- Clean the surface to be repaired to remove all grease, dirt, and contamination.

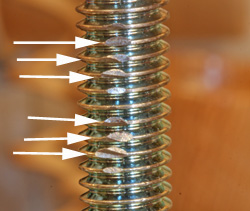

- Roughen the damaged female threads to help create a surface to which the epoxy will bond. ...

- Apply a coating of release agent to the fastener male threads to help prevent the epoxy compound from bonding to those threads during the curing process.

- Following the instructions included with the thread repair kit, dispense both parts of the epoxy compound and mix thoroughly.

- Again, following the instructions included with the thread repair kit, apply epoxy material to both female and male parts making sure that that the threads of both parts are completely ...

- Insert the coated male fastener into the female thread using a twisting motion. Center the fastener in the hole, and remove excess material. ...

- Following the instructions in the kit, allow the epoxy compound to cure before removing the fastener.

- Once the compound is cured, and the fastener is removed, the repaired threads are ready for use.

How do you repair how do you repair stripped threads?

Automotive, Tool Guides

- Never Use Standard Sockets on a Impact Gun or Air Wrench. You should always use thick walled sockets when using any type of air or electric wrench. ...

- Use penetrating oil and clean exposed threads. ...

- Try tightening the nut or bolt to break it free. ...

How to restart threads?

How to Restart SMS Executive Threads Cloud User Sync from Registry ConfigMgr Configuration Manager? Do you know how to restart the SMS execute threads like “SMS_DMP_DOWNLOADER” and “SMS_CLOUD_USERSYNC” of SCCM / ConfigMgr Current Branch (CB)?Yes, this can be done via the SCCM Service manager.

How to remove studs without damaging the threads?

How to Remove a Broken Bolt and Studs

- Bolt or Stud Extractor for the Protruding Broken Stud/Bolt. ...

- Fluted Extractor for When It Breaks Too Close to Grip. ...

- Hammering Can Break up Rust. ...

- Welding. ...

- Drill and Tap. ...

- Heli-Coil. ...

- Heat. ...

- A Final Option for Small Bolts/Screws. ...

How to start a thread again?

The start thread performs the following tasks:

- It stats a new thread

- The thread moves from New State to Runnable state.

- When the thread gets a chance to execute, its target run () method will run.

Can you fix damaged threads?

Damaged threads on a screw or bolt can often be fixed by running a die over it, and if a thread's damage is minimal, it may be possible to reform the threads by running a nut up and down them, though that runs the risk of the nut fusing to the thread (galling).

What is used to repair damaged threads?

A cutting die cuts new threads, whereas a rethreading die is like a thread chaser to fix slightly damaged or dirty threads. Some cutting dies are split with a set screw to adjust the size of the cut for minor variations on diameter. Most hobbyist-type kits use solid dies.

How do you fix a ruined thread?

The thread repairDrill thread. First you drill the damaged thread with a twist drill. ... Cut thread. Now you can cut the new thread with the single-cut tap. ... Insert thread insert. Put the thread insert on the fitting-tool or directly into the hole (see second picture below). ... Break pin.

How do you Rethread stripped threads?

1:202:46How to Fix Stripped Bolt Hole Threads on Your Car - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo basically we get our long extension stick it in the hall with a threading tool. And start to turnMoreSo basically we get our long extension stick it in the hall with a threading tool. And start to turn the ratchet. To eat the threads. In. And when it starts to get snug.

Will Loctite work on stripped threads?

Loctite® Form-A-Thread® It restores worn, stripped or damaged threads and eliminates future corrosion, galling, seizing, and rust, and allows up to 128 ft. lbs. of torque between -65°F to 300°F. It permanently repairs stripped threads and fasteners in five minutes (up to SAE Grade 5 English and 8.8 metric).

How do you make JB Weld threads?

0:423:19does JB Weld “really” fix aluminum threads - YouTubeYouTubeStart of suggested clipEnd of suggested clipWeld. Make sure you get all the way down in there thread the bolt. In. Place now let it sit for 24.MoreWeld. Make sure you get all the way down in there thread the bolt. In. Place now let it sit for 24.

How do you repair steel threads?

0:0916:18How to repair stripped threads in aluminium or steel - YouTubeYouTubeStart of suggested clipEnd of suggested clipIf you have a damaged ice to it to the bolt like this you will need to replace it in someMoreIf you have a damaged ice to it to the bolt like this you will need to replace it in some circumstances when you get a stripped hole. You can actually drill the hole out larger.

What causes thread damage?

Thread damage can occur as the result of one or more of these factors... Use of incorrect bolt torque specifications. Cross-threading or improper installation of fastener. Use of incorrect fastener size or thread pitch.

How do you fix a thread without a tap?

0:442:11Easily repair a cross threaded hole without a tap! - YouTubeYouTubeStart of suggested clipEnd of suggested clipSlide to the bolt will make our act as a cutter when it gives it a relief for the material to getMoreSlide to the bolt will make our act as a cutter when it gives it a relief for the material to get into the slide. Once you run that through the thread your bolts for reading with its.

What is a thread chaser tool?

Definition of thread chaser : a multiple point tool used typically as one of a set of four in a die head for cutting a screw thread.

How do you use thread repair inserts?

3:255:17How to Use & Install Helicoil Thread Inserts | Fasteners 101 - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd you have to apply pressure as you do it it should be down just about 2 turns from the top. AndMoreAnd you have to apply pressure as you do it it should be down just about 2 turns from the top. And that's what it is ok. So there it is. And once they're in there. It's hard to back it off.

What is used to repair damaged external threads of a bolt?

Use a rethreading tap to restore threads on nuts or threaded engine component holes. Don't try to rethread the entire bolt, hole or nut in one operation. Insert the rethreading tap or die and rotate a few turns, then back it off a full turn.

What is a thread chaser tool?

Definition of thread chaser : a multiple point tool used typically as one of a set of four in a die head for cutting a screw thread.

What is thread repair insert?

Thread-repair inserts come in a variety of materials and in a myriad of designs from domestic and overseas manufacturers. Timed thread body inserts, wire coil inserts and keyed inserted make up the three major families of thread inserts you’ll likely encounter.

How to repair M10x1.25 thread?

For an M10x1.25 thread repair with a Keensert, a 12.5mm drill would be used for the M14x1.5 tap. The M14x1.5 tap would have a major diameter up to 14.4mm (an M10 repair with an S.T.I. tap would only have a 11.787mm major diameter). That’s a much bigger hole which can be beneficial in some application where severe corrosion is prevalent in the original threads. The Keensert would then be threaded into the drilled, tapped and cleaned hole with the Keensert installation tool. Thread locking compounds can be used due to its solid body design. Once set in position, the installation tool is then used to drive in the four key stakes into position. This provides the ultimate mechanical locking of the insert in place. Hence, this design sports exceptional resistance to vibration. Now the downside. The massive outside diameter of the insert makes it unviable in applications where the material around the original threaded hole is limited, such as any “thin-wall” castings. Second, the cost for a standard-steel Keensert is about 4.5 times that of a HeliCoil and more than double the cost of a TIME-SERT. If you want a stainless-steel Keensert, the cost goes through the roof being about 25 times the cost of a HeliCoil.

How hard is it to drill a stripped hole?

How easy or how hard usually depends on the access to the stripped hole. If you can take off the entire header and get enough access to fit a cordless drill in the area to drill out the hole before tapping, it pretty easy. I;'m guessing it would probably be an M8x1.25 thread. Compare the size and thread on one of the good bolts to a know M8x1.25 bolt to confirm.

Can you have a thread failure in the same hole again?

Done right, you’ll never have a thread failure in the same hole again.

Is stripper thread more common than ever?

As a result, it’s no surprise that strippers are more common than ever before. Since most of the threads on today’s vehicles are made of materials with just one-third to one-half the hardness of grey cast iron, it’s no wonder that more threaded holes experience thread damage than ever before.

Can Keensert be threaded?

That’s a much bigger hole which can be beneficial in some application where severe corrosion is prevalent in the original threads. The Keensert would then be threaded into the drilled, tapped and cleaned hole with the Keensert installation tool. Thread locking compounds can be used due to its solid body design.

Did the steel I.D. thread chew it?

Yes the steel I.D. thread probably chewed it like butter.

Why does my thread get damaged?

Typically, thread damage on a a male thread (a screw or a bolt for instance) is caused when incorrect bolt torque is used, when thread fretting occurs as a result of prolonged vibration during machining applications, or when the threads become worn after extended use over time.

Does a gage edge fit into the remaining threads?

The gage edge will fit perfectly into the remaining threads when you have the correct gage blade selected (there will be no gaps between the gage's teeth and the edge of the screw's or bolt's remaining threads).

How to repair a stripped thread?

Similarly, when threads are stripped out of a hole, there are a number of approaches one can take to repair them. Drilling out the hole and tapping it with a larger diameter thread is one option, provided there is room for a larger fastener. When creating a new, larger tapped hole isn't optimal or possible, use of a thread repair kit is recommended.

Why does my thread get damaged?

Typically, thread damage is caused when a tap or fastener breaks in a hole, when a fastener is installed incorrectly , when incorrect bolt torque is used, or when thread fretting occurs as a result of extended or extreme vibration ...

What is a thread repair kit?

They may also be used to create strong threads in soft materials including aluminum. Thread repair kits consist of a tapping tool, an insertion tool, and thread inserts. A tap wrench and drill will also be necessary when using a thread repair kit. The drill bit is not always included in the kit. The most popular type of thread insert used in ...

What to do when you have a tapped hole?

When creating a new, larger tapped hole isn't optimal or possible, use of a thread repair kit is recommended. Thread repair kits allow you to remove the damaged threads that are stuck in a hole and replace them with new threads of the same diameter.

Why use helical thread insert?

An installed helical threaded insert can provide a more secure threaded connecting point and overall stronger threads.

How to break off a tang?

Break off the tang where the thread insert wire returns across the hole (A hex tool can be inserted through the new thread to rest against the tang and it typically will snap off easily with the light tap of a hammer).

What is the tension between the insert and the walls of the hole?

The tension between the insert and the walls of the hole helps to keep the insert in place and keep it from unthreading. The helix has a small return at one end that engages with the kit's included insertion tool, allowing the insert to be screwed into the hole.

What causes threads to be damaged?

There are various causes that can lead to the destruction of threads, for instance corrosion, wear or a too high tightening torque. In this article we will explain how to fix the damaged thread. Before you can start repairing the damaged thread, you will need the following tools: drilling machine. twist drill.

How to turn thread insert?

Turn the thread insert under slight pressure in the thread direction (see third picture below).

Can you use cutting oil on hand?

If you have cutting oil on hand, you can use it well here.

What is a thread repair insert?

Thread repair inserts, allow for threads to be repaired, recreated, or reinforced to the original bolt size and pitch. Solid inserts which are often made of stainless steel or carbon steel, can not only be used to repair damaged threads but also to reinforce soft base metals like aluminum to be able to take a much higher torque.

Can you fix threads?

There are many not so ideal ways of fixing damaged threads by way of oversizing and cross threading; but what a lot of people don’t know is that there are many engineered solutions to properly fixing damaged threads. Even more problematic is that most people are only aware of coil based repair kits (like helicoil or permacoil).

Do self tapping inserts require a pretapped hole?

Self tapping (gardsert/seal-lock/ensat) Installation: The easiest method of all, these types of inserts do not require a pretapped hole, as they create their own threads as they are installed. They also do not require special installation tools and utilize a normal nut and bolt for installation.