How to Fix a Stripped Screw Thread with Inserts

- Remove the Bolt. The first thing you will need to do is remove the bolt. ...

- Clean the Remaining Threads. Once you have removed the bolt, use a clean rag, some compressed air, and penetrating oil to cleanse the remaining threads.

- Find the Right Drill Size. ...

- Screw the Thread Insert onto the Installation Tool. ...

- Screw in the Thread Insert

How do you fix a damaged thread?

If a male thread (a screw or a bolt for instance) is damaged, it can often be fixed by ascertaining the thread pitch by utilizing a screw pitch gage, and then running the appropriate thread file over it. (Watch a video of this method of thread repair here ).

How do you install a thread repair insert?

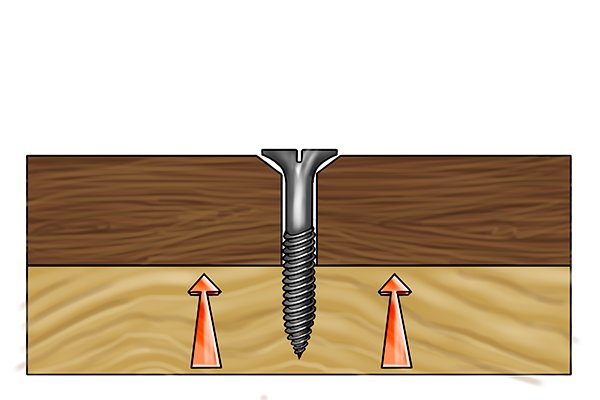

Types of thread repair inserts: Installation: Normally use a square or six point installation drive tool to screw the insert into a freshly retapped hole, then locking the insert into place by hammering the knurling at the top of the insert into place.

Can a hole in a tap thread be repaired?

For repairing holes, this is not as big of an issue, as you are likely following existing threads, but if your threads are severely damaged, threading the hole at an angle is a very real possibility, so take care to ensure your tap is at the correct angle to the part, nearly always 90-degrees. The threads on this rack and pinion has been damaged.

What are the different types of thread repair inserts?

Thread-repair inserts come in a variety of materials and in a myriad of designs from domestic and overseas manufacturers. Timed thread body inserts, wire coil inserts and keyed inserted make up the three major families of thread inserts you’ll likely encounter.

Can a damaged thread be repaired?

Damaged threads on a screw or bolt can often be fixed by running a die over it, and if a thread's damage is minimal, it may be possible to reform the threads by running a nut up and down them, though that runs the risk of the nut fusing to the thread (galling).

How do you fix damaged threads?

0:175:40Thread Repairs - YouTubeYouTubeStart of suggested clipEnd of suggested clipWhen. You set that opening over the bolt. Hold everything level and start turning it slowly to letMoreWhen. You set that opening over the bolt. Hold everything level and start turning it slowly to let it engage the threads.

How do you fix a stripped thread hole?

2:168:36How To Fix a Stripped Out Bolt Hole - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo it's really easy to cross thread one in there and tear the threads up and then you go to cinch itMoreSo it's really easy to cross thread one in there and tear the threads up and then you go to cinch it down and you just pull the rest of the threads out.

Can you use Loctite on stripped threads?

Loctite® Form-A-Thread® It restores worn, stripped or damaged threads and eliminates future corrosion, galling, seizing, and rust, and allows up to 128 ft. lbs. of torque between -65°F to 300°F. It permanently repairs stripped threads and fasteners in five minutes (up to SAE Grade 5 English and 8.8 metric).

How do you fix a stripped screw hole in metal?

How Do You Fill Stripped Screw Holes in Metal?Use a specialized bit to enlarge and thread the hole, then insert a new screw.Drive a larger-diameter, self-tapping screw into the hole.Fill the hole with metal epoxy, then drive the original screw back into the hole.More items...

How do you fill a hole in a screw again?

2:475:43How to Repair Stripped Screw Holes. GOOD ONE! This Video ... - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo the first thing you do is just with a bit of carpenters glue just squeeze some in the hole. Don'tMoreSo the first thing you do is just with a bit of carpenters glue just squeeze some in the hole. Don't get too crazy squeeze a bit in probably with your finger.

How do you fix a screw that won't tighten?

0:073:46How To Fix Screws That Won't Stop Turning - YouTubeYouTubeStart of suggested clipEnd of suggested clipOkay that's the goal the point should be small enough that it could fit into the hole that the screwMoreOkay that's the goal the point should be small enough that it could fit into the hole that the screw went into I have two wooden blocks right here and I'm just going to use my hammer.

How do you fix a screw that won't tighten metal?

0:177:5413 Annoying Loose Screws Around the House & How to Fix ThemYouTubeStart of suggested clipEnd of suggested clipAnd you can also apply a product like the thread stopper tape wrap it around a couple of times onMoreAnd you can also apply a product like the thread stopper tape wrap it around a couple of times on the threads. And that will hold it in there a lot easier and a lot longer.

Which of these may be used to restore damaged threads on a bolt?

A rethreading kit is an important part of any automotive toolbox. Use it to restore stripped threads on old, rusty nuts and bolts when you don't have time to search the stores for a replacement.

Can you use a tap to repair threads?

6:1511:17How To USE A TAP AND DIE To FIX DAMAGED THREADS ... - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo we just went ahead and fixed those threads. Not too shabby. So that's how you use a tap to fix aMoreSo we just went ahead and fixed those threads. Not too shabby. So that's how you use a tap to fix a stud or threads of a bolt. Let me show you how to use a tap. So a tap is going to fix a hole.

How do you renew a thread?

The thread repairDrill thread. First you drill the damaged thread with a twist drill. ... Cut thread. Now you can cut the new thread with the single-cut tap. ... Insert thread insert. Put the thread insert on the fitting-tool or directly into the hole (see second picture below). ... Break pin.

How to repair a stripped thread?

Similarly, when threads are stripped out of a hole, there are a number of approaches one can take to repair them. Drilling out the hole and tapping it with a larger diameter thread is one option, provided there is room for a larger fastener. When creating a new, larger tapped hole isn't optimal or possible, use of a thread repair kit is recommended.

What is a thread repair kit?

They may also be used to create strong threads in soft materials including aluminum. Thread repair kits consist of a tapping tool, an insertion tool, and thread inserts. A tap wrench and drill will also be necessary when using a thread repair kit. The drill bit is not always included in the kit. The most popular type of thread insert used in ...

What to do when you have a tapped hole?

When creating a new, larger tapped hole isn't optimal or possible, use of a thread repair kit is recommended. Thread repair kits allow you to remove the damaged threads that are stuck in a hole and replace them with new threads of the same diameter.

Why use helical thread insert?

An installed helical threaded insert can provide a more secure threaded connecting point and overall stronger threads.

Why does my thread get damaged?

Typically, thread damage is caused when a tap or fastener breaks in a hole, when a fastener is installed incorrectly , when incorrect bolt torque is used, or when thread fretting occurs as a result of extended or extreme vibration ...

What is the tension between the insert and the walls of the hole?

The tension between the insert and the walls of the hole helps to keep the insert in place and keep it from unthreading. The helix has a small return at one end that engages with the kit's included insertion tool, allowing the insert to be screwed into the hole.

How to break off a tang?

Break off the tang where the thread insert wire returns across the hole (A hex tool can be inserted through the new thread to rest against the tang and it typically will snap off easily with the light tap of a hammer).

What is thread repair insert?

Thread-repair inserts come in a variety of materials and in a myriad of designs from domestic and overseas manufacturers. Timed thread body inserts, wire coil inserts and keyed inserted make up the three major families of thread inserts you’ll likely encounter.

How to repair M10x1.25 thread?

For an M10x1.25 thread repair with a Keensert, a 12.5mm drill would be used for the M14x1.5 tap. The M14x1.5 tap would have a major diameter up to 14.4mm (an M10 repair with an S.T.I. tap would only have a 11.787mm major diameter). That’s a much bigger hole which can be beneficial in some application where severe corrosion is prevalent in the original threads. The Keensert would then be threaded into the drilled, tapped and cleaned hole with the Keensert installation tool. Thread locking compounds can be used due to its solid body design. Once set in position, the installation tool is then used to drive in the four key stakes into position. This provides the ultimate mechanical locking of the insert in place. Hence, this design sports exceptional resistance to vibration. Now the downside. The massive outside diameter of the insert makes it unviable in applications where the material around the original threaded hole is limited, such as any “thin-wall” castings. Second, the cost for a standard-steel Keensert is about 4.5 times that of a HeliCoil and more than double the cost of a TIME-SERT. If you want a stainless-steel Keensert, the cost goes through the roof being about 25 times the cost of a HeliCoil.

What size drill do I use for a M10x1.25?

First, you would drill the hole with a 10.25mm drill (a standard M10x1.25 thread would use a much smaller 8.75mm drill). Then you would use an M10x1.25-S.T.I. tap. This S.T.I. version of the tap will have a major diameter of up to 11.787mm, whereas a standard M10x1.25 tap is about 1.5mm less in diameter.

How hard is it to drill a stripped hole?

How easy or how hard usually depends on the access to the stripped hole. If you can take off the entire header and get enough access to fit a cordless drill in the area to drill out the hole before tapping, it pretty easy. I;'m guessing it would probably be an M8x1.25 thread. Compare the size and thread on one of the good bolts to a know M8x1.25 bolt to confirm.

Can you have a thread failure in the same hole again?

Done right, you’ll never have a thread failure in the same hole again.

Is stripper thread more common than ever?

As a result, it’s no surprise that strippers are more common than ever before. Since most of the threads on today’s vehicles are made of materials with just one-third to one-half the hardness of grey cast iron, it’s no wonder that more threaded holes experience thread damage than ever before.

Can Keensert be threaded?

That’s a much bigger hole which can be beneficial in some application where severe corrosion is prevalent in the original threads. The Keensert would then be threaded into the drilled, tapped and cleaned hole with the Keensert installation tool. Thread locking compounds can be used due to its solid body design.

How to get chips out of a thread?

Once the threads are cut, you need to clean out the hole. Spray it with compressed air, brake cleaner or lubricant to get all the chips out.

How do threaded parts work?

They are twisted by hand, and slowly work their way into hole being tapped. Threaded parts such as bolts, shafts, and other similar parts use dies to cut the threads. This is done in a similar manner as a tap, but the shaft of the part threads through the die as it cuts the threads.

What is a taper tap?

The taper tap is the most common tap design. This is the style used for creating new threaded holes. The first 8 to 10 cutting flutes of the tap are not full, they gradually build up to the full thread size. The taper is there to guide the tap in the hole and to slowly cut the threads in fresh material.

Why do taps have tapered flutes?

The tapered flutes help ensure that the tap is centered and vertical. We ran the tap all the way through the part, so that the bottom threads were touched by the full flutes of the tap. The chips in the relief grooves of the tap are called swarf, they should be cleaned off before putting the tap away.

How many flutes does a plug tap have?

The plug tap is in the middle, it uses 3-5 gradual flutes. Each tap style serves a different purpose. From the left- taper, plug, and bottoming. If you are repairing damaged threads, either of these taps will usually work, unless it is a blind hole, in which you need to use a bottoming tap.

What happens if threads don't match?

Some pitches overlap different sizes, so you have to use the chart to determine what size fastener you have. Thread size and pitch is critical to this type of repair. Using this style of pitch gauge, you can determine exactly what you have.

What happens when you strip a bolt?

When you strip one out or break a bolt inside the hole, the threads are damaged. In some cases you can re-tap the threads with good results, but if the fastener is under high load or critical, then you will likely have to go to the next size up. These holes use taps, which cut threads into the metal.

What is a thread repair insert?

Thread repair inserts, allow for threads to be repaired, recreated, or reinforced to the original bolt size and pitch. Solid inserts which are often made of stainless steel or carbon steel, can not only be used to repair damaged threads but also to reinforce soft base metals like aluminum to be able to take a much higher torque.

Can you fix threads?

There are many not so ideal ways of fixing damaged threads by way of oversizing and cross threading; but what a lot of people don’t know is that there are many engineered solutions to properly fixing damaged threads. Even more problematic is that most people are only aware of coil based repair kits (like helicoil or permacoil).

Do self tapping inserts require a pretapped hole?

Self tapping (gardsert/seal-lock/ensat) Installation: The easiest method of all, these types of inserts do not require a pretapped hole, as they create their own threads as they are installed. They also do not require special installation tools and utilize a normal nut and bolt for installation.