Fiberglass Transom Repair

- Step 1: Before beginning removal: Take measurements of all the parts around the transom; fiberglass thickness of outside skin, plywood thickness, inside transom skin thickness, stringer location, stringer thickness, etc ...

- Step 2: Gain access to transom skin and core: The next step is to gain access to the transom so you can remove the rot. ...

- Installing the new core: If you are changing anything about the design of the transom (higher engine mounts, enclosed transom, bracket, etc...) you may need to make adjustments to the ...

- Before final glassing of core: The gaps between your new core and the sides/bottom of the hull will need to be filled with putty. ...

- Tabbing unto the hull bottom and sides: The next step is the tabbing of the transom core to the sides and bottom of the hull. ...

How to replace a transom?

Transom Replacement With a Plywood Core

- Prep Work: Before beginning demolition: Take measurements of all the parts around the transom; fiberglass thickness of outside skin, plywood thickness, inside transom skin thickness, stringer location, string ...

- Gain Access to the Transom. The first step is to gain access to the transom. ...

- Removal of Old Plywood Core. ...

- Install New Plywood Core. ...

- Fill Gaps. ...

How to reinforce a boat transom?

Step-by-step Guide in Reinforcing Fiberglass Boat Transom

- Things that you need to do before removal of the damaged transom. Before dismantling damaged parts, you have to take measurements of the parts around the transom. ...

- Getting into the transom and core. It’s time to get rid of the rot! ...

- New core installation. The new core should have a similar thickness to the original plywood. ...

- Refining your work. ...

- Tabbing. ...

How to rebuild a boat transom?

entire inside of the transom. The next step in the rebuild is the removal of the old plywood core and inside fiberglass transom skin. You will need access to the entire transom plus at least 12" up the side and bottom of the boat. Depending on the boat's construction, you may be able to remove the deck cap, or you may need to make a cut through the

How to fix a rotted transom on your boat?

Repairing Fiberglass Powerboat Transoms - Epoxywork

- The process taken to Refit the Transom back on to the PVC tubes. 1. Zodiac Transom and transom fittings which were removed by hot air gun. 2. ...

- um jon boat with a wood transom that needs replacement means possibilities, such as making the transom taller to accommodate a long-shaft outboard. ...

- Joined Aug 2, 2010. ·. 1,084 Posts. #5 · Aug 1, 2017. ...

Can you fix a fiberglass transom?

Label the pieces and dry fit them to the transom. Plan the cuts in each layer so the pieces are small enough to fit through the opening in the transom. Glue the layers in place. Replace the fiberglass skin and install new plywood core.

Can you fix a cracked transom on a boat?

RE: Cracks in Transom I would open up the crack and seal it off. After you do that, you can gelcoat or screw a nice piece of aluminum on top of the transom. You might also want to remove your motor and see if there is any moisture in the bolt holes going through the transom.

How do you reinforce a fiberglass boat transom?

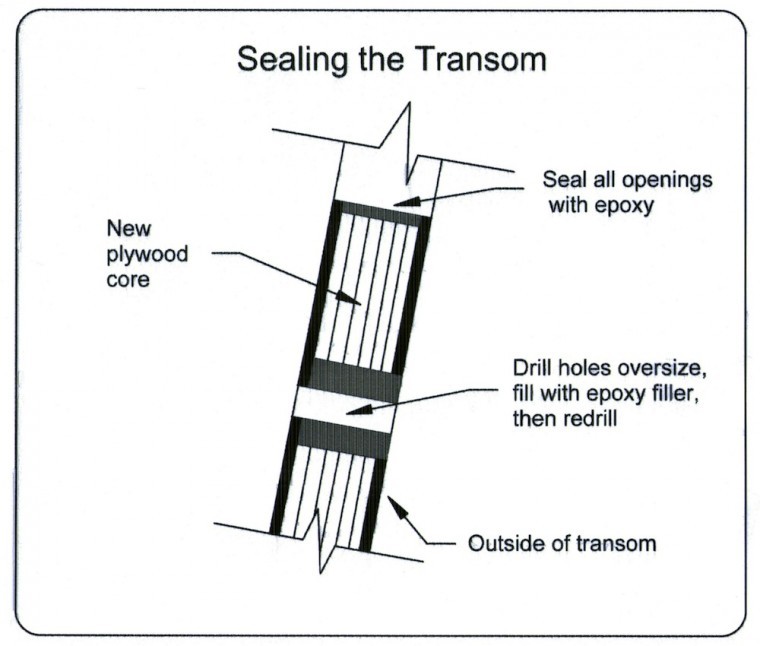

Apply epoxy to the edges of the outer fiberglass skin of the transom and over the heads of the screws holding the skin to the plywood, and lay a strip of fiberglass cloth over the epoxy. Once the fiberglass has cured, repeat this step until four layers of fiberglass and epoxy have been applied.

How do you fix a transom on a boat?

4:0238:35The Easiest Way To Replace A Boat Transom - YouTubeYouTubeStart of suggested clipEnd of suggested clipYou know if you had someone actually replace this transom for you you're talking here from twoMoreYou know if you had someone actually replace this transom for you you're talking here from two thousand to five thousand dollars possibly.

How much does it cost to rebuild a boat transom?

In boat repair circles it is a job for a professional yard — tear the old transom away and replace it. This is usually estimated at a cost somewhere between $2,000.00 and $5,000.00 or more depending on the size of the boat.

How do you repair a rotten transom?

One method is to use a product like Git-Rot from BoatLIFE. This two-part liquid epoxy fills and restores the dry rot inside the wood using capillary action to penetrate it without drilling it full of holes. You can inject Git-Rot directly into the wood for more thorough penetration.

How do I make my transom stronger?

4:2213:05SUPER STRONG Transom Support Build - YouTubeYouTubeStart of suggested clipEnd of suggested clipHere. So to tie these top tubes into this corner bracket system that i'm building i've got someMoreHere. So to tie these top tubes into this corner bracket system that i'm building i've got some heavy wall inch and a quarter pipe which is just a little bit bigger than the diameter of these up top.

What is the best material for a boat transom?

Coosa Board is high density polyurethane foam with reinforced layers of fiberglass. The result is a material equally or superior in rigidity at a fraction of the weight of plywood. It is truly the premier decking & transom material in the marine industry.

How thick should a boat transom be?

As for Thickness, 3 layers of 3/4" composite, skin,bonding laminates and tab layer should work out around 3 inches.

How long do transoms last?

On to fabricating the replacement transom: Most, if not all wooden transoms in smaller boats are made of plywood. From the looks of the transom in this boat, I would estimate a typical transom will last about 20 years or so before they need to be replaced.

How do you check a transom on a fiberglass boat?

4:4211:515 ways to Inspect the Transom of your Project Boat, Cheap ... - YouTubeYouTubeStart of suggested clipEnd of suggested clipBut what you want to do is you take a hammer. And you just wrap the back of the transom. And itMoreBut what you want to do is you take a hammer. And you just wrap the back of the transom. And it should sound real tight. And firm and this should bounce. Back.

How do you reinforce transom on an aluminum boat?

9:4113:05SUPER STRONG Transom Support Build - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd all we're trying to do is just protect. The steel parts from the aluminum. So we want to giveMoreAnd all we're trying to do is just protect. The steel parts from the aluminum. So we want to give them a layer of paint in between the two so that they don't contact and corrode over.

What is a transom saver?

The transom saver is a device that protects your boat's transom from stress or eventual damage from forces exerted on it by the weight of the outboard while you are trailering it.

What is a transom on a boat?

The cross-section of the stern, where you attach an outboard motor, is called the transom. On the top of the boat are metal fittings called cleats.

How do I apply Git Rot?

5:047:53Using Git-Rot Penetrating Epoxy on Rotted Wood - YouTubeYouTubeStart of suggested clipEnd of suggested clipIf I inject it slowly it's almost absorbing into the wood as quickly as I'm letting it drip into theMoreIf I inject it slowly it's almost absorbing into the wood as quickly as I'm letting it drip into the hole. That's a good sign for me tells me it's starting to really work its way down into the fibers.

Step 1: Before Beginning Removal

Take measurements of all the parts around the transom; fiberglass thickness of outside skin, plywood thickness, inside transom skin thickness, stri...

Step 2: Gain Access to Transom Skin and CORE

The next step is to gain access to the transom so you can remove the rot. Each boat will be a little different, sometimes you will have to cut the...

Before Final Glassing of CORE

The gaps between your new core and the sides/bottom of the hull will need to be filled with putty. After filling the gap, using the same putty, you...

Tabbing Unto The Hull Bottom and Sides

The next step is the tabbing of the transom core to the sides and bottom of the hull. For tabbing, use 1708 Biaxial fiberglass tape. This tape is s...

What to do after you remove the wires from the transom?

After you have removed all the wires, blowers, and "stuff" from the inside of the transom, it's time to de-skin it . I did this with my flush cut saw. (same saw I used to cut thru all the tabbing throughout the entire boat)

When to remove everything from a transom?

After you have pictures that you are satisfied with and maybe a few measurements , it's time to remove everything that is attached to and goes thru the transom.

How to make a hole in a boat hull waterproof?

Use a jigsaw to cut your hole coming from the outside where you already have a hole in the hull. Make sure you cover the inside of the hole with polyester resin too make it more waterproof.

Can you cut thru the hull of a boat?

You'll want to very careful you don'y cut thru the hull of the boat. It is very easy to do in this area as the hull is generally not very thick here. (I found out!) The type of saw I used to flush-cut along the transom and hull.

Can you cover the inside of a new transom?

Once you got the tabbing completed, you are now ready to cover the entire inside of the new transom with fiberglass.

Is marine grade plywood better than treated plywood?

Marine grade plywood is probably better if you have access to it, but i didn't have any nearby. Just make sure it's exterior grade if you don't have access to marine grade plywood. They also have treated plywood but i don't believe that is recommended for marine applications.

Can you rebuild a fiberglass boat transom?

Rebuilding the transom on your fiberglass boat is no easy task but unfortunately it must be done on many older boats, usually due to rot in the plywood core. In this article (and Video) I'm going to show you step by step how to remove your old rotten transom and replace it with a new one.

What is a fillet in a fiberglass transom?

A fillet is a radius of putty that allows fiberglass to make a turn around an angle. Fiberglass and 90 degrees do not fare well together. All inside corners of transom should have a round fillet.

What to use to remove old plywood core?

You must completely remove the old plywood core. A reciprocating saw, grinder, hammer and chisel, flat prybar are good to have. If you have an air compressor, a small air hammer with a wide flat blade is a good investment. Be careful to not inflict damage to the outside fiberglass skin.

Can you laminate a boat core?

It is generally easier to laminate the core outside the boat and bond it into the hull once, but on very large transoms this may not be possible due to weight and difficultly in handling.

How to repair a hole in a boat hull?

To repair a hole in the hull, you may need to get some new core material. Try to match the new core material with the existing core material. Make sure the remaining core material is dry.

How long does it take to paint fiberglass?

The way you’ll do this is you’ll mix up a small amount of resin that you can successfully paint on over the fiberglass within about 15 to 20 minutes. This is about how much time you’ll have before the resin begins to dry and harden.

What are the different types of fiberglass cloths?

Some of these cloths include chopped strand mat, biaxial mat cloth, woven roving cloth, continuous roving cloth, carbon fiber cloths, and the list goes on and on.

What is the core material of a boat?

The core material is just the material that is encapsulated by the fiberglass cloth and resin. Core material on boats is usually balsam wood or a foam core. However, almost any material can become a core material.

What is fiberglass used for?

Fiberglass Basics You Should Know. Fiberglass is a wonderful material that can be used to repair all sorts of things. Learn how to work with fiberglass, and you can repair boats, vehicles, bathtubs, and many other items. You can even learn to create your own parts, canoes, and even coolers. An entire lifetime could be spent learning how ...

What is the best boat to own?

Fiberglass boats are arguably the best kind of boats you can own. They’re lightweight, fun to use, and easy to maintain.

How thick is boating fabric?

These weights will help determine how thick and strong the material is. Popular boating fabric weights are 10 ounces, 6 ounces, 4 ounces, and 1.5- ounce cloths. These fabrics are sold by the yard and generally come in widths between three and five feet.

10 Reasons Why You Should Reinforce a Fiberglass Boat Transom

1) Fiberglass boats can be built with thick hulls and thick bilges, but the transom is usually much thinner than the rest of the boat.

10 Ways on How to Reinforce a Fiberglass Boat Transom

Adding fiberglass to the transom of your boat is very important. When transoms are milled, they often leave a lot of weak spots in the fiberglass that can compromise how well the boat will hold up over time. Fiberglass reinforcement will strengthen these weak areas and help you avoid costly repairs down the road.

Some Tips and Suggestions

1. Fiberglass can be worked on with certain solvents. You’ll want to use the safe ones, not the nasty ones like acetone.

How Can I Strengthen My Old Fiberglass?

Fiberglass is relatively cheap and easy to install, but there are some weak points in all fiberglass components. For example, fiberglass hulls crack when they are improperly installed or when their supporting structures fail. Also, as your boat ages, the gel coat finish may loosen and allow moisture into the wood core of the fiberglass plating.

Can You Replace the Transom on a Fiberglass Boat?

Yes, you can replace the transom on a fiberglass boat. However, the fiberglass work and painting details will be left to a professional. Replacing a transom on a fiberglass boat is a job best left to a professional. You must have the right knowledge and experience to replace the transom. If you do not, you may end up with a boat that leaks.

Conclusion

Fiberglass transom reinforcement is a standard and simple process that anyone can do. It’s an easy DIY project that will increase the life of your boat. If you don’t have any experience with fiberglass, we recommend getting help from someone who does so it doesn’t turn out to be more difficult than necessary.

Outboard Motor on Fiberglass Boat Relies on the Transom

The boat’s transom carries the substantial weight of an outboard motor. It even increases when the vessel accelerates or bounces on the trailer. At the same time, the fiberglass skin and core where the mounting takes place bear this weight.

Step-by-step Guide in Reinforcing Fiberglass Boat Transom

Before dismantling damaged parts, you have to take measurements of the parts around the transom. You have to jot down the exterior skin of fiberglass thickness, interior skin thickness, the location and thickness of stringer, and more. Keep the records for later reference.

Takeaway

It’s a must to look after your boat as it’s an expensive investment. I hope this guide on how to reinforce a fiberglass boat transom will help you immensely in the future. Share this article to help others and you may leave a comment to share your experience. It’s great when boat owners help each other in taking care of their vessels!

How much does a 28 whitewater hull cost?

I was looking for a center console hull that had great seakeeping ability in order to fish offshore in Florida. I found a used 28 Whitewater hull, which was perfect because I wanted to put some low-hour Yamahas on it. A new fully rigged 28 Whitewater costs about $150,000, but I got the hull for $15,000. With engines, I would have a rugged, reliable offshore boat for about $60,000.

Can you cut into corners of a transom?

The key is to not cut into the corners; doing so makes it very difficult to repair and can create a weak spot. When cutting back the knees/stringers that were connected to the transom, I had to cut back until I got past the rotted wood.