How do you check for circuit board problems?

How to Find a Fault in a Circuit BoardMake sure it's plugged in tight and the pins are clean. ... Check to see if all the circuit boards (CB) are plugged in tightly. ... Check individual plug-in components. ... Look for water or foreign objects anywhere on the circuit board. ... Check secondary wiring plugs.More items...

Can you repair circuit boards?

Luckily, it's possible to repair or remanufacture boards to make them like new again. This does one of two things. Either the board in question can be returned to its original device, making it function again. Or, it can be used in a completely different device, as a form of recycling if you will.

How do you test a circuit board?

To test circuit board properly, touch the multimeter probes to the test points present on the board. Make sure while playing out this step you have your hands on the plastic portion of the probes. You can then go on to check either the voltage or resistance.

How do I know if my circuit board is damaged?

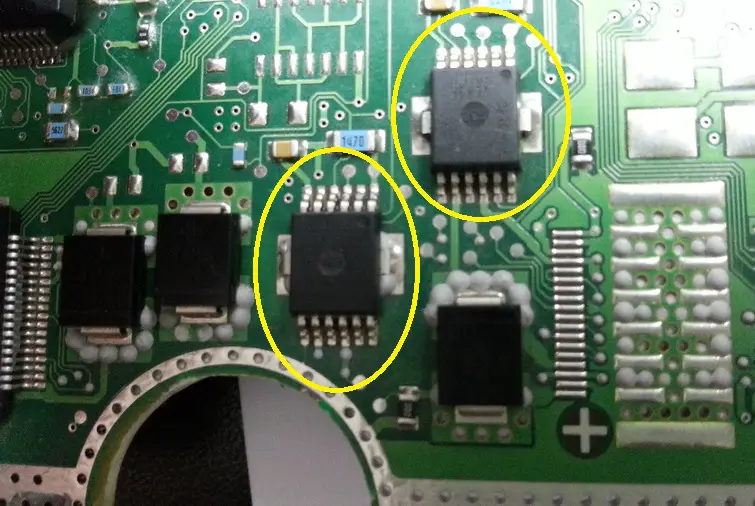

Examine the circuit board and search for signs such as crushed components, bulges, damaged wires, cracks, misplaced or extra solder, burn marks and scratches that indicate that the board is either bad or requires replacement and professional assistance.

How much does it cost to repair a circuit board?

The price to repair an HVAC circuit board is $100 to $600. This job often includes replacing it. HVAC circuit boards usually need repair or replacement due to other electrical problems in the system, such as: Dirty or incorrect fuses.

Can you fix a burnt circuit board?

Scrape the burned material away, up to the ends of both sides of the circuit trace, so you can see clean, shiny connection points. Use alcohol and a cotton swab to clean the area, including the shiny ends of the circuit traces. Mix a small amount of circuit epoxy in a plastic cup, according to directions.

How can you tell if a circuit board is fried?

Physical Damage Smelling smoke or seeing charred circuitry are obvious signs, but also examine the capacitors, which are cylindrical in shape and placed in various locations on the board. Their job is to filter the electricity going to various components on the board, and power surges or overheating can damage them.

How do I find a short in a circuit board?

To test a circuit board for a short circuit, you need to check the resistance between different points in the circuit. If visual inspection doesn't reveal any clues as to the location or cause of the short circuit, grab a multimeter and try to track down the physical location on the printed circuit board.

What causes circuit boards to fail?

Environmental Factors: Exposure to heat, dust and moisture, accidental impact (drops and falls), and power overloads/surges can be causes of circuit board failure. However, the most damaging cause of premature circuit board failure is electrostatic discharge (ESD) at the assembly stage.

What are two common problems when troubleshooting a circuit board?

Common Printed Circuit Board ProblemsBurnt Circuit Board. Table of Contents. ... Poorly Manufactured Components. Poor manufacturing is another common problem with PCBs. ... Bad Soldering. Poor soldering can cause many issues in a PCB. ... Environmental Factors. ... Age. ... Plating Voids. ... Insufficient Copper-to-Edge Clearance. ... Slivers.More items...•

How do you fix a broken circuit board?

2:475:36HOW TO FIX CRACK CIRCUIT BOARD- Soldering TECH Tips 11YouTubeStart of suggested clipEnd of suggested clipDon't hold the metal part. And then what you want to do is just lay it right. There. You just slideMoreDon't hold the metal part. And then what you want to do is just lay it right. There. You just slide it.

How do you repair a circuit board without soldering?

1:523:29Surface Mount Repair Without Soldering - YouTubeYouTubeStart of suggested clipEnd of suggested clipThen take the new part and coat each of the legs with a small amount of surface mount componentsMoreThen take the new part and coat each of the legs with a small amount of surface mount components with your PIN or the needle. Now take this part and drop it in place on top of the pads.

How do you repair a soldered circuit board?

1:2611:48How to Solder - Beginner Guide to Soldering Components on TV PartsYouTubeStart of suggested clipEnd of suggested clipPlace the iron tip on the bottom of the leg. And the pad on the board then touch the solder to theMorePlace the iron tip on the bottom of the leg. And the pad on the board then touch the solder to the iron. And slide the iron tip up the leg and away from the pad Legg.

How do you fix a corroded circuit board?

Use cotton swabs and a cleaning solution such as isopropyl alcohol, baking soda and water, or even vinegar to clean it. Gently apply the solution to the affected area and wipe back and forth until the corrosion is removed. If necessary, leave some of the solution on the corroded area and wipe it off later.

Why You Need to Know How to Repair Circuit Board?

For professional electronics engineers and DIY amateurs, circuit boards (PCB) are something they must face. It is necessary to understand circuits' running and how to repair circuit boards.

How to secure copper tape to a pad?

Find a hard implement with a rounded-off end, like a pen or another simple tool. Press down on the area that you’ve just soldered and rub firmly to ensure that the copper tape is securely affixed to the entire pad area. The adhesive should still be tacky after you’ve applied heat to the area.

How to cover a hole in a track?

After you’ve removed the damaged track and cleaned off the area, it’s time to place your adhesive copper tape over the top of the area that you’re working with. Your tape should overlap with the existing track and cover the existing through-hole and a portion of the area surrounding it.

How to diagnose a PCB?

Sometimes, diagnosing a damaged PCB requires an oscilloscope to probe the signal strengths and waveforms at various points to test for continuity of the circuit across the board. Other times, it’s just a matter of looking for a burned area that indicates that a failed component or a pad or trace needs to be replaced and rejoined to the existing track on the board.

What to do if a pad is damaged by heat?

If a pad has been damaged by heat, it’s best to use a sharp knife to carefully remove it. Your priority is to limit the amount of damage that you do to the track and the other nearby features while still freeing the board from any residue.

How to remove a broken pad?

If it doesn’t come, continue to apply heat for a few more seconds and then try again. If a pad has been damaged by heat, it’s best to use a sharp knife to carefully remove it.

What skills are needed to repair circuit boards?

Knowing the theoretical knowledges of how to repair circuit boards, a series of basic soft and hard skills are required, including excellent hand-eye coordination, great patience and attention to detail. In the final analysis, the most important thing is practice, again and again.

What is a CADENCE PCB?

Cadence PCB solutions is a complete front to back design tool to enable fast and efficient product creation. Cadence enables users accurately shorten design cycles to hand off to manufacturing through modern, IPC-2581 industry standard.

What does it mean when a fuse breaks?

If the fuse is replaced and immediately breaks after power-up, it means other components are shorted and draining a huge amount of current. A voltage of 0V, or below Vcc, at the output often means that the regulator or a component along the voltage rail has a short circuit.

What is the risk of a RS485?

Circuit boards with communication ports like Ethernet and RS485 have an increased risk of failure. When communication failure is detected, check for burns or cracked communication ICs or protective components like Zeners.

What happens if I/O is protected by fuses?

If the I/O is protected by fuses, Zener diodes, or varistors, ensure that they are functioning well. If so, the logic IC or the microcontroller is likely damaged. The only way to find out is to replace the parts with good ones.

What happens when I/O ports are damaged?

The I/O are also common points of failure. Damage on I/O ports seldom shuts down the whole circuit, but it usually results in anomalies in the system. For example, an alarm controller that always senses an open door even if it’s closed or a motor that is continuously activated.

How to tell if a power supply is burnt?

Look for a burnt spot, particularly on the power supply module or I/O and connectivity ports. Pay attention to cracked ICs, broken traces, and blown capacitors. Sometimes, you could trace the damaged components by their acrid scent.

What happens when a circuit board stops working?

When a circuit board suddenly stops working, there are sometimes obvious signs of what went wrong. You’ll need to rely on your vision to spot faulty components or broken traces. Often , circuit boards deployed in the field are damaged by electrical surges and there are telltale signs on the PCB.

How to compare the signatures of a PCB?

But if you have a fully functional PCB take all its signatures by using multimeter .Voltage resistance current and inductance of every component is computed and then is compared with all the signatures of defective PCB (Printed Circuit Board).

What is PCB design?

In hardware development of electric al circuit, to get all the components of circuit on one single place or board is called PCB designing. Printed Circuit Board (PCB) is the common name that is used for these electrical boards. In history, PCBs were been developed by going through a complicated procedure of point-to-point wiring ...

Why are PCBs multi layered?

Older PCBs were single layered but these days multi layer PCBs are present and used in the market .PCBs are multi layered because these days complexity of electrical circuit is also increased.

What are the elements of an electrical circuit?

Voltage, current, resistors, capacitors and inductors are considered as primary elements of any electrical scenario called circuit. Electrical current can be in two forms either a sinusoid AC (alternating) current or simply a straight line called direct or DC current. In hardware development of electrical circuit, ...

What is the second stage of a circuit?

Second stage is to detect location of the faults. It deals with minute analysis to pinpoint the faulty component. But not like functionality test it performs tests only on input and output stages. In third stage new functional components are placed in circuit after removing the faulty components.

What is the power of a PCB?

Before getting into details of printed circuit board (PCB), there are some basics you need to know about circuits. Electricity: It is the power provided to every instrument ranging from small lights to heavy machinery. Electricity is just a flow of electron from one level to other (upper level to lower mostly).

Can you identify a PCB signature?

In an electrical circuit all the components are either in series, parallel or a mixed combination (Series-Parallel) both so it become impossible to identify their signatures so the only suitable solution in this scenario is to take a new PCB and compare the signatures of defective one with the signatures of functional one.

How Do the Big Boys Do It?

Professional repair houses and repair centers that fix boards all the time need better solutions than a scope and a DMM. In situations where faulty PCBs come in a steady stream, and with the increased emphasis on efficiency and reduced costs, universal automated test systems have replaced individual test instruments. PC-based in-circuit testers perform both a powered in-circuit logical test of digital and many analog ICs, as well as V-I signature analysis of the chips, using a variety of test clips.

What to do if a capacitor leaks?

If leaks, cracks, bulges, or other signs of deterioration are evident, replace the capacitor with an equivalent type and voltage rating. Capacitors have a limited life and are often the cause of a malfunction. Look for broken leads on the components.

What does a dull surface mean on solder joints?

Good solder joints always look smooth, bright, and evenly flowed. A dull surface can suggest a defective joint. Are there any solder bridges between tracks? Reversed or incorrect components?

Why is the methodical use of relevant test tools important?

The methodical use of relevant test tools helps investigators to identify the cause of failure quickly and accurately, and thereby speed up PCB repair.

Why are circuit boards so complicated to repair?

Circuit boards are more complicated to repair today than even a few years ago. Manufacturing mistakes and in-service component failures have become commonplace. Older circuit boards can malfunction due to components that fail — notably electrolytic capacitors — but new ones (assuming the layout is correct) might not work due to manufacturing errors, parts poorly or incorrectly soldered, solder bridges, etc.

Why do resistors have a diagonal line?

A pure resistor would give a diagonal line whose slope is proportional to the resistance because the current is proportional to the applied voltage. More complex curves are obtained with frequency-dependent components such as capacitors and inductors, and also for non-linear devices such as diode and transistor junctions.

How to check for a short circuit?

Check for loose connectors or components in sockets, which can often get dislodged in shipping. Look for burned or damaged parts , or solder bridges causing a short circuit of signal or power lines. This is where a high-power digital microscope is really useful (see Figure 3 ). Visual inspection is an essential first step in troubleshooting.

What is the red probe on a circuit board?

This is the first and basic step in circuit board testing. For this step to work out, you first need to observe the polarity and then probe in the multimeter. Every multimeter device comes with two types of probes, namely red and black. While the red one is the positive probe, the black one is the jack at the end of the probe wire.

Why are multimeters used in electrical equipment?

One of the main reasons why Multimeter are widely used today is because they can find faults within a piece of electrical equipment very easily.

Why is PCB troubleshooting important?

Troubleshooting a PCB is very important nowadays. It is because, with the rising demand for electrical appliances, the supply for circuit boards has also increased. Thus, a minor distraction in the board can make it non-functional or damage the components. This can be easily traced with the help of a multimeter.

How to know if a circuit board is working?

Thus, to know if all parts are working in sync with each other, you first need to unplug the device and the housing. Then switch it on and make sure that you do not touch any of the wirings.

Why is it important to test circuit boards?

It is because, with the help of a multimeter, comprehensive testing can be done without any damage. Moreover, all the components such as resistors, capacitors, and transistors can be checked without removing them physically from the board.

Is a multimeter analog or digital?

Multimeter today come in two variants, i.e., one is analog and the other digital. However, when it comes to test a circuit board with a multimeter, there are many discrepancies. Not many people know this, but before using a multimeter for finding faults in a circuit, it is necessary to have a little knowledge about electrical types of equipment.

Can you single out a faulty circuit board?

In this way, you can single out all the faulty components on the board. Always remember that you have to proceed systematically for all things to work out. From the first instance, when the incorrect voltage is found to check the preceding component’s output pins, every step has to be followed very keenly.

Why is PCB troubleshooting important?

PCB troubleshooting is a delicate process not only because the boards themselves are small in scale but because each of the individual components that comprises it is also sensitive. Repair techs must approach PCB maintenance with a keen eye for detail and mind for careful handling.

What is integrated circuit testing?

Integrated circuit testing — A final stage of PCB troubleshooting involves testing integrated circuits (ICs). An oscilloscope also comes in handy here. Unfortunately, it can be difficult to test ICs, depending on how many are present on a PCB or the nature of the circuit itself. The best approach is to identify a known good circuit and test all ICs against it to recognize problematic ones.

Why is it important to follow the four steps?

Following these four steps helps ensure techs give complete and thorough attention to each circuit board during troubleshooting. The methodical nature of this approach also allows repair techs to assess all the common causes of PCB failure so they don’t overlook issues.

What is the purpose of a PCB component test?

Component testing — Delving deeper into the PCB’s many components, you can test the integrity of batteries, capacitors, resistors, inductors, diodes, switches, and transistors. Use a multimeter to compare values to factory standards to spot discrepancies. Often, it’s these individual components that fail and eventually lead to larger failures of the entire PCB.

How to spot a board malfunction?

Visual inspections — You can see a lot through a visual inspection. Burned or eroded components are the easiest to spot, which signal overheating issues or chemical fluid leakage as reasons for malfunction. You can also identify missing components, indicating a flawed or defective board. Finally, clean away debris before probing the board deeper for issues .

What is a PCB?

Printed circuit boards (PCBs) are central to nearly every single electronic piece of equipment and machinery manufacturers use in factories today. A PCB’s chief job is to connect electrical components, relaying input signals to appropriate control actions. Because they’re so central to electromechanical operation, ...

Is every PCB failure the same?

Not every PCB failure is the same. Different problems affect boards in different ways — from short circuits to spotty operation, complete failure, and more. Here are some of the most common catalysts for PCB malfunction and failure: