Completely repair a broken motorcycle crankcase

- Start by sanding the motorcycle housing Okay, let's get down to business with the first step, which is sanding. ...

- Use special resin Indeed, it is now so much to apply your resin loaded with metal and it will be necessary to be meticulous and patient. ...

- Sand the resin to finish the repair ...

How do you fix a cracked engine case?

Best Way To Repair Cracked Engine Cases Aluminum engine cases can be Stick welded, MIG welded, or TIG welded. They can also be gas-welded by a process called aluminum brazing. Because of the high thermal conductivity and low melting point, distortion and burn-through are common when welding aluminum cases.

What is the best way to clean the crankcase?

Kerosene is a good cleaner to flush out the crankcase, because its a thin solvent but still a lubricant. Aluminum and aluminum alloys should NOT be cleaned with caustic soda or cleaners with a pH above 10, as they may react chemically.

How to quote for a crankcase overhaul?

General industry practice is to quote an overhaul based on a serviceable crankcase, serviceable meaning it might have cracks or need repairs for which there wont be an upcharge. But ask the overhaul shop about this before committing.

What is the most common crack in the engine case?

In Continental engines, the most prevalent crack emanates from a cylinder stud. On the O-470 and O-520 engines, sandcast cases are less prone to cracks than later Permold cases with front mounted alternators.

Can you JB weld a cracked crankcase?

In most cases welding a crankcase in the traditional way is not an option especially while it is still on the bike as they are generally alloy and contaminated by oil – that's another reason JB Weld is such a good alternative and permanent repair option.

Can a crank case be repaired?

No matter how much time is on the engine, splitting the case to fix a crack and reassembling it makes little sense. A full overhaul or reman is the way to go. But it can be a little tricky economically. Shops have been weld-repairing cases for years, with good results.

What causes a crankcase to crack?

While there are a number of problems that can result in a cracked engine block, most involve excess heat, which is usually caused by an issue with coolant. When this occurs, the overheated portions of the engine expand, while the cooler areas do not.

Can you JB Weld a engine case?

4:066:20How to use J&B Weld On a cracked engine case - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd as I said I only had a little hole here in the middle but I'm just gonna JB. Well the entireMoreAnd as I said I only had a little hole here in the middle but I'm just gonna JB. Well the entire thing I'm gonna give basically a little bit of a mass.

Can you weld an aluminum engine block?

The selection of the right filler metal is critical in TIG welding aluminum. Most cast aluminum engine components are made from a casting alloy called A356. When welding aluminum, anything higher than 150 degrees Fahrenheit is considered a high-temperature application.

How do you fix an engine casing?

14:4016:32Motorcycle Engine Case Repair! - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo after machining. Or actually after cleaning welding machining drilling and cleaning up withMoreSo after machining. Or actually after cleaning welding machining drilling and cleaning up with various files. And tools and everything else. This is what we've got.

Can you seal a cracked engine block?

With a replacement block costing thousands, it's well worth trying to fix the problem with K-Seal before going down this route. K-Seal will seal the cracks in engine blocks that cause coolant leaks, to get you back on the road and save you a small fortune.

Will a cracked engine block still run?

No, you cannot drive with a cracked block. While your car might technically go for a short period with a cracked block, it is dangerous for you and others on the road. Plus, you will do more damage to the vehicle, leading to an even higher repair bill. You can cause cracked heads, bent pistons, and more damage.

Where is cracking most likely to occur on a crankshaft?

Crankshaft fracture usually starts at the smallest crack, and most of the cracks occur at the fillet of the head cylinder or the end cylinder connecting rod journal and the connecting part of the crank arm. In the course of operation, the crack gradually enlarges and suddenly breaks when it reaches a certain extent.

Does JB Weld expand and contract with heat?

The original J-B Weld is heat resistant, but J-B Kwik is not. J-B Weld does not shrink when it is hardened, but J-B Kwik does.

How Good Is JB weld on aluminum?

For a reliable aluminum epoxy that can handle medium- to heavy-duty jobs, the J-B Weld KwikWeld epoxy has a 5,020 PSI rating and withstands temperatures of over 500 degrees Fahrenheit, making it an ideal option for cars, RVs, and boats.

Does JB Weld work on metal?

J-B Weld Original is waterproof, petroleum, chemical and acid resistant once fully cured. Surface Applications: Metal, Plastic & PVC, Wood, Concrete, Ceramic & Tile and Fiberglass.

What does the crankcase cover do?

0:194:21How a Small Engine Crankcase Breather Works and How to Quick ...YouTubeStart of suggested clipEnd of suggested clipCover the main function of the crankcase breather system is to relieve pressure in the crankcase.MoreCover the main function of the crankcase breather system is to relieve pressure in the crankcase. Created by the piston.

How do you fix a crankcase on an ATV?

4:5310:00Fixing a Cracked Motorcycle Engine Case / TS185 - YouTubeYouTubeStart of suggested clipEnd of suggested clipI apply the jb weld to both sides. The piece that broke off and the whole engine. Case. We're notMoreI apply the jb weld to both sides. The piece that broke off and the whole engine. Case. We're not stuck on there pretty well you got a nice solid.

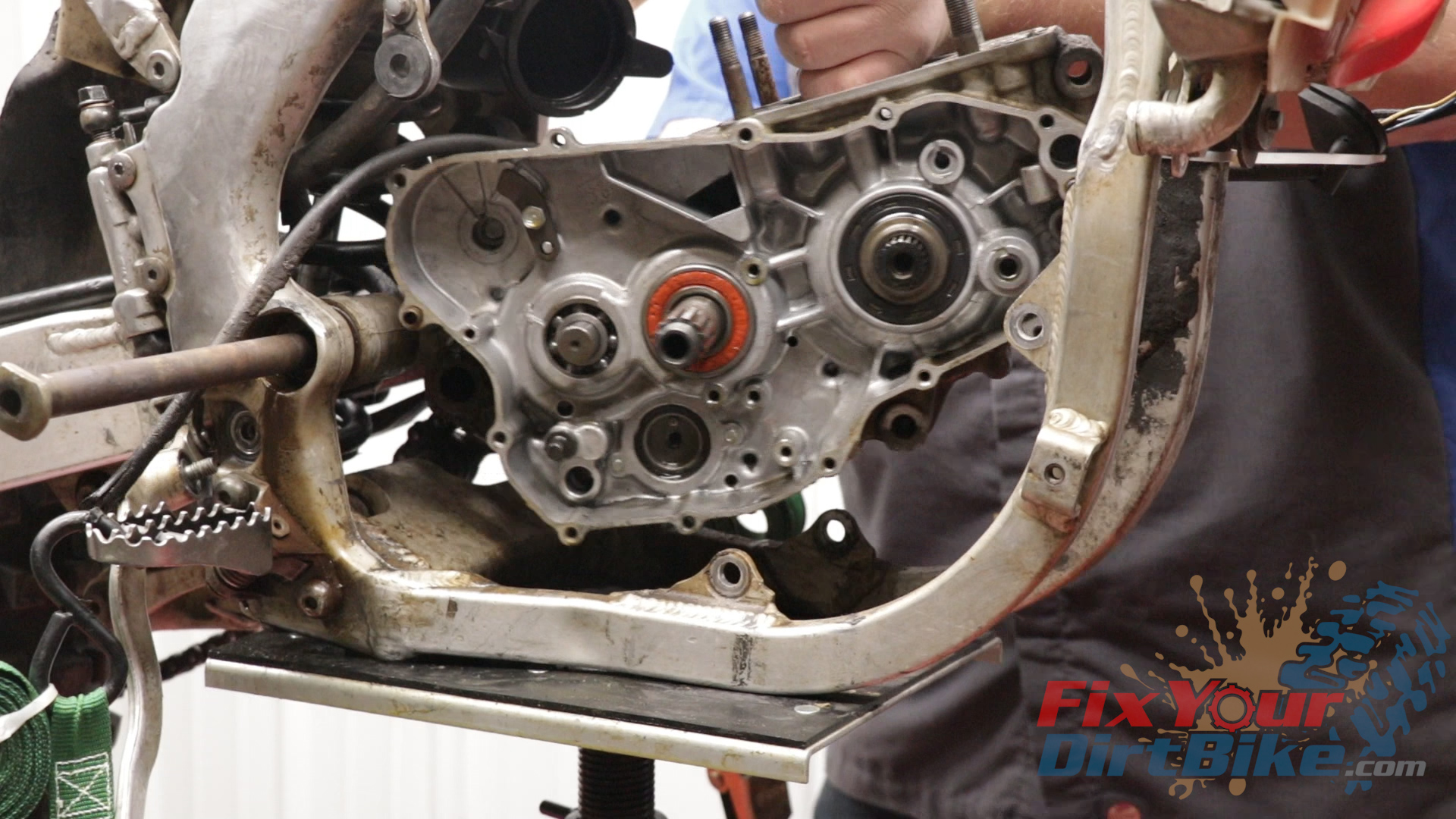

What is the function of the crankcase?

The crankcase is the central component in the engine. It houses the entire crank mechanism including pistons, cylinders and connecting rods. Accessories, the transmission/gearbox and the engine control system with cylinder head are attached to the crankcase.

What is a crankcase on a motorcycle?

The crankcase houses a motorcycle's crankshaft and transmission components.

What to do if you suspect a crack in a metal case?

If a crack is suspected, the area has to be steam cleaned and bead blasted to bare metal and if a line is still indiscernible, a dye penetrant such as Zyglo or a Magnaflux inspection will be employed. If a crack is suspected, the shop might remove some material with a sanding disk to reveal an oil infused crack. The crack is then ground without penetrating the case. If this must be done, its done from the inside of the case.

What causes cracks in a 6 cylinder engine?

These larger engines create stress areas through torsionals in the engine itself and between the airframe and engine. The sheer number of combustion events probably aggravates this. In Continental engines, the most prevalent crack emanates from a cylinder stud. On the O-470 and O-520 engines, sandcast cases are less prone to cracks than later Permold cases with front mounted alternators. Changes in the case design, such as the humpback Phase III castings and the Phase IV products with the seventh cylinder stud seem to crack less, but that doesnt mean they dont crack. An interesting consensus of the shops we interviewed is that the older narrow-deck cases are better than all but the very latest versions, so if youre looking for a replacement case on the used market, dont be afraid of an older one thats in serviceable shape.

What to ask a distributor about when collecting engine quotes?

If youre dealing with a distributor on a rebuild or a new engine, ask the distributor about experience with the two majors on core charges. You may hear a different story than we have and the latest data is usually the best data on core policies. The stated policy may very well be different from what the factory actually does.

How much does it cost to repair a weld?

For example, most shops inspect, weld and recertify a small-displacement Lycoming or Continental for around $700 to $800.

What owners need to understand about case repairs?

What owners need to understand about case repairs is that the process is more involved than just grinding out the cracked metal, building it up with welding and

Why do studs break off?

Occasionally, a stud will break off in the case if vibration or stress become too high.

Can a mechanic damage a case?

By running a second thread or encircling bolt or stud holes, the additional thickness spoils torque readings and can lead to fretting which will have to be machined off at the next overhaul. If its bad enough, it can render a case unserviceable.

I Put A Hole My Crankcase Cover Because I Crash A Lot!

I’ve cracked a few crankcase covers over the years, but this is the first time I’ve managed to crack one from inside of the cover.

Patch Follow Up

For this video, I used JB Weld Extreme Heat Temperature Resistant Metallic Repair Paste.

I Contacted JB Weld About This Issue

I recently used your Extreme Heat to repair a crack in my dirt bike’s crankcase cover. The patch did not hold, and after removing the crankcase cover to double-check my work, the paste could be removed with my fingernail.

What to do after a cracked engine case is repaired?

After the cracked engine case is repaired, there may be some distortion. Check the case edges and mill or file flat if needed. If non-original flywheels and rods are being fitted to the engine cases, line boring or honing should be performed, or misalignment and rapid bearing wear may result. Checking the main bore alignment should be the first procedure done after any major welding is performed.

How to repair a cracked motorcycle case?

To repair cracked cases correctly, the case halves need to be separated, which requires the top end of the motor to be removed. Then the cases have to be made spotlessly clean. The final step is the most important, and that is to find a qualified welder.

How to clean engine cases?

Use an organic solvent such as acetone, a citrus-based degreaser, or a strong soap. Rinse with hot water and dry thoroughly before welding. No matter what process you use to clean them, engine cases will often ooze oil from the pores of the metal when heated .

What is motorcycle engine casting?

Motorcycle engine castings are often a combination of aluminum/silicon cast, or a cast-iron alloy, or a pressure die-cast aluminum. Some are a good quality and others are very porous. Some castings aren't very weldable. Before getting your engine case repaired, try to find out which type of alloy your engine cases are.

Can aluminum brazing be used to replace aluminum?

Because of the low heat input required and flux build-up, aluminum brazing will not always be the best solution. It cannot be used to replace chunks of missing aluminum.

Can aluminum be brazed?

Unlike epoxy, the alloy bonds to the aluminum. This creates a metal repair which can be machined and can withstand impact. Because of the low heat input required and flux build-up, aluminum brazing will not always be the best solution. It cannot be used to replace chunks of missing aluminum.

How to Fix a Cracked or Broken Dirt Bike Engine Case

From the dealer, the price of a case can be horribly expensive. If the case is shattered, it is a little tougher job. If it is just cracked, it is an easy job. YouTube

Small Cracks

Using J-B Weld, do the same sort of application as above. Clean everything with brake cleaner. Grind the edges of the crack back a little on both the inside and the outside of the case. Heat up the oven, coat with J-B Weld, and bake for 30 minutes. Clean the other side, J-B Weld, and bake 30 minutes. Sand flat, paint, and re-attach the case.