Repairing spalling concrete

- Remove the spalled concrete

- Clean and paint the corroded steel bars

- Patch the hacked area

- Paint the area. While waiting for the repairs, do remove any loose spalling concrete to prevent injury to your family members.

- Clean Spalled Concrete Area. Ad. ...

- Remove Loose Concrete. Remove loose and broken concrete from the area using hammer and chisel. ...

- Clean and Coating Corroded Steel Bars. ...

- Apply Repair Material Mixture. ...

- Finishing. ...

- Curing. ...

- Apply Pain or Coat on Repaired Surface.

How do you fix spalling concrete?

If your concrete is spalling, these are the repair options: Patch the spalled area with a color matching compound Have your concrete resurfaced with an overlay Rip out and replace the entire slab

What is spalling concrete?

Spalling concrete is a common problem where part of the surface peels, breaks or chips away. Also known as scaling, it is the result of a weak surface that is susceptible to damage. Find concrete repair contractors near me.

How do you fix a bent concrete column?

Shore the column and remove and replace the in-place concrete. Shore the column and increase the size of the column to reduce the bending stresses, and to increase the confinement on already placed weak concrete. Wrap the column with carbon- or glass-reinforced plastic.

How do you repair cracks in a concrete column?

Methods of Concrete Column Repair for Damages and Cracks. Columns may be repaired by using one or more of the following methods: Encasement or enlargement of the column cross section (jacketing). Cathodic protection to stop reinforcing steel corrosion. Re-alkalization of the reinforcing steel to stop corrosion.

Can you repair spalling concrete?

If your concrete is spalling, these are the repair options: Patch the spalled area with a color matching compound. Have your concrete resurfaced with an overlay. Rip out and replace the entire slab.

How do you resurface concrete spalling?

Mix one part Type 1 Portland cement and one part fine sand by volume. Add water until the mixture is the consistency of thick paint, then brush it on the damp concrete.

What is spalling concrete column?

0:094:13What is Concrete Spalling? Their Causes and Prevention. - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo let's get started. Spalling is breakaway of concrete surface which often extends to the topMoreSo let's get started. Spalling is breakaway of concrete surface which often extends to the top layers of reinforcing steel spawns maybe 150 millimetres or more in diameter and 25 millimetres or more

How do you strengthen weak concrete columns?

There are three major techniques for strengthening reinforced concrete columns which are discussed below:Reinforced Concrete Jacketing. It is one of the techniques used to improve or restore capacity of reinforced concrete column. ... Steel Jacketing. ... FRP Confining or Jacketing.

Can you resurface crumbling concrete?

You can repair and resurface your spalled concrete in any number of ways. You can buy products that apply a very thin coating on the concrete. The larger premixed bagged concrete manufacturers make these, as do some other specialty companies. These products do work, but pay close attention to their limitations.

What does spalling concrete look like?

Spalling looks like pitted acne scarring and breaks off in flecks which can expose rebar. These divots vary in diameter and depth but can be thicker than 5 inches and just under an inch in depth.

Can concrete columns be repaired?

Columns may be repaired by using one or more of the following methods: Encasement or enlargement of the column cross section (jacketing). Cathodic protection to stop reinforcing steel corrosion. Re-alkalization of the reinforcing steel to stop corrosion.

Is concrete spalling serious?

Concrete spalling is also known as concrete cancer. It has the capacity to cause serious hazards, public injury, and loss of public property, as it can damage the whole structure, like damage to reinforcing bars within the concrete. Hence, spalling concrete is an issue that needs attention.

What causes spalled concrete?

There are a number of reasons why spalling occurs including freeze thaw cycling, the expansive effects of Alkali Silica Reaction or exposure to fire. However, the most common cause of spalling is the corrosion of embedded steel reinforcement bars or steel sections.

Which method is used for strengthening of column?

External steel reinforcement method Reinforcing concrete columns with outer steel is a method of strengthening the four corners of the column with section steel. Its advantages are simple construction, less on-site workload, and more reliable force.

Is it OK to drill concrete column?

Drilling into concrete pillars, especially load-bearing pillars, can cause concerns for the structural safety of your condo unit and the building as a whole. Drilling can weaken the concrete and cause additional cracks to form, compromising your safety.

How do you reinforce existing concrete?

Methods to Strengthen Concrete Walls.Concrete Jacketing.Concrete Replacement.Retrofitting by Steel Materials.Retrofitting using Shape Memory Alloys (SMA)Use of FRP Laminates.

Why is top layer of concrete flaking off?

Damage will show up when the concrete is exposed to ice or snow which then melts and penetrates into the concrete and freezes. Frozen water expands about 10%, pushing the thin, weak top layer upwards causing the layer to peel off (known as spalling).

How do I fix my garage floor spalling?

0:222:33How To Repair Concrete Spalling - YouTubeYouTubeStart of suggested clipEnd of suggested clipTake one of the adhesive. Compounds and there's quite a number of them different. ProductsMoreTake one of the adhesive. Compounds and there's quite a number of them different. Products throughout the industry for welding concrete to concrete.

How do you fix concrete scaling?

Repairing Concrete ScalingRemove loose concrete and clean the surface of any dirt and debris.Dampen the cleaned concrete area and apply a thin layer of cement paste before concrete placement for resurfacing.Place proper concrete type to resurface the damaged area.More items...•

What causes concrete to spall?

There are a number of reasons why spalling occurs including freeze thaw cycling, the expansive effects of Alkali Silica Reaction or exposure to fire. However, the most common cause of spalling is the corrosion of embedded steel reinforcement bars or steel sections.

Why is my driveway spalling?

Common mistakes include adding too much water to the mix, to make it easier to pour; sprinkling the surface of the concrete with water, to extend finishing time; and not curing the concrete properly after installation.

How to get a nice finish on concrete?

Timing is the secret to getting a nice finish. Use the bull float immediately, but wait until the concrete stiffens before using the edger and broom. All the tools you need are available at most rental stores. Cover the finished concrete with plastic for five days or spray it with a curing compound.

How to make a cement wheelbarrow?

Mix one part Type 1 Portland cement and one part fine sand by volume. Add water until the mixture is the consistency of thick paint, then brush it on the damp concrete. Before that dries, mix three parts fine sand and one part Portland cement in your wheelbarrow with enough water to make the mix the consistency of thick oatmeal.

What to do if you find spalled concrete?

If you find spalled concrete and you're unsure how old the concrete is or how and when it was poured, consider contacting a structural engineer or comparable professional to come and assess the structural integrity of the surface.

Why does concrete spall?

Spalls can appear because the rebar has been exposed and humidity and water have begun to rust the rebar or because the concrete joints were improperly built. As weather changes, the concrete expands, causing it to spall, which leads to further deterioration.

What does spalling concrete look like?

Spalling concrete can look like round or oval depressions along surfaces or joints. Spalling tends to be most common in cold climates when de-icing chemicals are applied or when seasonal freeze-thaw cycles damage the concrete.

How to prevent spalling after overlay?

After the overlay has set completely, a waterproofing membrane should be applied to prevent spalling from recurring. Patching may be a repair option for random or localized damage. Patches should extend at least four inches beyond the spalled areas.

Can you patch concrete with epoxy?

It's best if the old concrete surface is rough to provide tooth for better bonding. The best patching materials are Portland- cement-based or epoxy and should be mixed immediately prior to application, as directed by the manufacturer.

Can you repair spalling on concrete?

When the spalling damage is shallower than 1/3 of the concrete's thickness, the concrete usually can receive a surface repair. If the damage is greater than 1/3 of the depth, steel bars may need to be installed and a full depth restoration may be required. Corroded rebar, due to exposure, must be cleaned at the beginning of the restoration process.

What is supplemental column system?

If it is not possible to remove the load from the column, then a supplemental column system can provide an alternative method of support in combination with the repair of the existing column.

How to replace corroded ties?

Corroded Ties. The corroded ties can be replaced by adding stainless steel hairpin ties that are anchored into the concrete. It is often necessary to deposit extra material around columns to provide adequate cover over the supplemental ties.

What is surface repair?

Surface or cosmetic repair only covers local deterioration and structural repair restores or strengthens the affected columns. If the deterioration does not significantly reduce the cross section, the conventional concrete repair can successfully be employed.

Can supplemental steel be disturbed?

Supplemental Reinforcing Steel. The column ties can not usually be disturbed during the repair as it may cause buckling of the longitudinal bars. Hence, the supplemental vertical bars may be placed outside the original cage with extra ties.

Can concrete be removed from a column cage?

Concrete Removal. The removal of concrete within a column cage must only be done if the column is unloaded. Otherwise, the longitudinal bars may buckle and compression failure of column may take place.

Do you remove corroded reinforcing bars?

It is not necessary to remove the corroded reinforcing bar with reduced cross-sectional area if the loss is supplemented with additional reinforcing bars. The lap length of such a splice must be provided corresponding to the area lost by corrosion to either side of the corroded portion of the reinforcing bar that is supplemented. The partially corroded reinforcing bars that are left in place must be thoroughly cleaned by sandblasting to obtain bare metal. The bars with excessive corrosion must be replaced with fresh reinforcement having full laps on both sides.

Material Specification

The epoxy resins to be used in the mortar for the repair of spalled concrete shall have the standard requirements as mentioned in the table below:

Surface Preparation of Spalled Concrete

The surface upon which epoxy is to be placed shall be free of rust, grease, oil, paint, asphalt, loose material, unsound concrete, dust, or other harmful materials.

Applications of Epoxy Mortar

Epoxy primer coat shall be applied with the help of stiff nylon bristle brushes or hard rubber rollers, or spray gun depending upon the nature of the surface and extent of the work area.

Coverage of Epoxy Mortar

The coverage of the resin mix would depend on the system of resin used. However, as a general guideline, the coverage area shall be as under:

Handling Precautions of Epoxy Mortar

Epoxy resins can cause skin irritation to the people with sensitive skin, if incorrectly handled.

FAQs

What are the required bond and tensile strength of the epoxy mortar used to repair spalling concrete?

Can you repair spalling concrete?

If your concrete is spalling, these are the repair options: Patch the spalled area with a color matching compound. Have your concrete resurfaced with an overlay. Rip out and replace the entire slab.

How much does it cost to repair concrete spalling?

Repairs cost about $300 for spalling concrete in an area the size of a cellphone, to $1,200 for the entire ceiling of an HDB toilet, said Mr Ravits Goh, managing director at A & R Construction and Engineering, an HDB-approved contractor.

How do you resurface a concrete wall?

Fill in any cracks and gaps with concrete resurfacer. Use resurfacer for cracks 1/8-inch wide. For cracks 1/2-inch wide, fill in with concrete repair caulk. Insert the repair caulk tube into a caulking gun to squeeze out the agent.

What does concrete spalling look like?

Spalling concrete can look like round or oval depressions along surfaces or joints. Spalling tends to be most common in cold climates when de-icing chemicals are applied or when seasonal freeze-thaw cycles damage the concrete.

How do you stop concrete spalling?

Preventing weather-related spalling requires using air-entrained concrete, curing well, and applying a water-repellent sealer after the slab is cured.

Is concrete spalling dangerous?

Concrete spalling is more common in colder climates, where the concrete endures freeze-thaw cycles. Because spalling can be a sign of deep, dangerous damage that can result in further issues, it’s important to repair spalling at the first sign of brokenness or flaking.

What causes spalling in new concrete?

In most cases, spalled concrete is caused by poor finishing and the use of water on the surface to aid in the finishing process. Excess water and overfinishing create a weak surface that can’t handle freeze-thaw expansion and contraction.

Can spalling concrete be repaired?

If your concrete is spalling, these are the repair options: Patch the spalled area with a color matching compound. Have your concrete resurfaced with an overlay. Rip out and replace the entire slab.

How do you repair a crumbling concrete wall?

You can repair the damage by brushing on a bonding agent that lets new concrete stick to the old, then patching the wall. First, prepare the area to be patched. Remove all loose material with a small paint scraper, then brush off the dust.

What does spalling concrete look like?

Spalling concrete can look like round or oval depressions along surfaces or joints. Spalling tends to be most common in cold climates when de-icing chemicals are applied or when seasonal freeze-thaw cycles damage the concrete.

Does salt deteriorate concrete?

The answer is yes, salt does indirectly damage your concrete driveways, patios and sidewalks. Bumps and potholes don’t just appear due to regular wear and tear – salt damages concrete over time by causing corrosion to occur under the surface, leading to discolored, cracked and crumbling concrete.

Why are my basement walls flaking?

This occurs from deterioration caused by moisture. This moisture could be from penetration through the surface of the concrete, as would occur on a sidewalk or driveway, or from moisture moving through the concrete. In the worst cases, this moisture can cause the cracks to expand and the surface to spall.

What causes concrete blocks to crumble?

Water is the primary cause for most crumbling concrete. Whether from flooding or from repeated rains, water eventually wears down the structure of a cinder block from the outside, causing it to flake off and crumble. If a block has not been properly cured, water can also infiltrate the interior of the block.

Does concrete adhere to concrete?

QUIKRETE® Concrete Bonding Adhesive (No. 9902) permanently bonds new concrete, plaster, and stucco to existing concrete, plaster, and stucco. Eliminates the need for roughing the surface before the application.

Get Rid of Concrete Spalling by Resurfacing The Concrete

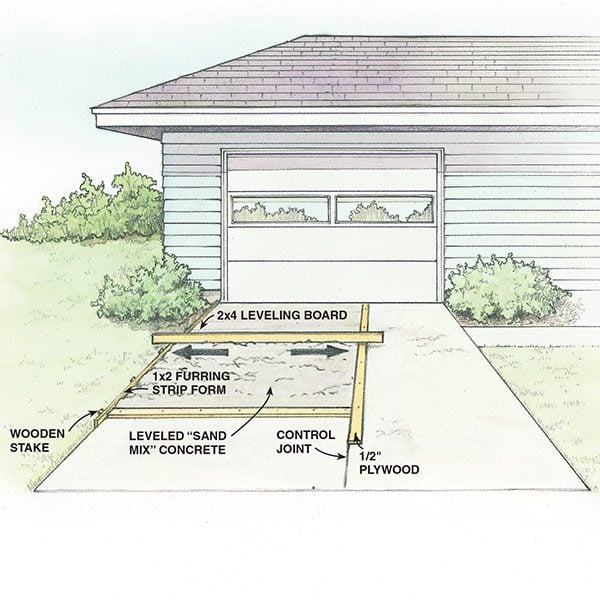

How to Resurface Your Spalling Concrete Driveway

- Here’s the short course on how to install a concrete overlay: Stake 1×2 furring strips along the edges of the driveway or patio, keeping them 1/2 in. above the existing surface. “Picture frame” the section by nailing 1/2-in. plywood strips, flat to the concrete, along the control joints. Mix one part Type 1 Portland cement and one part fine sand by volume. Add water until the mixture is th…

Required Tools For This Project

- Have the necessary tools for this DIY project lined up before you start—you’ll save time and frustration. 1. Bull float 2. Circular saw 3. Concrete edger 4. Drill/driver - cordless 5. Garden hose 6. Hammer 7. Knee pads 8. Paintbrush 9. Power washer 10. Pry bar 11. Safety glasses 12. Sawhorses 13. Screw gun 14. Shovel 15. Speed square 16. Stiff-bristle pushbroom 17. Table sa…

Required Materials For This Project

- Avoid last-minute shopping trips by having all your materials ready ahead of time. Here’s a list. 1. 1/2-in. plywood strips 2. 1x2 furring strips 3. 2x4 leveling board 4. Concrete nails 5. Type 1 Portland cement 6. Wooden stakes