Start by taping the edges of rupture of the tank with a hammer until they are aligned. Then weld any holes and weak spots closed. Replace the vent valve and run the compressor until the automatic shutoff turns the motor off. Watch the tank air pressure gauge as it rises to be sure the motor shuts off at the correct PSI.

Full Answer

How to fix compressor?

8 Air Conditioner Problems and How to Fix Them

- Is the filter dirty? No matter which type of air conditioner you have, a clogged air filter restricts airflow, decreasing efficiency and reducing the unit’s ability to cool the ...

- Is it too sunny inside? If your AC is in a window that gets direct sunlight in the heat of the day, it will have to work harder to ...

- Is warm air leaking in? ...

air conditioner problems and how to fix them/ar-AAWhoEg More items...

How to repair car AC compressor?

Oil balancing the a/c system:

- Measure the oil recovered from the system by recovery/recycling/recharging station.

- Drain and measure the oil left in the old compressor using a beaker.

- Drain the new compressor and refill it with the same amount of oil removed from the system and old compressor .

How to replace an AC compressor in your car?

Steps to Replace AC Compressor in Your Vehicle are:

- Remove the Accessories and Air Intake. As a first step, unbolt and remove the hoses or tubing in order to access the serpentine belt. ...

- Remove the Existing Compressor. Depending on your vehicle, the AC compressor might be in clear sight, or it could be buried under a layer of accessories and brackets ...

- Replace the O Ring Seals. ...

How to repair a Bostitch air compressor?

How to Repair a Bostitch Air Compressor

- Electrical and Mechanical Problems Are Interrelated. Electrical problems, such as a circuit breaker repeatedly tripping, aren't always caused by failure of electrical components, although they can be.

- Compressor Won't Switch On. ...

- Compressor Won't Maintain Desired Pressure. ...

- Water in the Air Lines. ...

Is it possible to repair a compressor?

Air compressor repair can be simple. The air compressor unloader valve is what makes the “psssssst” sound when the motor shuts off after reaching operating pressure. It's actually venting the residual pressure from the compressor head so the motor doesn't have to work as hard on the next startup.

How do you rebuild an air compressor motor?

1:022:35How to Rebuild an Air Compressor Pump - YouTubeYouTubeStart of suggested clipEnd of suggested clipThe piston out of the cylinder sleeve remove the Torx screw from the top of the piston remove. TheMoreThe piston out of the cylinder sleeve remove the Torx screw from the top of the piston remove. The piston cap and compression ring place the new compression ring on the top of the piston reinstall.

How do I know if my air compressor motor is bad?

Common Problems of Air CompressorCompressor Failure. An air compressor failing to start is one of the most basic problems you may encounter when operating the machine. ... Bogged Down Issues. ... Air Leaks. ... Pressure and Flow Problems. ... Uncharacteristic Noise and Vibrations. ... Oil Problems. ... Extremely Hot Emissions.

Why would an air compressor stop working?

An air compressor problem could stem from one of many issues, such as an air leak, an oil leak or a broken part. In some cases, you might have insufficient pressurization or air flow. In other cases, the compressor might fail to start up or stop running as prompted.

Can an air compressor be rebuilt?

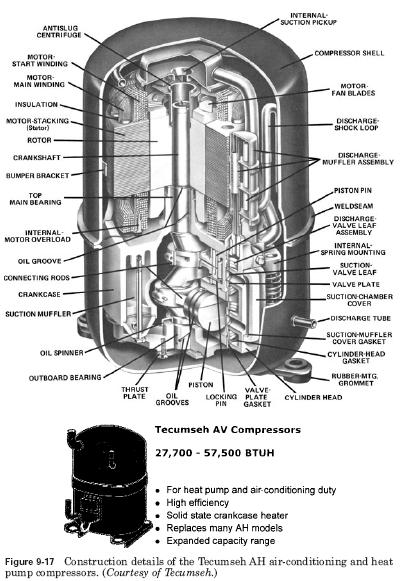

No, it cannot be rebuilt in the field when servicing a central air conditioning system. Defective motor compressors are replaced in the field with new or reconditioned units. The malfunctioning motor compressor is sent back to the factory to be reconditioned, then sold as a reconditioned unit.

What is a compressor overhaul?

A compressor overhaul usually involves an inspection and replacement of worn parts within your refrigeration compressor. We'll assess items such as: pistons, piston liners, con rods and bearings. Any part where friction is applied during the continued operation of the compressor.

What is the most common cause of air compressor failure?

The biggest cause of compressor burnout is overheating, which can occur when there is too much humid air trapped in the work area, especially on compressors with obstructed vents.

What is the most common cause of compressor failure?

Overheating is a common cause of compressor failure, and there are many factors at play. If direct sunlight falls on your outdoor unit and there is inadequate ventilation around it, it makes your unit's compressor overheated. High voltages can also damage the motor causing the compressor to overheat.

How do you test a compressor motor?

Here is how to check the compressor motor if you suspect it has failed;Disconnect power.Remove the top of the outdoor condensing unit.Unplug the 3-prong plug on the compressor.Set your multimeter to ohms.Measure and record the resistance (ohms) measurement of each winding.

What to do when compressor is not working?

Troubleshooting AC Compressor ProblemsCheck for tripped breakers. Find the breaker for the air conditioner in your service panel. ... Test the thermostat. Make sure the thermostat is set correctly and has fresh batteries. ... Listen for buzzing. ... Listen for clicking.

How do you troubleshoot a compressor?

6 Simple Steps to Troubleshooting a Compressor. ... Measure the Suction and Discharge Pressures. ... Check the Discharge Line Temperature. ... Record Temperatures in the Refrigerated Space. ... Perform a Compressor Valve Test. ... Checking for Compressor Electrical Motor Faults. ... Refrigerant System Problems.

How do you fix an air compressor that won't turn on?

If the compressor won't start with air in tank, replace the check valve. If the compressor won't start with an empty air tank, replace the pressure switch if it isn't activating the pump motor. Replace the pump motor if it doesn't start when activated by the pressure switch.

How do you disassemble a compressor?

0:015:19AC compressor take apart How it Works tear down air conditionerYouTubeStart of suggested clipEnd of suggested clipBut then there was a snap ring and then this is where your main bearing is pulling off this too itMoreBut then there was a snap ring and then this is where your main bearing is pulling off this too it doesn't come off yet.

How do you remove pistons from an air compressor?

2:2817:30Porter Cable Air Compressor Cylinder and Piston Rebuild - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo on the back there's a nut that goes on top of the stud. It's just holding a little clip in place.MoreSo on the back there's a nut that goes on top of the stud. It's just holding a little clip in place. So I just pull that off.

How do you change a piston on an air compressor?

3:329:08How to Replace a Piston and Cylinder Kit in a Campbell Hausfeld Oilless ...YouTubeStart of suggested clipEnd of suggested clipNext I'll pull the cylinder sleeve away from the piston that'll give us a little more play withinMoreNext I'll pull the cylinder sleeve away from the piston that'll give us a little more play within the piston. And then I'll tap the end of the eccentric shaft to pull the connecting rod. Away.

How do you change an air compressor head?

3:548:13How to Replace the Cylinder Head on an Air Compressor - YouTubeYouTubeStart of suggested clipEnd of suggested clipThe next step is to remove the head. Bolts. With the head bolts removed now i can remove theMoreThe next step is to remove the head. Bolts. With the head bolts removed now i can remove the cylinder head from the output tube and the tube seal.

How to Repair an Air Compressor

Below are some steps or procedures in how to repair an air compressor properly:

Frequently Asked Questions

A. Air Compressor serves as one of the important components in a pneumatic system. It helps in providing power to various types of equipment. When there’s a leak or damaged component, it can affect its performance. If you notice any abnormal signs indicating malfunction, then a proper fix is required.

Tools Needed For Air Compressor Switch Repair

Below are the tools with their description that you need and why and where you need them to fix your compressor.

How To Do An Air Compressor Pressure Switch Repair Yourself?

Below are simple and easy steps which you can follow to do an air compressor repair by yourself.

Air Compressor Repair FAQs

Ans: An air compressor unloader valve is a small, mostly brass-colored part that is located with the compressor pressure switch. Its main function is to vent out the trapped tank air in the compressor to reduce the load on the piston so the motor can start again. It usually sizes up 4″ to 5″ in length/width.

How to turn on a compressor?

We offer these tips regarding power and wiring that might affect your machine’s ability to turn on: 1 Always plug your compressor directly into an outlet, never a power strip. 2 Use three-prong extension cords that are less than 25 feet long to reduce resistance. They should also be at least 10 gauge. 3 Check to see if the compressor has tripped your circuit breaker. Repeated circuit breaker issues could be a problem with the air compressor wiring, an electrical circuit of insufficient amperage, or your electrical panel. If other machinery making the same electrical demands doesn’t trip your breaker, the problem is probably with the compressor. 4 Check to see that rodents or wear and tear haven’t frayed any wiring. 5 Make sure the contact is good between the power switch and internal circuitry. Sometimes switches need tightening due to vibration, and old switches may need replacement.

Why won't my air compressor stop running?

If you have a compressor that won’t stop running, it’s likely due to one of two causes. The pressure relief valve may be faulty. This makes the tank too highly pressurized and dangerous to use. Disconnect the air compressor from its power source and have it professionally serviced.

Why does my air compressor have a repeating circuit breaker?

Repeated circuit breaker issues could be a problem with the air compressor wiring, an electrical circuit of insufficient amperage, or your electrical panel. If other machinery making the same electrical demands doesn’t trip your breaker, the problem is probably with the compressor. Check to see that rodents or wear and tear haven’t frayed any ...

What happens when an air compressor goes bad?

When something goes wrong with your air compressor, it can result in lost work time and profitability. Here’s a look at the most common air compressor problems and some fixes you can try yourself to get up and running again.

What to do if your gauge drops?

If the gauge drops, you have an air leak. Disconnect the hose after performing the steps above . If the gauge stops dropping, you know the hose is the leaky element. Just like checking for a leak with a vehicle tire, you can apply liquid soap around connections and couplings to see if bubbles appear.

Why is my oil reservoir milky?

Oil in reservoir has a milky appearance: air intake needs to be less humid to reduce air in the oil. Compressor vibrating too much: tighten mounting bolts, and make sure the surface is level. Belts wearing out too quickly: adjust the tension up or down accordingly.