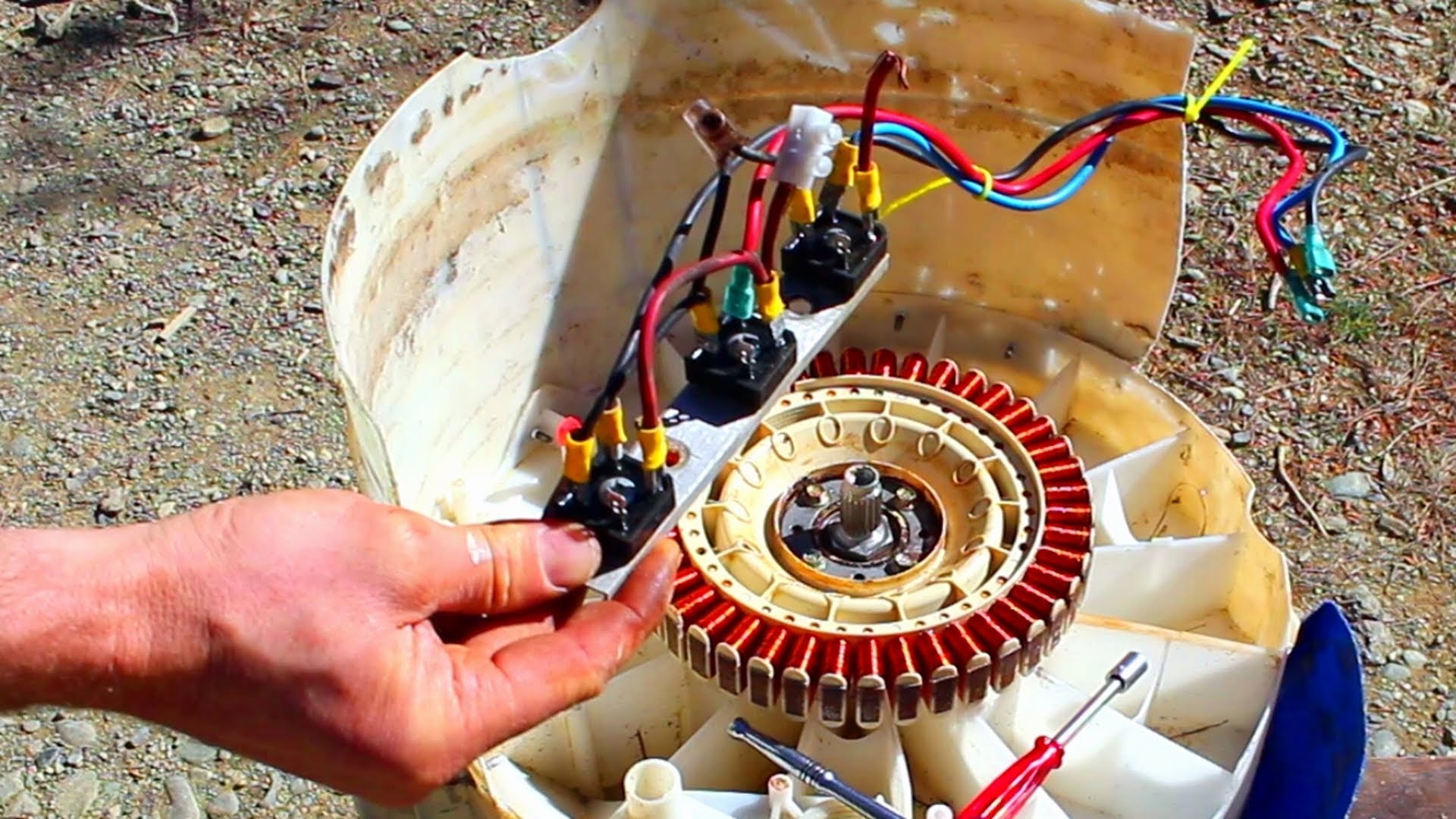

Servo Motor Repair Process:

- Initial Evaluation. During an evaluation a visual inspection is performed to check parts like the shaft, keyway, endbells, terminals and connectors.

- Disassembly. First, the backplate is removed, followed by the encoder and encoder housing while carefully disconnecting the wiring.

- Bearing Change. ...

- Final Testing. ...

How to get your servo motor repaired?

Servo motors repaired and delivered in five business days. 48-hr rapid turnaround available on most repairs for a 15% expediting fee. Call 866-80SERVO (866-807-3786) Request a servo motor repair online

How to repair small DC motor at home?

The Simple DC Motor

- Starting to Built. TOP surface of the wire. ...

- Preparing to Assemble. Strip the other straight section of wire completely – top, bottom and sides. ...

- Twisting Paperclips. Place the ceramic magnet in the middle of the wooden base. ...

- Proper Arrangement. Using thumbtacks, secure the paperclips to the wooden base. ...

- Help. • Has the rotor been stripped correctly? ...

How to modify a servo?

What you need:

- 1 x Acoms AS-12 Servo (or similar servo by GWS, Parallax, or Tamiya, etc)

- 2 x 220 ohm resistors

- Soldering iron

- Small side cutters

- Small jewerlers screwdriver set

How to reduce the noise of a servo motor?

How Fix Servo Motor Noise

- Give your amplifier a wellness check

- If none of the above current and amplifier related suggestions solve your noise problem, it may be time to do a wellness check on your amplifier.

- Grab a current probe and try this test: Lock the rotor and send a sinusoidal current command to the amplifier. ...

How do I fix my servo drive?

Make sure to clean or remove particles, dry out any plugs and check all cables. Check for a bind in the axis or if the brushes are worn down in the DC motor. Use a volt ohm meter to check for an incoming power supply. You'll mainly want to test the servo drive to ensure the voltage is correct.

How do I know if my servo motor is broken?

When the gear fails (broken tooth, hard point, etc.), the servo may get stuck, free moving or any combination. When the motor breaks (usually the brushes inside the DC motor are the culprit), the servo stops working altogether (as if it was unplugged) or overheats and burns.

What causes a servo to fail?

Bad winding is a common cause of servo motor failure. These copper coils within the motor can be compromised due to water contamination—or more slowly over time thanks to natural vibration as the motor runs.

How do you replace a servo motor?

1:023:24Replace Servo Motor - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo pretty much the easiest way to do this is unmount the servo motor with these two screws here. AndMoreSo pretty much the easiest way to do this is unmount the servo motor with these two screws here. And even from model to model they're. Still going to be mounted. The same way with just two screws.

Can servo motors be repaired?

Servo motor repair is claimed by many but mastered by few! There are many steps involved in repairing servo motors; the trickiest step is in the feedback repair and realignment.

How do you test a servo motor?

How to Test a Servo MotorUsing an Ohm Meter. Disconnect ONLY 3-phase motor lines (T1,T2,T3) from the drive. ... Using a Megaohm Meter. Test all three wires (T1,T2,T3) separately. ... Test for Open or Short in Windings Using an Ohm Meter. Test the connections from T1 to T2; T2 to T3; then T1 to T3.

How long do servos last?

In ideal conditions a servo motor can last 20+ years, and under extreme conditions can last less than one year. Most OEM (original equipment manufacturers) contribute the lifespan of their servo motors to the lifespan of the bearings.

What is a servo problem?

Servo Motor Running Hot A motor running hot is a serious problem that can eventually lead to a catastrophic failure for the motor or even other parts of the machine. Overheating can be caused by an overcurrent condition on the machine.

What causes servo motors to overheat?

There are some reasons for servo motor overheating as following: too large load, phase failure, air duct obstruction, low speed running time too long, excessive power supply harmonic and so on.

How do you fix a servo valve?

0:562:24Moog Servo Valve Repair Process - YouTubeYouTubeStart of suggested clipEnd of suggested clipThen the industrial ultrasonic cleaner is used to wash the precision components. After a thoroughMoreThen the industrial ultrasonic cleaner is used to wash the precision components. After a thorough cleaning of the internal components. The technician completes the correct level of repair.

How do you take apart a servo?

0:475:22How to Replace a Servo Gear Set - The Secret Life of Servos Ep8YouTubeStart of suggested clipEnd of suggested clipAnd then pull up on the mounting tabs. And the top should just pop right off. Now. This can be aMoreAnd then pull up on the mounting tabs. And the top should just pop right off. Now. This can be a little bit daunting the first time you see all the gears inside of a servo.

What is servo motor encoder?

A servo motor encoder detects the rotation angle, speed, and travel distance of a moving machine part and sends positional feedback to the controller. The controller sends electrical signals to the driver, which amplifies and translates the signals for the servo motor.

How do you tell if a servo is burnt out?

1:055:27Digital Hobby Servo Burnout - To Repair, or To Not Repair - YouTubeYouTubeStart of suggested clipEnd of suggested clipEven is black and there again the board is black right there so if we look at this board. There's aMoreEven is black and there again the board is black right there so if we look at this board. There's a MOSFET right there melted. And there's another one on the other.

How long do servos last?

In ideal conditions a servo motor can last 20+ years, and under extreme conditions can last less than one year. Most OEM (original equipment manufacturers) contribute the lifespan of their servo motors to the lifespan of the bearings.

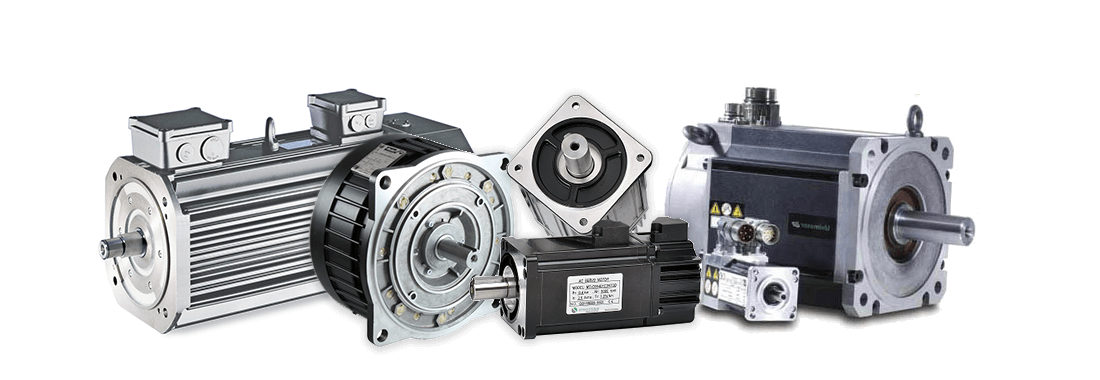

What is servo motor?

Servo motors are specifically designed to withstand high amounts of holding current as well as extremely fast start stop procedures so that accura cy can be maintained at all times.

How to check if servo motor is wobbling?

Assuming the prior tests have all passed, apply a small voltage starting from 0 volts to the armature winding of the servo motor. Slowly increase this voltage using your variable power supply until the shaft begins to turn. It is at this point you can further evaluate whether there is unnecessary vibration of the servo motor during rotation or whether the shaft appears to wobble or “bounce” due to a bent shaft or bad bearing.

Why does my servo motor bounce?

If there is “bouncing” when attempting to rotate the shaft then it is likely due to a short within the motor or a bearing beginning to fail. In either case, it is bad and the servo motor will need to be disassembled for further diagnosis.

Why does the shaft of a servo motor rotate?

This is assuming you have actually disconnected the cables from the original servo drive. The drive often causes resistance when rotating the shaft if it is connected to the servo drive through the motor cables.

Why are servo motors calibrated?

All servo motor and servo drives are mechanically calibrated between multiple facets of the unit to ensure the proper positioning of the device when it is commissioned. Failure to properly dis assemble a servo motor or drive can actually cause the unit to become unusable in the future.

How many phases are there in a motor cable?

For the motor cable, you are looking at 3 separate phases, 2 armature wirings and sometimes commutation wiring. Using your meter, test the end of each cable to ensure there are no shorts between any of those connections.

What is field service tech?

Our field service techs are trained to troubleshoot any issue ranging from standard AC Motor Speed Controllers to advanced robotics and PLCs. They are trained to establish cause of failure as quick as possible.

What is a servo motor?

Servo motors are immensely useful tools that pack a powerful punch for their size . They are similar to AC/DC motors, except they have an additional positioning device. The attached positioning device offers useful feedback for providing extra control in a closed system loop.

What causes a servo motor to malfunction?

One possibility is that the servo motor could have an inadequate power supply or a bad drive. In this case, the motor itself is fine, but failures of the external systems cause it to malfunction.

Why does my servo squeal?

Dusty brakes can also cause a high-pitched squeal from your servo motor. If your servo motor has a brake, dust from the brake pads may have infiltrated the brake itself. Then the dust can move to the bearings, soak up the oil , and lead to friction and screeching. Even though servo motor bearings usually have shielding, dust can often find a way to creep in and compromise them.

Why is feedback important in servo motors?

Part of our rigorous review includes feedback testing and repair. This maintenance is necessary because it ensures your servo motor and drive are at top performance. Feedback devices give us a way to deliver information to the control for speed, rotation direction, position accuracy, deceleration, acceleration rates and relative position of the rotor to the stator.

How to tell if servo motor is overheating?

To figure out what’s happening, check the wiring, cooling system and bearings. The cooling system may have become impeded because of debris or dust particles. The bearings may be worn down, have too much lubricant or be overheating. Or the wires may be burning because they have come into contact with each other or are improperly grounded. It’s also possible that the coolant has seeped into the electrical box.

Why does my servo motor make a noise?

A positioning error can also cause problems for your servo motor. If this happens, the motor will stand still and make a buzzing or chattering noise, and the output shaft will waver slightly, even though it is at rest.

Why is my motor chattering?

Setup issues and parameter losses can cause similar chattering issues to those caused by positioning errors. You can check to see whether these issues are the cause of the malfunction by running through the setup procedures for the motor and drive. If not, a feedback issue in the motor may require repairs.

What is a servo motor?

A servo motor is a torque-based engine comprised of a rotary actuator or linear actuator. This type of motor allows for precise controls adjusting for angular and linear position, torque, velocity and acceleration. Four components, motor, a drive, controller and feedback unit, comprise modern servo systems. Servo motors are usually quite small, but ...

Why does my servo motor only put out torque?

By nature, motors will only put out a certain amount of torque so that if you choose the wrong one, it may not be able to handle the workload your team needs it to. Sometimes, you may also have a servo motor malfunction, and it will cease producing enough torque.

Why is an overheating servo bad?

An overheating servo is never good because the elevated heat levels can damage your equipment and even ruin other parts of your connected system. Any good servo will have a failsafe, of course, and shut down when the temperature surpasses a dangerous threshold. That doesn’t change the fact that it can cause severe damage to company’s equipment and waste a lot of your team’s time.

Why does my servo make a noise?

If the servo does make strange noises, the problem is most likely incorrect wiring or electrical issues. Check to make sure the servo is grounded properly and that it’s getting the appropriate amount of power. Obviously, be sure the servo is off before working on the electrical circuits.

What is the most common noise a servo drive or motor will produce during normal operation?

A servo motor will always make a small amount of noise, it’s natural. Humming is the most common noise a servo drive or motor will produce during normal operation.

What are the components of a servo motor?

Four components, motor, a drive, controller and feedback unit, comprise modern servo systems. Servo motors are usually quite small, but they still pack a lot of power and efficiency which is why a lot of applications use them, namely industrial. You’ll find them in industries like robotics, metal cutting and forming, printing, woodworking, ...

How to check if servo drive is working?

Turn on the machine or main breaker and check the LED or readout display. If there is a screen and it does not come on, make sure there is power supplied. If the alarm comes on immediately before anything else powers on, then your problem is probably the servo drive. If the drive begins working before the alarm sounds, you can rule it out.

What is servo motor?

Servo Motors are used in equipment where precise control of the shaft position is needed. Servo Motors run on many of the same principles as regular AC and DC motors save for the fact that they have a positioning device attached to provide feedback for a closed loop system control. Being successful in maintaining a servo system means understanding ...

Why does my servo squeal?

If your motor has a brake, there is a chance that dust from the pads has crept into the bearing space and entered the bearing. Usually servo bearings are shielded but still can creep into the bearings drying up the lubricant. If running through normal troubleshooting does not fix the issue, such as settings and parameters, then the servo needs service most likely involving a bearing change. Do not let this problem linger, as it will get worse over time and lead to the motor failing.

Why is my motor running hot?

A motor running hot is a serious problem that can eventually lead to a catastrophic failure for the motor or even other parts of the machine. Overheating can be caused by an overcurrent condition on the machine. Mechanical binding, brake issues or overload issues should be explored first. Once all mechanical issues have been ruled out, it is important to inspect the output shaft of the motor and spin it to check for bearing failure. Next you will want to check the windings for any issues such as contamination or internal shorts.

What is the purpose of inspecting the output shaft of a motor?

Once all mechanical issues have been ruled out, it is important to inspect the output shaft of the motor and spin it to check for bearing failure.

How to contact Global Electronic Services?

Be sure to visit us online at gesrepair.com or call us at 1-877-249-1701 to learn more about our services.

Can servo bearings be shielded?

Usually servo bearings are shielded but still can creep into the bearings drying up the lubricant. If running through normal troubleshooting does not fix the issue, such as settings and parameters, then the servo needs service most likely involving a bearing change.