How to Fix Pitting in Metal Before Painting

- Clean. Wrap a sheet of 80-grit sandpaper around a sanding block and sand the pitted area aggressively. You can use a...

- Fill Pits. Mix the correct ratio of two-part auto body repair filler and hardener, as determined by the product...

- Finish. Sand the metal and hardened filler with a sanding block and 80-grit sandpaper, if...

How to fix pitted metal before painting?

How to Fix Pitting in Metal Before Painting 1 Clean. Wrap a sheet of 80-grit sandpaper around a sanding block and sand the pitted area aggressively. ... 2 Fill Pits. Mix the correct ratio of two-part auto body repair filler and hardener, as determined by the product instructions, on an old scrap of wood or metal, and blend ... 3 Finish. ...

How do you get rid of a pitted surface on metal?

Clean Wrap a sheet of 80-grit sandpaper around a sanding block and sand the pitted area aggressively. You can use a power sander instead of sanding by hand, but it might remove too much material and weaken the metal. If the metal item is very heavy, you can likely sand with a power sander.

How do you fix a small dent on a sheet metal airplane?

You can repair a small dent with a filler material. SuperFil is an ideal filler material because it does not shrink with time. Bondo filler tends to shrink after being applied. Apply the SuperFil with a squeegee, let it dry overnight, sand it smooth, and touch up the area with paint. Small cracks are a common problem on sheet metal airplanes.

How do you fill pitted metal with filler?

Fill Pits. Scrape up the blended filler on the edge of a plastic putty knife and spread it over the pitted metal. Drag the edge of the knife over the surface to remove the excess filler, leveling the pits to be even with the rest of the metal.

Can pitted metal be repaired?

Repairing pitted metal is similar to smoothing out imperfections on a wall, but the products are designed specifically to work with metal and inhibit rust. The chemicals used are hazardous, so use protective eyewear, gloves and a face mask when sanding and applying chemicals or paint to metal.

How do you get rid of pitting corrosion?

If a component is still structurally sound, pitting corrosion can be mechanically removed by grinding or polishing and the missing metal replaced by weld build-up. Care must be taken to prepare and undertake the welding process carefully, to avoid reducing the properties of the surrounding metal.

How do you fill pitted metal rust?

0:273:45Car Rust Repair -How to Fix Rust Pits in a Fender with Glazing ... - YouTubeYouTubeStart of suggested clipEnd of suggested clipThe fast stitch will dissolve the rust leaving with nice clean metal then spray some rustMoreThe fast stitch will dissolve the rust leaving with nice clean metal then spray some rust encapsulator on the area and sand it off the rust encapsulator will remain in the pits.

How do you keep pitting from rusting?

Pitting corrosion can be controlled by:Use of a coating that will prevent pitting on metal surfaces.Using more corrosion resistant materials.Ensuring that the fluids in contact with the material is washed away regularly.Use of cathodic protection.Avoiding stagnant zones.Inhibitor use / fluid chemistry control.More items...•

Can pitting corrosion be repaired?

Pitting Repairs: Welding Localized corrosion in the form of deep pits can be repaired by welding to restore the original profile; however, sufficient expertise and special tools are required.

Can you polish out pitting?

Rub lightly with 1,000-grit paper using a circular motion. Rub until all signs of pitting have disappeared. Wipe with damp cloth and then pat until dry. Rub lightly and briskly with 0000 fine steel wool until tiny scratches left by the 1,000-grit paper have disappeared.

How do you paint over pitted metal?

InstructionsRemove Loose Rust. Use the wire brush to slough away all of the loose rust and any paint. ... Sand the Rust. Sand the rusted metal to remove more of the rust and to smooth down the surface. ... Clean the Surface. ... Apply the Rust Converter. ... Paint the Metal.

Is there a filler for metal?

Permatex Liquid Metal Filler is an easy-to-use filler that can be drilled, filed, sanded and painted. It forms a long-lasting, metal-tough bond and works on metal, wood, and concrete.

How do you clean pitted steel?

If stainless steel is rusted or pitted:Clean the affected area. ... If cleaning does not remove the rust, then very carefully and lightly, with the grain of the stainless steel, use a fine-grain Emery Cloth or Green Scotch-Brite Scouring Pad to remove rust.More items...

Can you paint over pitted rust?

0:411:57Tech Talk - How to Stop Rust in Pitted Metal - Eastwood - YouTubeYouTubeStart of suggested clipEnd of suggested clipThis is now ready for epoxy primer bodywork urethane primer or anything you may want to do next.MoreThis is now ready for epoxy primer bodywork urethane primer or anything you may want to do next. Using this method of applying rust encapsulator platinum on any pitted areas of metal.

What causes metal pitting?

Most cases of pitting are believed to be caused by local cathodic sites in an otherwise normal surface. Apart from the localized loss of thickness, corrosion pits can also be harmful by acting as stress risers. Fatigue and stress corrosion cracking may initiate at the base of corrosion pits.

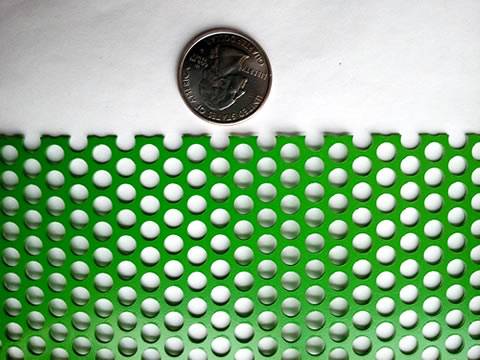

What does pitting look like?

1:313:22What does pitting look like? - YouTubeYouTubeStart of suggested clipEnd of suggested clipBut they basically look like little divots in the metal.MoreBut they basically look like little divots in the metal.

Can you paint over pitted rust?

0:411:57Tech Talk - How to Stop Rust in Pitted Metal - Eastwood - YouTubeYouTubeStart of suggested clipEnd of suggested clipThis is now ready for epoxy primer bodywork urethane primer or anything you may want to do next.MoreThis is now ready for epoxy primer bodywork urethane primer or anything you may want to do next. Using this method of applying rust encapsulator platinum on any pitted areas of metal.

How do you fix pitted paint?

0:242:57DIY: How to Repair Paint Stone Chips - YouTubeYouTubeStart of suggested clipEnd of suggested clipBut you need to be very careful not to damage the existing paint if the heat gets too intense nextMoreBut you need to be very careful not to damage the existing paint if the heat gets too intense next wipe down the stone chips using a rubbing alcohol just remove any residue left over from wax soap.

How do I fix chrome pitting?

Step One: Clean Chrome Surface. Use a microfiber or soft cotton cloth, your choice of soap, and warm water to clean the chrome's surface. ... Step Two: Polish the Chrome. Once the surface is clean, run a fingernail along the worst of the pitting. ... Step Three: Reapply Clear Coat.

How do you remove pitting from stainless steel?

Black spots on stainless steel cookware are usually the result of the polishing process, and they are most common on new pots and pans. Remove these by pouring olive oil on the deposits, allowing it to sit for a while, then washing the pot with dish soap, warm water and a nonabrasive sponge or cloth.

How to remove pitting from metal?

Step 1. Attach the wire brush to the drill and apply to the metal. Work on the worst-affected areas first, removing as much of the rust and flaking metal as possible. Work outward and then return as you remove the pitting from the metal.

Why do I need to clean pitted metal?

Metal primer. Pitted metal needs to be thoroughly cleaned of rust. Pitted metal is caused by rust eating down below the surface of the metal. It causes an uneven surface that must be smoothed out before it can be used or painted. It's vital to remove all the rust when working with the metal or the problem will simply return.

How to smooth rust off metal?

Step 1. Attach medium-grit sandpaper to a sanding block and the sand the metal you've just cleared of rust. Move the block in circles over the entire area to smooth any ruts and ridges. Wipe the area clean with a cloth and use your fingertips to test for smoothness.

How to smooth out scratches on metal?

Grind lightly across the area and around the edges; this will help smooth out much of the pitting and scratches. Grind lightly around the edge of the affected area, although don't extend too far out onto the rest of the metal. Advertisement.

Why is it important to remove rust from metal?

It's vital to remove all the rust when working with the metal or the problem will simply return. Once the metal is smooth, it needs to be protected to prevent further oxidization.

How to treat rust pits on Eastwood fender?

In order to properly treat, fill and prep the fender, just follow these easy steps: Apply Eastwood Fast Etch to the area with the rust pits. Cover the area with plastic wrap to prevent the Fast Etch from evaporating before it can work. Fast Etch eats into the rust, dissolving it and leaving clean metal behind. ...

How to get rid of dust on floor?

Blow off the dust with an air gun, then wipe clean with PRE paining prep. Mix up your body filler and spread thinly and evenly over the entire surface, most of it will end up as dust on the floor eventually. Sand first in one direction, than in another, producing an X pattern of sanding passes.

Can you use body filler over rust?

The Rust Encapsulator in the pits will keep any microscopic rust from growing, allowing you to safely apply body filler over it. Body filler alone won’t seal out moisture the way a dedicated product like Rust Encapsulator does because it is porous. Now proceed with your normal body work as if the rust was never there.

How to repair a crack in aluminum skin?

To repair the crack, after you stop drill it, rivet a small sheet metal patch of the same type and thickness metal over the crack to restore the area's strength and to keep vibration from acting on it further (see Figure 1). If you have a crack in a 0.032-inch aluminum skin, stop drill both ends of the crack .

What is the first step in a repair process?

The first step in any repair process is assessing the damage to determine whether it's simple or major. Minor damage to a sheet metal structure includes missing or damaged rivets, scratches or small dents, a small crack, and a corroded sheet metal surface. Damage that exceeds the scope of these items is, in most cases, major. For example, deformed rivets often indicate damage to a sheet metal structure, and your inspection should include an area well past the deformed rivets.

Why is it important to drill out rivets?

Your goal is to remove the rivet without enlarging its hole or damaging the sheet metal. The strength of a riveted piece is based upon the rivet's expanded diameter. This is why it's important to drill out the rivet using the proper size drill and to replace it with a rivet of the proper diameter and length.

What size drill bit do I need for a 5/16 rivet?

The most common rivet diameters are 3/32-inch and 1/8-inch, and their corresponding drill bit sizes are 40 and 30, respectively. A 5/32-inch rivet requires a size 21 drill bit, and a 3/16-inch rivet requires a size 11 bit.

Can you drill a rivet head farther than the rivet head?

(Don't forget your eye protection.) When removing rivets, do not drill any farther than the rivet head.

What is a damaged control surface?

A damaged control surface is an example. The repair might be simple, but any change to the surface affects its balance, which can lead to flutter in flight. To complete the repair, you'll need to rebalance the surface and perhaps other components or surfaces attached to it.

Can you replace a rivet on a plane?

When replacing a rivet, use the exact same type originally used. If you built the airplane, you should know this information.

Can fiberglass pop off metal?

Fiberglass and sheet metal expand and contract at different rates, fiberglass will just simply pop off the metal. If you are not possitive that you have ALL the holes filled, use a product called All Metal, the stuff is the absolute shits to work with, but is better than anything with fiberglass in it.

Can you weld pinholes in a car trunk?

If you get inside the trunk and see light shining through lots of holes in the fenders, then you can either weld the pinholes shut if they're small, or cut out large rotten areas and make patch panels.