How to Repair a Broken Printed Circuit Board

- Mix the epoxy according to the manufacturer's instructions, and apply it sparingly to one side of the PCB.

- Cut through the broken copper traces using a razor knife. ...

- Plug the soldering pencil into a 110-volt receptacle and wait for it to get hot. Clean the hot soldering tip by wiping it on a wet soldering sponge.

- Apply a fresh "tinning" coat of rosin-core solder to the clean soldering pencil tip. A properly tinned tip will be a bright silvery color.

- Apply the rosin-core solder to the bared copper traces on the printed circuit board. Use care to apply no more heat than is necessary to melt the solder.

- Cut pieces of the 18-gauge copper wire that are long enough to span the cut traces, and tin these short lengths of wire with rosin-core solder.

- Pick up a piece of tinned wire with the tweezers and lay it carefully across one of the traces where you removed a loose section.

- Reassemble the device and test it to see if it works properly. ...

How do you troubleshoot a circuit board?

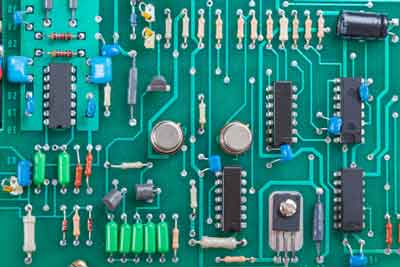

- Visual inspections — You can see a lot through a visual inspection. ...

- Physical inspections — With the board under load, a physical inspection may yield additional insights. ...

- Component testing — Delving deeper into the PCB’s many components, you can test the integrity of batteries, capacitors, resistors, inductors, diodes, switches, and transistors. ...

How do you repair a broken circuit board?

The likelihood of a soldered joint failing is increased by…

- Intermittent heating/cooling where expansion and contraction stresses connections, (power tools for example).

- Frequent and repeated moving of switches and other controls. ...

- Repeated pushing and pulling on plugs or cables physically flexes the joints between the component pins/legs and the circuit board (audio equipment for example).

How to solder on circuit board?

In general, the steps that need to be followed for it are as follows:-

- The first step in removing solder is to locate the solder joints on a circuit board. ...

- Next, use a wire stripper or knife to remove any excess plastic from the wires.

- Then, use an iron that has been heated up with solder-free flux on both sides of each joint until it melts away.

- Finally, clean up any remaining residue with acetone or alcohol and then

How to repair circuit boards in yourself?

Then, How to Repair Circuit Boards?

- Sharp knife or flathead screwdriver or fine sandpaper

- Copper foil

- Soldering gun

- Hot air gun

- Scissors

- Pen

- Cotton swab and rubbing alcohol

- Tweezers

- Paper clip

Can you solder a circuit board?

0:483:51How to Solder on Circuit Boards! - YouTubeYouTubeStart of suggested clipEnd of suggested clipWith any soldering you always want to apply heat to both the pad or in this case a through-hole andMoreWith any soldering you always want to apply heat to both the pad or in this case a through-hole and the leg. And let the solder do the work and fill the through-hole. Completely again apply heat.

What type of solder is best for circuit boards?

6 Best Solder for Electronics ReviewsKester Solder. First on our list is the Kester Solder, a 0.031 inches diameter steel-based solder with very high conductivity. ... Maiyum Solder Wire. ... SONEAK 60/40 Tin Lead Solder. ... Austor Solder Wire. ... Canfield Solder. ... Mandala Crafts Store Rosin Core Solder Wire.

How do you fix a solder on a circuit board?

1:382:54How To Fix Bad Solder Joint On Circuit Board (Using ... - YouTubeYouTubeStart of suggested clipEnd of suggested clipI will again for the tip at an angle until it's all melted. And use a solder sucker. And there youMoreI will again for the tip at an angle until it's all melted. And use a solder sucker. And there you see that the old solder has been sucked up.

Can you repair a cracked circuit board?

Luckily, it's possible to repair or remanufacture boards to make them like new again. This does one of two things. Either the board in question can be returned to its original device, making it function again. Or, it can be used in a completely different device, as a form of recycling if you will.

Do I need flux to solder?

When joining two metals in a soldering process, like used in PCB assembly, flux is required to achieve a true metallurgic bond. That ensures the solder joint doesn't crack or come loose even with the day-to-day wear-and-tear.

Can I use plumbing solder for electronics?

Typically, electrical solder contains rosin core flux; plumbing solder uses an acid-based flux. So it's not a good idea to use plumbing solder for electrical connections because the acid in the flux can damage the wiring and lead to connection failure.

Should solder be reheated on a circuit board keeping the same solder not re soldering with new metal?

Should solder be reheated on a circuit board (keeping the same solder, not resoldering with new metal)? Yes, once or twice using flux but only with prototype boards.

Can you solder over old solder?

Just heat the joint up with your torch, once the solder starts to melt use Channel locks to pull the fittings apart. Once the joint is apart, wipe as much old solder off as you can with a rag. Now you can start over. Clean, Flux, solder.

Can soldering flux damaged circuit board?

Why is it important to remove flux? Flux residues are acidic. They can corrode the components and damage the PCB over time. Keeping circuit boards clean is especially important for electronics used in high technology sectors, such as medical and aerospace.

Can you glue a circuit board back together?

0:408:09How to Repair a Cracked or Broken Circuit Board - YouTubeYouTubeStart of suggested clipEnd of suggested clipBoard is to glue the two halves. Back together. And what I used here was a special plastic bondingMoreBoard is to glue the two halves. Back together. And what I used here was a special plastic bonding epoxy it seems to stick real good to two circuit boards. And it's called plastic fusion by superglue.

How do you repair a circuit board without soldering?

1:523:29Surface Mount Repair Without Soldering - YouTubeYouTubeStart of suggested clipEnd of suggested clipThen take the new part and coat each of the legs with a small amount of surface mount componentsMoreThen take the new part and coat each of the legs with a small amount of surface mount components with your PIN or the needle. Now take this part and drop it in place on top of the pads.

How do you repair a circuit board?

How to Repair Damaged Printed Circuit Board PadsStep 1: Tidy Up the Damaged Track 1: ... Step 2: Tidy Up the Damaged Track 2: ... Step 3: Exposing the Track: ... Step 4: Sticking Copper Tape Over the Exposed Track: ... Step 5: Soldering the Copper Tape Joints: ... Step 6: Pierce to Make the Hole: ... Step 7: Solder in Your Component:More items...

Which type of soldering is used for electronic circuit?

For electronics soldering, the most commonly used type is lead-free rosin core solder. This type of solder is usually made up of a Tin/Copper alloy. You can also use leaded 60/40 (60% tin, 40% lead) rosin core solder but it's becoming less popular due to health concerns.

What type of solder do you use for electrical connections?

rosin-core solderThe best solder to use for tinning stranded copper wire is electrical-grade rosin-core solder. This is an acid-free solder that contains a flux in the core of the solder. Never use solder that contains acid to strip and tin wires, as this can damage the wire or its insulation.

What type of soldering iron should I use for electronics?

What Type of Soldering Iron Should I Use for Electronics. A pencil type is an ideal soldering iron for small electronics or more detailed soldering applications like circuit boards.

What solder is good for small electronics?

WYCTIN 60/40 Tin-Lead Based Rosin Core The 60/40 tin-lead ratio on this solder is ideal for most electrical soldering work. It's also better for use, especially on small, indoor workstations, as it produces less or even no fumes when heated.

How to remove a broken pad?

If it doesn’t come, continue to apply heat for a few more seconds and then try again. If a pad has been damaged by heat, it’s best to use a sharp knife to carefully remove it.

Why is it important to be an electronics engineer?

What is more important for electronics engineers is to be proficient in repair circuit boards, which will have a significant contribution to the accumulation of experience in their careers.

Does copper tape melt?

Here are a few tips and warnings about this part of the process: Copper tape melts quickly at soldering temperatures , so don’t begin until you’re certain that you can finish this part of the process in one go. Use as little heat as possible and work deliberately, but quickly, to reduce the amount of heat applied. 5.

What does it mean when a solder joint is broken?

A broken solder joint is where the solder connecting the component pin or leg to the copper track on the circuit boards becomes damaged. Bad contact with the copper track of course means a poor connection (intermittent problems) or no contact at all (device stops working altogether).

Why does solder crack?

Broken solder joints are often caused by…. Excess heat, where the pins/legs and the solder surrounding them expand and contract at different rates in use eventually causing cracking and erosion of the solder. Fatigue, where the connection between the component pin/leg and the copper track cracks due to repeated movement or flexing.

What is a cracked solder joint called?

A cracked, fractured or broken solder joint is sometimes (erroneously) called a ‘cold’ or ‘dry’ joint (but both those terms relate to problems with soldered joints from the start). Calling it a ‘broken solder joint’ works for me, and is a better description for this very common electronic failure problem.

Why do machines vibrate?

Machines that vibrate a lot because they use a big, fast motor. Vibration stresses the joints between the component pins/legs and the circuit board, (washing machines for example). Devices that move around a lot.

Can you solder without flux?

First, always use a proper when soldering (and not one designed for copper plumbing pipework). This magical paste will chemically clean the joint making the solder ‘stick’ much better. In fact, soldering without flux is virtually impossible (trust me on this, I know!).

What is solder pad?

A solder pad is the part of a printed circuit board — or PCB — that supports the pins of components like transistors and chips. Typically, when devices break or components are removed from PCBs, it can result in damaged and missing solder pads.

Can you use open air to cure a lap joint?

You can either use open air to cure it, or you can use an oven — but be sure to follow all manufacturer guidelines. Soldering the new pad/trace to the conductor: Use Kapton tape to place and hold the replacement pad. Use the appropriate solder alloy to make a lap joint.