To repair a lifted pad:

- Clean the area with either a swab saturated with a solvent cleaner like isopropyl alcohol (IPA) or a CircuitWorks Flux Remover Pen.

- Apply the mixed conductive epoxy under the pad with the supplied plastic pick.

- Press down the pad.

- Allow the epoxy to fully cure before soldering to the pad.

How to repair a damaged printed circuit board pad?

How to Repair Damaged Printed Circuit Board Pads Step 1: Tidy Up the Damaged Track 1:. Remove as little of the damage as possible to get back to a sound track. Cutting... Step 2: Tidy Up the Damaged Track 2:. Once the damaged track is removed it should look something like this. Step 3: Exposing the ...

How do I fix a damaged pad on my keyboard?

· Cleaning the damaged pad: Thoroughly clean the damaged area with isopropyl alcohol, and follow up by drying the area with a lint-free cloth or compressed/canned air. · Removing the damaged pad: Use an X-Acto knife to carefully cut away the damaged pad.

What happens if you lift the pad on a circuit board?

However, if you have lifted pads, the pins may not be able to make that connection cleanly and the component will fail. Where am I Likely to See Pad Lifting on a Circuit Board?

How to fix a broken solder pad on a circuit board?

For the pad that lifted, stick the component through the hole and solder your wire to the component leg. Glue the pad back to the circuit board with a strong epoxy. Bend the component lead to replace the track where the solder pad/trace that lifted should be and solder it directly to the track that still has a connection to the board.

How do you fix a lifted PCB pad?

Repairing a Lifted Pad It may not be pretty, but a lifted pad can usually be repaired. The simplest repair is to fold the lead over to a still-attached copper trace and solder it as shown to the left. If your board has a solder-mask, you will need to carefully scrape off enough to expose the bare copper.

How do you fix the pad on a circuit board?

1:4710:17How To Repair Damaged /Missing PCB Pads - INVISIBLE Fix #solderingYouTubeStart of suggested clipEnd of suggested clipScreen i'll just put a little line across there that helps it to sort of be removed. Easy. Same withMoreScreen i'll just put a little line across there that helps it to sort of be removed. Easy. Same with this one. And then i can just get on what i do just get under the corner of the pad.

What do you do when a soldering pad comes off?

3:056:02How to Bypass Missing & Broken Solder Pads - YouTubeYouTubeStart of suggested clipEnd of suggested clipUse my knife to scrape away the silk. Screen. Clean away any debris with ipa. And a cotton swab. AddMoreUse my knife to scrape away the silk. Screen. Clean away any debris with ipa. And a cotton swab. Add some flux. And then a bit of solder already on the tip of my iron. And then clean again to make

Why do solder pads lift?

Pad lifting on printed circuit boards during the assembly process is typically caused by a combination of a thermal and physical issue. The adhesion of the copper foil decreases as the surface heats up, so directly after soldering the copper adhesion can be low.

How do you fix a lifted trace?

Step One: Locate the lifted trace, then identify the pads or joints on each end. Step Two: Clean the area with rubbing alcohol to remove any dirt or grease. Step Three: Cut any loose pieces of the trace from the board. Be extremely careful not to damage any other part of the board while doing this.

Can you reattach a solder pad?

Soldering the new pad/trace to the conductor: Use Kapton tape to place and hold the replacement pad. Use the appropriate solder alloy to make a lap joint. Clamping and curing: Clamp the new pad/trace in place and cure. Once cured, remove the clamp and clean the pad/trace with isopropyl alcohol.

How do you repair a soldering pad?

5:5711:54How To Repair Damaged / Missing PCB Pads || 4 Great MethodsYouTubeStart of suggested clipEnd of suggested clipSo basically what you do just hold the outside edges with your tweezers. And just add the first sortMoreSo basically what you do just hold the outside edges with your tweezers. And just add the first sort of bit of solder. And that will basically keep that pad in place.

Can soldering damage PCB?

Using soldering with recommended temperature won't damage the board.

How do you fix a loose circuit board connection?

1:382:54How To Fix Bad Solder Joint On Circuit Board (Using ... - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd use a solder sucker. And there you see that the old solder has been sucked up.MoreAnd use a solder sucker. And there you see that the old solder has been sucked up.

How many times can you Desolder a PCB?

If you have a desoldering station, perhaps 5 to 10 times with an experienced operator. With large parts or ground plane attachment, a preheater for the PCB; along with a proper desoldering station; reduces the risk of board damage. Using a desoldering station requires proper technique and practice.

What is lifted pad?

A lifted pad on a printed circuit board is a pad that detached from the surface of a PCB. This results in an improper connection to the lead or component causing the PCB board to malfunction or not work. This defect is usually found on single-side PCBs that use a thin copper layer with no through-hole plating.

How do you solder a pad?

0:433:28How to Solder - Fill the pads with solder - YouTubeYouTubeStart of suggested clipEnd of suggested clipAfter you clean the soldering iron add a tiny bit of solder to the tip. So you can see where the hotMoreAfter you clean the soldering iron add a tiny bit of solder to the tip. So you can see where the hot part is touch the pad. And when the pad is hot enough add the solder to the pad.

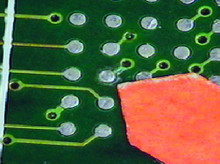

What is a pad on a circuit board?

A pad is the exposed region of metal on a circuit board that the component lead is soldered to. Multiple pads in conjunction are used to generate the component footprint or land pattern on the PCB. The two types of pads available are through-hole and surface mount pads.

How do you solder small pads?

0:145:40How To Solder to Small Pads - Specifically the R-XSR Receiver Un ...YouTubeStart of suggested clipEnd of suggested clipAnd it will heat up that pad at the exact moment. And allow that solder to stick in place. So I'mMoreAnd it will heat up that pad at the exact moment. And allow that solder to stick in place. So I'm gonna show you how I do that so I'm gonna hold it. There.

Step 1: Cleaning

Clean the damaged are with isopropyl alcohol and blow dry with canned or compressed air or damp dry with a lint free cloth.

Step 5: Clean

Clean the area using isopropyl alcohol and dry via compressed or canned air or a lint free cloth.

Step 6: Tin the Conductor

Using the correct type of solder alloy tin the conductor area in place where the new conductor will be attached

Step 7: Sise Up and Select the Right Circuit Frame

Select the new conductor from the circuit frame. Cut out with sharp small knife.

Step 10: Clamp and Cure

Hold the replacement pad/trace in place until cured. Remove the clamp. Clean with isopropyl alcohol and inspect. I also like to perform a quick electrical continuity check at this point. In some cases I even envelope the edges of the replacement pad/trace with solder mask or epoxy and cure so that it has extra mechanical strength.

How to solder a pad that lifted?

For the pad that lifted, stick the component through the hole and solder your wire to the component leg. Glue the pad back to the circuit board with a strong epoxy. Bend the component lead to replace the track where the solder pad/trace that lifted should be and solder it directly to the track that still has a connection to the board.

How to avoid pad lifting?

To avoid pad lifting on a printed circuit board, it’s important to take single-sided boards off the conveyor or out of pallets very carefully, and make sure your operators do not use large components as handles. In general, whenever you think there is a danger of pad lifting, handle those printed circuit boards with extra care.

How to replace a printed circuit board?

If you don’t want to trash the printed circuit board and start over with a new one, there are a number of things you can try. For example: 1 Find where the trace the pad lifted from starts and ends, then run wires to every disconnected point. For the pad that lifted, stick the component through the hole and solder your wire to the component leg. 2 Glue the pad back to the circuit board with a strong epoxy. 3 Bend the component lead to replace the track where the solder pad/trace that lifted should be and solder it directly to the track that still has a connection to the board. If the lead is too short, solder an extension onto the lead, then proceed.

Why do printed circuit boards lift?

What Causes Pad Lifting on Printed Circuit Boards? Most commonly with single-sided boards, after the wave soldering, the heating up of the surface can lower the adhesion of the copper, so any force you apply to the components may cause lifting.

Can you lift a pad on a single sided board?

You will most often see pad lifting on a single-sided board in the course of assembly. If you have plated-through hole boards, it is unlikely pad lifting will occur, although it is not impossible. Anytime you have the combination of extreme heat and serious physical handling, pad lifting is a possibility to consider.

Can you use epoxy with thermal resistance?

There is little you can do about the thermal element. You can try to use an epoxy with high thermal resistance, but it is inevitable that any prolonged, high degree of heat will reduce adhesion. Again, one solution is to use plated-through hole boards, which make it much harder for pads and components to come loose.

Can you change your PCB distributor?

If you are repeatedly getting printed circuit boards from your PCB distributor with lifted pads, or pads that lift with normal handling after you receive them — especially if you are experiencing lifted pad problems with plated-through hole boards — you should strongly consider changing your PCB distributor.

What to wear when handling PCBs?

These are issues to be concerned about: Wear safety glasses – Solder can splatter or leads can fly when trimmed, so wear safety glasses to protect your eyes anytime you are repairing a PCB.

How to repair a trace with a conductive pen?

If there is solder resist right up to the break, use a sharp blade to scrape away about a 1/16” portion of the resist.

What is solder wick?

Solder wick – Solder wick, desoldering wick, or just "wick" are all names for a copper braid that is used to absorb solder. It is generally coated with flux, so when heated, solder is melted, drawn up, and retained using a combination of wetting and capillary action.

How do solder suckers work?

Solder suckers – Solder suckers use a spring loaded vacuum to draw up melted solder. The solder needs to be melted by either with a soldering iron or hot air, like from a heat gun or rework station. Only small amounts of solder are drawn up at a time, or it often takes multiple attempts to remove a component.

Why does solder stick to hand lotion?

The solder may stick temporarily, but pop off when exposed to any kind of thermal or physical stress.

How to prevent ESD?

Wearing a grounded wrist strap and working on a grounded ESD-safe mat is the best way to prevent ESD. A wrist strap has a conductive surface that touches the skin, so can bleed off excess electrons. An ESD-safe mat works by a similar principal, so bleeds off a charge from anything on its surface.

How to get adhesive off of a label?

Lightly press the pen tip on the label until the tip saturates enough for solvent to start to flow. Rub saturated pen tip over the label area and allow it to soak through. Allow the saturated label to sit for at least 15-20 seconds, then rub area with pen tip until label material and adhesive is removed.