A common method of repair is to send the broken piece to a high-quality chrome plating shop for repair. They will copper plate the piece and use the copper as a base to solder the pieces back together, often followed by typical chrome plating. This is the smart way to repair a die-cast piece if chrome plating is involved.

What's the best way to restore cast aluminum?

Soaking a pan or small furniture items in cream of tartar and water before scrubbing them can make it easier to remove any residue. You can try to scrub cast aluminum furniture with a soft toothbrush or a fine scrub pad without soaking it first. ... Avoid using any metal utensils or steel wool on cast aluminum items. ...

What is the best way to clean cast aluminum?

- Use a clean cloth or soft scrubbing pad to rub the solution into the furniture.

- Continue buffing the surface until the aluminum begins to brighten up.

- Rinse the furniture clean with a hose.

- Dry the furniture with a clean cloth.

How to repair cast aluminum without welding?

Step-by-Step Guide for Brazing Aluminum

- Preparation. Before you commence preparing the aluminum surface, followed by brazing, you must wear protective clothing.

- Preparing the Aluminum Surface. Brazing works to the bond aluminum surface like welding when performed on clean areas. ...

- Brazing the Aluminum. Pick your filler rod and dip it into all-purpose flux. ...

How to make cast aluminum look new?

- Best Ways to Clean Cast Aluminum How to Clean Cast Aluminum with Lemon Juice or Vinegar DIY Aluminum Wheel Cleaner Using Oven Cleaner to Wash Aluminum Ways to Clean Cast ...

- What are the Side Effects of Commercial Aluminum Cleaners?

- How to Maintain Cast Aluminum Pans

Can you repair die cast?

Metal glue works well for diecast repairs because the adhesive specifically works on metal surfaces. As metal glue is typically gray and resembles the natural color of the metal, so use the glue only on diecast pieces without any bright colors or high levels of decoration.

Can die cast metal be soldered?

Depends on the die-cast metal grade and type, but assuming Mazak, or Zamak, (zamac), then, yes, it will solder with ordinary tin lead solder, and an acid flux. But, most people have really extreme difficulty getting it to work, because not enough heat is used, and not the right type of flux.

Can Die Cast be welded?

Die cast parts made from the alloy AlSi9MgMn (Silafont-36) are particularly well suited for welding, both the standard MIG and TIG methods (see Gas-shielded welding processes) and laser beam welding.

How do I fix my diecast car?

2:495:40How To Fix Broken Diecast Cars | Heavy MeTal Models - YouTubeYouTubeStart of suggested clipEnd of suggested clipUse your applicator. And a drop of adhesive. And place the piece onto the car you can make smallMoreUse your applicator. And a drop of adhesive. And place the piece onto the car you can make small adjustments then leave the piece to drive. Give it time 15 minutes should be plenty.

How do you solder a die cast?

2:016:22How to Solder Hot Wheels ZAMAC Metal and Repair a Vintage Redline ...YouTubeStart of suggested clipEnd of suggested clipAnd then apply a tin soldering iron as the flux begins to boil off I'll come in with the solderingMoreAnd then apply a tin soldering iron as the flux begins to boil off I'll come in with the soldering wire add a little bit more. If all goes well the solder wets the surface. And sticks to the die cast.

Can you braze die cast metal?

While zinc die cast can be difficult to solder due to its low melting temperature of 786°F, Super Alloy 1 has a working temperature of 350°F, making it the ideal solution for soldering or brazing zinc die cast parts–with any torch: propane, MAPP gas, butane, acetylene, oxyacetylene, or even a heat gun.

How do you fix cast aluminum without welding?

Using a propane torch and some aluminum brazing rods is a quick way to bonding aluminum without using a welder. It makes for a very strong bond and with a little practice can be done quickly with great looking results.

Can cast aluminum be repaired?

You can actually use Aluminum braze to repair cracks, holes, leaks, rivets, broken ears, threads or fabricate aluminum, cast aluminum, and cast iron quickly, easily, and stronger than new. It's not hard at all. Many aluminum alloys can be brazed.

How strong is JB Weld on cast aluminum?

For a reliable aluminum epoxy that can handle medium- to heavy-duty jobs, the J-B Weld KwikWeld epoxy has a 5,020 PSI rating and withstands temperatures of over 500 degrees Fahrenheit, making it an ideal option for cars, RVs, and boats.

How do you restore diecast metal?

3:305:34Quick Tip: An Easy Way to Remove Oxidation from Diecast CarsYouTubeStart of suggested clipEnd of suggested clipI found toothpastes would be the best option as it's more abrasive than rubbing compound. But lessMoreI found toothpastes would be the best option as it's more abrasive than rubbing compound. But less abrasive than a wire brush.

How do you fix white cast on metal?

0:041:38Zinc Die Cast or Pot Metal Tips to Repair Broken Pieces ... - YouTubeYouTubeStart of suggested clipEnd of suggested clipSimply heat the end of an old butter knife and shape the Souper all a one just the way you. Wanted.MoreSimply heat the end of an old butter knife and shape the Souper all a one just the way you. Wanted. Sometimes you may have high or low areas after soldering.

How do I reset my diecast models?

0:281:05:14How to restore Diecast Cars - YouTubeYouTubeStart of suggested clipEnd of suggested clipStore. So an assortment of flat files. Around rat tail file would be handy. And then there's aMoreStore. So an assortment of flat files. Around rat tail file would be handy. And then there's a triangular file this one works real good to get into little little spots to make angles.

How do you weld diecast?

3:0310:05How to Solder and Repair Die-cast Cars. (Redline Restoration - YouTubeYouTubeStart of suggested clipEnd of suggested clipNext I'll apply a little bit of flux to a toothpick. This flux will help the solder flow into andMoreNext I'll apply a little bit of flux to a toothpick. This flux will help the solder flow into and around the broken diecast.

Can you weld zinc die cast?

0:334:24Pot Metal and Zinc Die Cast Repairs Made Easy With Super Alloy 1 Multi ...YouTubeStart of suggested clipEnd of suggested clipBuilding up missing sections is simple if you have the right tool the young lady building back thisMoreBuilding up missing sections is simple if you have the right tool the young lady building back this headlight ring is never used super alloy one before and made this repair with ease.

Can you solder zinc alloy?

Soldering with zinc-based alloys is achieved by applying zinc alloy in either a stick or powder form. The area being repaired needs to be preheated to approximately 600 F (315 C). The most commonly used solders for repair (Figure 55) include zinc-tin-lead, zinc-cadmium, and zinc-tin-copper alloys.

Can Zamak be welded?

This oxide layer is very hard and has a melting temperature of over 2000 °C, which is more than three times that of aluminum. So it must be removed to allow welding, but it is difficult to do.

How to glue metal to diecast?

Apply a small amount of the metal glue to one side of the diecast and press that side against the unglued portion. Hold the metal together until the glue begins curing and is strong enough that it holds together on its own. Advertisement.

What is diecast metal made of?

The fabrication process uses lead metal, often mixed with another type of metal like aluminum or zinc. The liquid metal pours into a mold, creating the shape of the item.

Can you use metal glue on diecast?

As metal glue is typically gray and resembles the natural color of the metal, so use the glue only on diecast pieces without any bright colors or high levels of decoration.

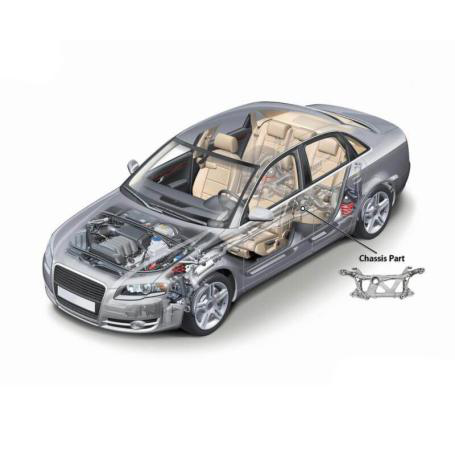

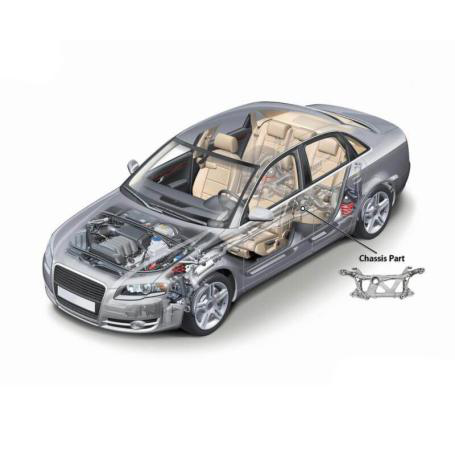

What is die casting?

Die casting is a process that can produce geometrically complex metal parts. lots of problems will occur when you don’t pay attention to it during production. A high level of technical expertise and attention to detail is required to prevent small errors from causing huge losses to the company in the mass production of new parts.

What are the problems with castings?

1. The casting structure is unreasonable, the shrinkage is blocked and the casting fillet is too small. #N#2. The core pulling and ejection device skew in the work, uneven force.#N# 3. Mold temperature is low.#N# 4. Opening and core pulling time is too late.#N# 5. The use of alloy improper or harmful impurities is too high so that the plasticity of the alloy decreased. Zinc alloy, lead, tin, cadmium, iron, and high aluminum alloy: zinc, copper and iron, copper alloy high silicon high magnesium alloy: aluminum, silicon, high iron

How to keep crucibles from overheating?

1. The alloy should not overheat, avoid alloy long time insulation.#N#2. Increase the mold temperature, reduce the pouring temperature. #N#3. Strictly control the chemical composition of the alloy.#N#4. Keep the coating of the crucible intact and well.

How to refine aluminum alloy?

The aluminum alloy contains titanium, manganese, iron and other components, should not make segregation and keep clean, with dry refining agent refining, but in the aluminum alloy containing magnesium, should pay attention to compensation.#N#3. An aluminum alloy containing copper, iron content for a long time, should reduce the silicon content to below 10.5%, appropriately raise the pouring temperature, so that the silicon precipitation.

How to improve the fluidity of an alloy?

1.Improve the fluidity of alloy:#N#a.Adopt the correct smelting process , excluding gas and non-metallic inclusions.#N#b.Increase the pouring temperature and die temperature of the alloy.#N#c.Increasing the injection velocity.#N#d.Adding nitrogen to raise the effective pressure.#N#e.Adopting quantitative pouring.#N#f.Improve the casting structure and adjust the wall thickness properly.

What are the metals that are used in alloys?

The use of alloy improper or harmful impurities is too high so that the plasticity of the alloy decreased. Zinc alloy, lead, tin, cadmium, iron, and high aluminum alloy: zinc, copper and iron, copper alloy high silicon high magnesium alloy: aluminum, silicon, high iron.

What are the features of a casting?

Features: the alloy matrix on the casting is broken or broken to form a slit with a fine wire. There are two kinds of penetrating and non-penetrating, which have a trend of development. Cracks can be divided into two kinds of cold cracks and hot cracks.

Causes of oxidation of die-cast aluminum

On the surface, it looks like a white velvet, just like everyday things are moldy, but after wiping off, small gray-black spots appear underneath. This is a phenomenon that occurs when aluminum is oxidized. Next, we analyze the reasons for the oxidation of die-cast aluminum:

Commonly used methods to solve die-cast aluminum oxidation

1. Generally, the finished aluminum parts must be sealed and packaged to prevent the substances in the air from affecting storage and oxidation. If it is a cleaned aluminum part, it must be dried. It must be thoroughly dried when packed in a bag.