Thread: Shaft build up and repair??

- Get a good drawign of the shaft- if one exists. If not, make a drawing.

- Determine the loads on the shaft. This will include any bending loads from gearing or belting or other components mounted ont he shafting as well as the torque. ...

- Try to determine what material the shaft is made of. ...

How do you fix a broken thread on a bolt?

The first step in the repair is to enlarge the bolt hole with a 2532-inch drill bit, making room for the larger shoulder of the new threaded insert tool. We checked our progress often, and stopped when we hit the top of the threads.

How do you fix a chipped thread on a threaded shaft?

Spray it with compressed air, brake cleaner or lubricant to get all the chips out. Fixing threads on a threaded shaft follows much of the same path; however there are few minor differences.

How do you repair damaged threads on a car?

All you need to repair damaged threads is some patience and a tap and die set. Threaded holes can be found in all areas of your vehicle, from the engine to the chassis. These holes are tapped with the correct size of threads for the job at hand. When you strip one out or break a bolt inside the hole, the threads are damaged.

What are thread-repairing inserts?

Instead, the solution for stripped threads are inserts. Thread-repair inserts come in a variety of materials and in a myriad of designs from domestic and overseas manufacturers. Timed thread body inserts, wire coil inserts and keyed inserted make up the three major families of thread inserts you’ll likely encounter.

How do threaded parts work?

How to get chips out of a thread?

What is a taper in a blind hole?

What is a taper tap?

Why do taps have tapered flutes?

How many flutes does a plug tap have?

What happens if threads don't match?

See more

About this website

How do you fix a threaded shaft?

1:234:26Repairing Damaged Axle Shaft Threads - YouTubeYouTubeStart of suggested clipEnd of suggested clipNow we're gonna go ahead and rethread this guy or fix the threads or hopefully fix the threads. SoMoreNow we're gonna go ahead and rethread this guy or fix the threads or hopefully fix the threads. So my special tool for this is going to be a very large Kinetics Cobra. Plier.

Can you fix damaged threads?

Damaged threads on a screw or bolt can often be fixed by running a die over it, and if a thread's damage is minimal, it may be possible to reform the threads by running a nut up and down them, though that runs the risk of the nut fusing to the thread (galling).

How do you Rethread stripped threads?

1:072:46How to Fix Stripped Bolt Hole Threads on Your Car - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo basically we get our long extension stick it in the hall with a threading tool. And start to turnMoreSo basically we get our long extension stick it in the hall with a threading tool. And start to turn the ratchet. To eat the threads. In. And when it starts to get snug.

Can you Rethread a hole the same size?

In most cases, parts like these can be re-threaded, but they must be done with the same size threads, you can't cut the next size smaller threads. This only works for non-critical, non-high load components. If the threads got dinged or flattened, then this will work.

Can you use Loctite on stripped threads?

Loctite® Form-A-Thread® It restores worn, stripped or damaged threads and eliminates future corrosion, galling, seizing, and rust, and allows up to 128 ft. lbs. of torque between -65°F to 300°F. It permanently repairs stripped threads and fasteners in five minutes (up to SAE Grade 5 English and 8.8 metric).

How do you fix male pipe threads?

0:275:22Repairing pipe threads - YouTubeYouTubeStart of suggested clipEnd of suggested clipWe want to make sure the tool is lubricated. This is what they call high speed steel very brittleMoreWe want to make sure the tool is lubricated. This is what they call high speed steel very brittle it's easy to break even though it looks pretty tough with enough torque you can shatter this steel.

How do you make a new thread in a hole?

1:205:05HOW TO TAP NEW THREAD FOR A BOLT - YouTubeYouTubeStart of suggested clipEnd of suggested clipIt's all you want to do is simply put through a pilot hole. And then we'll put the full sliceMoreIt's all you want to do is simply put through a pilot hole. And then we'll put the full slice through that making sure that's in one. Position. Just like that alright.

How do you fix a thread without a tap?

0:442:11Easily repair a cross threaded hole without a tap! - YouTubeYouTubeStart of suggested clipEnd of suggested clipSlide to the bolt will make our act as a cutter when it gives it a relief for the material to getMoreSlide to the bolt will make our act as a cutter when it gives it a relief for the material to get into the slide. Once you run that through the thread your bolts for reading with its.

How do you fix a screw that won't tighten metal?

0:177:5413 Annoying Loose Screws Around the House & How to Fix ThemYouTubeStart of suggested clipEnd of suggested clipAnd you can also apply a product like the thread stopper tape wrap it around a couple of times onMoreAnd you can also apply a product like the thread stopper tape wrap it around a couple of times on the threads. And that will hold it in there a lot easier and a lot longer.

How do you fix a stripped screw hole in metal?

How Do You Fill Stripped Screw Holes in Metal?Use a specialized bit to enlarge and thread the hole, then insert a new screw.Drive a larger-diameter, self-tapping screw into the hole.Fill the hole with metal epoxy, then drive the original screw back into the hole.More items...

How do you fix a stripped screw hole?

0:446:22How to Fix Stripped Screw Holes - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd get some toothpicks for this hole right here three ought to do it just place them in the hole.MoreAnd get some toothpicks for this hole right here three ought to do it just place them in the hole. Like that break off the excess.

What is a Rethreading tool?

Taps and dies are metal threading tools used to cut and restore internal and external threads precisely.

How do you make threaded holes smaller?

Using Matches or Toothpicks The most common – albeit not professional – way to fill screw holes when you need to make them smaller is by using matches or toothpicks as shims. This method has been used for a long time, but should only be used for holes that won't hold any great weight.

How do you make a bolt fit into a bigger hole?

Use Filler to Fill the Screw HoleFill the hole with liquid glue — For this, you can use wood glue or Elmer's glue (Amazon affiliate link). ... Fill stripped out the hole with toothpicks — Yes, toothpicks! ... Start anew with your screw — Now that the hole is filled, you can completely start fresh and redrill the hole.

How do you Rethread a spark plug hole?

0:322:45How to Fix Stripped Spark Plug Hole in Your Car - YouTubeYouTubeStart of suggested clipEnd of suggested clipStart turning it to start. It. Then very slowly turn it to cut the threads. You don't want to breakMoreStart turning it to start. It. Then very slowly turn it to cut the threads. You don't want to break anything you want to do it nice and smooth. And once it bottoms out then you are thriving.

Does it matter which side you tap a hole from?

Doesn't matter where they tap from as your asking for threads "all the way through". Don't forget that there should be thread relief on both sides of the threaded hole feature.

Loctite Stripped Thread Repair Tip | Fix My Hog | Fix My Hog

How-to video on stripped thread repair. Form A Thread from Loctite makes it an easy fix. Loctite has a great product for motorcycle repair.

How to repair a stripped thread?

Similarly, when threads are stripped out of a hole, there are a number of approaches one can take to repair them. Drilling out the hole and tapping it with a larger diameter thread is one option, provided there is room for a larger fastener. When creating a new, larger tapped hole isn't optimal or possible, use of a thread repair kit is recommended.

Why does my thread get damaged?

Typically, thread damage is caused when a tap or fastener breaks in a hole, when a fastener is installed incorrectly , when incorrect bolt torque is used, or when thread fretting occurs as a result of extended or extreme vibration ...

What is a thread repair kit?

They may also be used to create strong threads in soft materials including aluminum. Thread repair kits consist of a tapping tool, an insertion tool, and thread inserts. A tap wrench and drill will also be necessary when using a thread repair kit. The drill bit is not always included in the kit. The most popular type of thread insert used in ...

What to do when you have a tapped hole?

When creating a new, larger tapped hole isn't optimal or possible, use of a thread repair kit is recommended. Thread repair kits allow you to remove the damaged threads that are stuck in a hole and replace them with new threads of the same diameter.

Why use helical thread insert?

An installed helical threaded insert can provide a more secure threaded connecting point and overall stronger threads.

How to break off a tang?

Break off the tang where the thread insert wire returns across the hole (A hex tool can be inserted through the new thread to rest against the tang and it typically will snap off easily with the light tap of a hammer).

What is the tension between the insert and the walls of the hole?

The tension between the insert and the walls of the hole helps to keep the insert in place and keep it from unthreading. The helix has a small return at one end that engages with the kit's included insertion tool, allowing the insert to be screwed into the hole.

What is thread repair insert?

Thread-repair inserts come in a variety of materials and in a myriad of designs from domestic and overseas manufacturers. Timed thread body inserts, wire coil inserts and keyed inserted make up the three major families of thread inserts you’ll likely encounter.

How to repair M10x1.25 thread?

For an M10x1.25 thread repair with a Keensert, a 12.5mm drill would be used for the M14x1.5 tap. The M14x1.5 tap would have a major diameter up to 14.4mm (an M10 repair with an S.T.I. tap would only have a 11.787mm major diameter). That’s a much bigger hole which can be beneficial in some application where severe corrosion is prevalent in the original threads. The Keensert would then be threaded into the drilled, tapped and cleaned hole with the Keensert installation tool. Thread locking compounds can be used due to its solid body design. Once set in position, the installation tool is then used to drive in the four key stakes into position. This provides the ultimate mechanical locking of the insert in place. Hence, this design sports exceptional resistance to vibration. Now the downside. The massive outside diameter of the insert makes it unviable in applications where the material around the original threaded hole is limited, such as any “thin-wall” castings. Second, the cost for a standard-steel Keensert is about 4.5 times that of a HeliCoil and more than double the cost of a TIME-SERT. If you want a stainless-steel Keensert, the cost goes through the roof being about 25 times the cost of a HeliCoil.

What size drill do I use for a M10x1.25?

First, you would drill the hole with a 10.25mm drill (a standard M10x1.25 thread would use a much smaller 8.75mm drill). Then you would use an M10x1.25-S.T.I. tap. This S.T.I. version of the tap will have a major diameter of up to 11.787mm, whereas a standard M10x1.25 tap is about 1.5mm less in diameter.

How hard is it to drill a stripped hole?

How easy or how hard usually depends on the access to the stripped hole. If you can take off the entire header and get enough access to fit a cordless drill in the area to drill out the hole before tapping, it pretty easy. I;'m guessing it would probably be an M8x1.25 thread. Compare the size and thread on one of the good bolts to a know M8x1.25 bolt to confirm.

Can you have a thread failure in the same hole again?

Done right, you’ll never have a thread failure in the same hole again.

Is stripper thread more common than ever?

As a result, it’s no surprise that strippers are more common than ever before. Since most of the threads on today’s vehicles are made of materials with just one-third to one-half the hardness of grey cast iron, it’s no wonder that more threaded holes experience thread damage than ever before.

Can Keensert be threaded?

That’s a much bigger hole which can be beneficial in some application where severe corrosion is prevalent in the original threads. The Keensert would then be threaded into the drilled, tapped and cleaned hole with the Keensert installation tool. Thread locking compounds can be used due to its solid body design.

What bit did Bouchard use to clean out the OE threads?

8. Bouchard used a 21/32 bit next to clean out the stripped OE threads. He drilled approximately 5 inches in, stopping when he felt the bit reach solid metal. We've taped the new timing cover seal to keep shavings out of the engine.

What belt sander grinds the shoulder off the bolt?

4. Using our Eastwood belt sander, Bouchard grinds the shoulder off the bolt, making it a smaller diameter than the ID of the damper.

Where is the damper bolt on a keyless crankshaft?

The damper bolt is long and thread engagement is at the back of the bore, rather than at the front, so thread engagement is minimal from the factory. Combine that with a torque-to-yield bolt on a keyless crankshaft, and it's easy to see why broken crank threads are becoming a common problem.

How to repair a damaged shaft?

Worn and damaged shafts are conventionally repaired using a hot process (welding/machining or hot metal spray/machining). If not carefully controlled, these conventional methods will cause residual damage to the shaft. They also require the disassembly of the machine. There are problems associated with welding and thermal spraying. Welding can create heat stresses that will tamper and distort the metal, lowering its load bearing capacity. Metal spraying can only be used to repair damage up to a few 1000s of an inch. These problems and limitations can be avoided by using a combination of polymer tehnology and proven Belzona application techniques.

Why are shafts worn?

In the mining industry, shafts can become worn or damaged due to vibration, friction and abrasive media. In the marine industry, gland packing and bushing damage to the shaft together with sand abrasion ...

What causes shafts to shut down?

In the marine industry, gland packing and bushing damage to the shaft together with sand abrasion and sea water exposure can lead to erosion-corrosion on shafts. Additionally, oversized keyways, a crucial component that connects the rotating equipment to the shaft, may cause shaft dysfunction. Worn and damaged shafts can shut down ...

What is shaft wear?

Shaft Wear and Damage. Shafts are a critical component of rotating equipment. Shafts are used to transmit power from one part to another or from a machine that produces power to a machine that absorbs power. Shafts are usually operated in immersed or semi-immersed conditions and are subject to damage by corrosion or chemical attack.

Can thermal spraying damage metal?

There are problems associated with welding and thermal spraying. Welding can create heat stresses that will tamper and distort the metal, lowering its load bearing capacity. Metal spraying can only be used to repair damage up to a few 1000s of an inch.

How do threaded parts work?

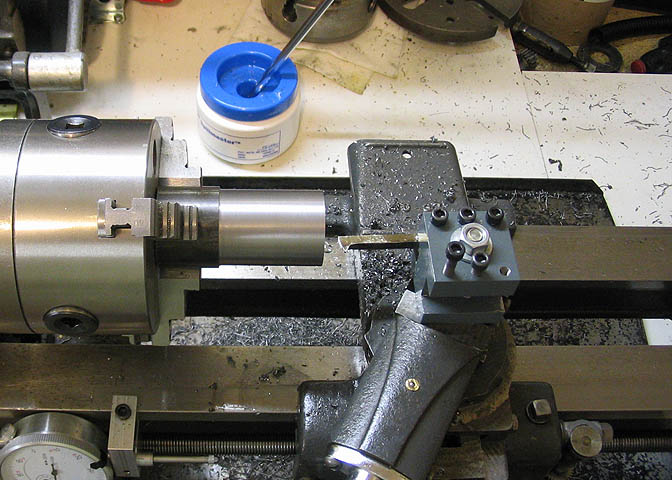

They are twisted by hand, and slowly work their way into hole being tapped. Threaded parts such as bolts, shafts, and other similar parts use dies to cut the threads. This is done in a similar manner as a tap, but the shaft of the part threads through the die as it cuts the threads.

How to get chips out of a thread?

Once the threads are cut, you need to clean out the hole. Spray it with compressed air, brake cleaner or lubricant to get all the chips out.

What is a taper in a blind hole?

The taper is there to guide the tap in the hole and to slowly cut the threads in fresh material. While this is great for through-holes, where the backside of the hole is open, these only get part of the job done when you are working with a blind hole, where the hole is closed. For that, you need a bottoming tap.

What is a taper tap?

The taper tap is the most common tap design. This is the style used for creating new threaded holes. The first 8 to 10 cutting flutes of the tap are not full, they gradually build up to the full thread size. The taper is there to guide the tap in the hole and to slowly cut the threads in fresh material.

Why do taps have tapered flutes?

The tapered flutes help ensure that the tap is centered and vertical. We ran the tap all the way through the part, so that the bottom threads were touched by the full flutes of the tap. The chips in the relief grooves of the tap are called swarf, they should be cleaned off before putting the tap away.

How many flutes does a plug tap have?

The plug tap is in the middle, it uses 3-5 gradual flutes. Each tap style serves a different purpose. From the left- taper, plug, and bottoming. If you are repairing damaged threads, either of these taps will usually work, unless it is a blind hole, in which you need to use a bottoming tap.

What happens if threads don't match?

Some pitches overlap different sizes, so you have to use the chart to determine what size fastener you have. Thread size and pitch is critical to this type of repair. Using this style of pitch gauge, you can determine exactly what you have.