mm, whereas a standard M10x1.25 tap is about 1.5mm less in diameter.

How hard is it to drill a stripped hole?

How easy or how hard usually depends on the access to the stripped hole. If you can take off the entire header and get enough access to fit a cordless drill in the area to drill out the hole before tapping, it pretty easy. I;'m guessing it would probably be an M8x1.25 thread. Compare the size and thread on one of the good bolts to a know M8x1.25 bolt to confirm.

Can you have a thread failure in the same hole again?

Done right, you’ll never have a thread failure in the same hole again.

Is stripper thread more common than ever?

As a result, it’s no surprise that strippers are more common than ever before. Since most of the threads on today’s vehicles are made of materials with just one-third to one-half the hardness of grey cast iron, it’s no wonder that more threaded holes experience thread damage than ever before.

Can Keensert be threaded?

That’s a much bigger hole which can be beneficial in some application where severe corrosion is prevalent in the original threads. The Keensert would then be threaded into the drilled, tapped and cleaned hole with the Keensert installation tool. Thread locking compounds can be used due to its solid body design.